By observing the surface of the sample during the corrosion process, no obvious bubbles were found on the surface of the sample. The surface of the test basically maintains the original metallic gloss, and no pitting corrosion and corrosion cracks were found. The corrosion is relatively uniform, which indicates that the high silicon-molybdenum ductile iron has good corrosion resistance.

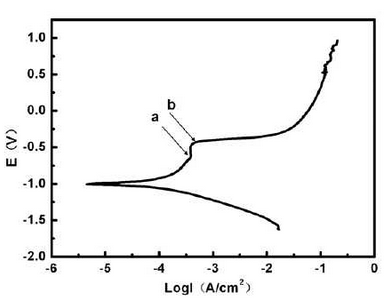

Figure 1 shows the polarization curve of high silicon molybdenum ductile iron in 3.5% NaC solution.According to the polarization curve, the corrosion potential (Ecorr) of high silicon molybdenum ductile iron in 3.5% NaC l solution is -1.002V and the corrosion current (Icorr) is 2.73 x 10-4 and 2.73 x 10-4A-4A/cm2A/cm2.2.As shown in Figure 1, the anode polarizes from point a to point BThe passivation potential (Epp) of high silicon molybdenum ductile iron is about -0.328V. When the anode potential exceeds -0.525V, the surface of the sample completely enters the passivation area. It can be seen from the previous research on the structure that there are uniformly distributed silicon elements in high silicon molybdenum ductile iron, which can improve the pitting resistance of the material, especially the molybdenum element in this cast iron.The addition of Cl-ion inhibits the coexistence of silicon and molybdenum, further improves the corrosion resistance, inhibits the coexistence of silicon and molybdenum in Cl-ion medium and further improves the corrosion resistance.