In the realm of engineering and manufacturing, complexity and precision often go hand in hand. Custom steel casting solutions offer a vital approach to addressing complex engineering challenges by providing tailored components that meet specific design and performance requirements. This article delves into the significance of custom steel casting solutions, their applications, and the advanced techniques used to overcome intricate engineering obstacles.

Overview of Custom Steel Casting Solutions

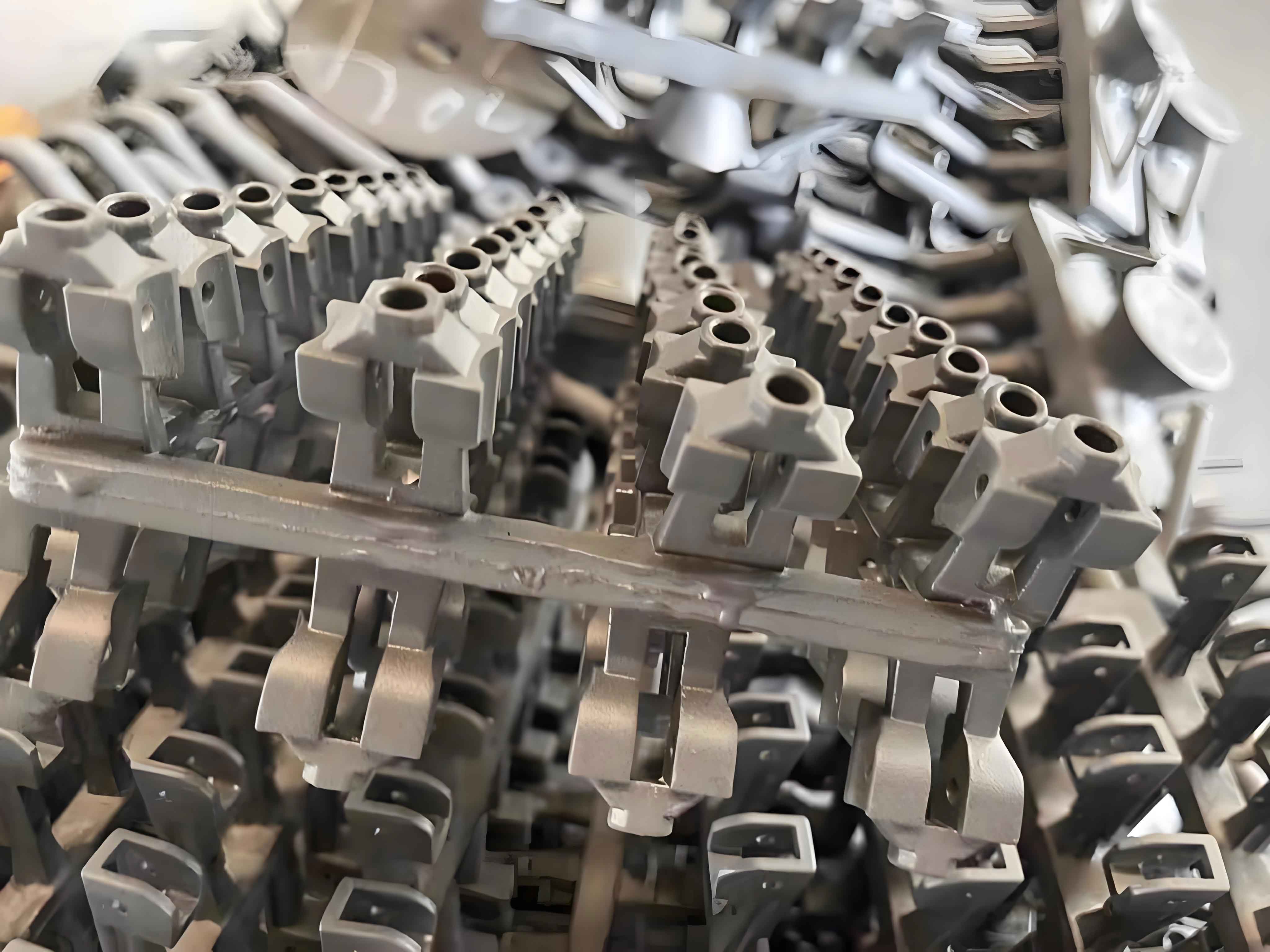

Custom steel casting solutions involve designing and manufacturing steel components to exact specifications, catering to unique engineering requirements. The process encompasses various stages, including:

- Design and Planning: Collaborating with engineers to create detailed designs and specifications.

- Material Selection: Choosing appropriate steel alloys to meet performance criteria.

- Pattern and Mold Creation: Developing precise patterns and molds for casting.

- Melting and Pouring: Melting selected materials and pouring molten steel into molds.

- Cooling and Solidification: Managing the cooling process to ensure proper solidification.

- Finishing and Inspection: Finishing castings through machining and inspecting for quality assurance.

Significance of Custom Steel Casting Solutions

Custom steel casting solutions are crucial for addressing complex engineering challenges due to their ability to provide:

- Precision and Accuracy: Custom castings ensure precise dimensions and tight tolerances, essential for high-performance applications.

- Material Optimization: Selection of specific steel alloys tailored to meet the mechanical properties required for the application.

- Design Flexibility: Ability to create complex geometries and intricate shapes that are difficult to achieve through other manufacturing processes.

- Enhanced Performance: Custom castings often result in improved strength, durability, and overall performance of the final product.

Applications of Custom Steel Casting Solutions

Custom steel casting solutions are employed across various industries to address specific engineering challenges. Some notable applications include:

Automotive Industry

- Engine Components: Custom castings for engine blocks, crankshafts, and cylinder heads designed to withstand high temperatures and pressures.

- Suspension Parts: Precision-cast control arms, knuckles, and links that offer enhanced strength and durability.

Aerospace Industry

- Turbine Blades: Custom steel castings designed to endure extreme temperatures and stresses in jet engines.

- Landing Gear: High-strength steel castings that provide reliability and safety for aircraft landing systems.

Construction Industry

- Structural Components: Custom steel castings for beams, columns, and support brackets that offer superior load-bearing capacity.

- Machinery Parts: Durable castings for heavy machinery, including gears, housings, and frames.

Oil and Gas Industry

- Valves and Pumps: Corrosion-resistant steel castings designed for harsh environments and high-pressure applications.

- Drilling Equipment: Robust castings for drill bits, collars, and stabilizers that can withstand intense operational conditions.

Advanced Techniques in Custom Steel Casting Solutions

To meet the demands of complex engineering challenges, several advanced techniques are employed in custom steel casting solutions:

1. Computer-Aided Design (CAD) and Simulation

Technique: Using CAD software to design detailed patterns and molds, followed by simulation software to predict casting behavior.

Benefits:

- Ensures precision in mold design.

- Identifies potential defects and optimizes the casting process.

- Reduces the need for physical prototyping, saving time and costs.

2. Investment Casting

Technique: Creating a wax pattern coated with ceramic material to form a mold, which is then used to cast steel components.

Benefits:

- Produces high-precision, complex geometries.

- Provides excellent surface finish and dimensional accuracy.

- Suitable for both small and large-scale production.

3. Additive Manufacturing

Technique: Utilizing 3D printing technology to create molds and patterns for custom steel castings.

Benefits:

- Allows for rapid prototyping and iteration.

- Facilitates the production of intricate designs that are difficult to achieve with traditional methods.

- Reduces lead times and material waste.

4. Heat Treatment Processes

Technique: Applying advanced heat treatment techniques such as annealing, quenching, and tempering to enhance the properties of steel castings.

Benefits:

- Improves mechanical properties like strength, toughness, and hardness.

- Reduces residual stresses and enhances dimensional stability.

- Tailors the microstructure of the casting to meet specific performance requirements.

Tables Illustrating Custom Steel Casting Applications and Techniques

Table 1: Applications of Custom Steel Casting Solutions

| Industry | Application | Benefits |

|---|---|---|

| Automotive | Engine components, suspension parts | Enhanced strength, durability, and precision |

| Aerospace | Turbine blades, landing gear | High-temperature resistance, reliability |

| Construction | Structural components, machinery parts | Superior load-bearing capacity, durability |

| Oil and Gas | Valves, pumps, drilling equipment | Corrosion resistance, high-pressure endurance |

Table 2: Advanced Techniques in Custom Steel Casting

| Technique | Description | Benefits |

|---|---|---|

| Computer-Aided Design (CAD) | Designing and simulating casting processes | Precision, defect prediction, cost savings |

| Investment Casting | Using wax patterns and ceramic molds for casting | High precision, complex geometries, accuracy |

| Additive Manufacturing | 3D printing molds and patterns | Rapid prototyping, intricate designs, reduced waste |

| Heat Treatment Processes | Applying controlled heating and cooling techniques | Improved mechanical properties, dimensional stability |

Lists of Challenges and Solutions in Custom Steel Casting

Common Challenges in Custom Steel Casting

- Complex Geometries: Creating intricate shapes and designs can be difficult and time-consuming.

- Material Selection: Choosing the right alloy to meet specific performance requirements.

- Defect Prevention: Ensuring castings are free from defects such as porosity, cracks, and inclusions.

- Cost and Time Efficiency: Balancing high-quality production with cost and time constraints.

Solutions for Overcoming Challenges

- Advanced Design and Simulation: Utilizing CAD and simulation software to optimize designs and predict potential issues.

- Precision Casting Techniques: Implementing investment casting and additive manufacturing for high-precision components.

- Rigorous Quality Control: Employing non-destructive testing methods and real-time monitoring to ensure defect-free castings.

- Efficient Production Planning: Streamlining production processes to reduce lead times and costs without compromising quality.

Conclusion

Custom steel casting solutions are essential for addressing complex engineering challenges across various industries. By leveraging advanced techniques such as CAD, simulation, investment casting, and additive manufacturing, manufacturers can produce high-precision, high-performance components tailored to specific requirements. These solutions not only enhance the mechanical properties and durability of steel castings but also improve efficiency and cost-effectiveness in production. As engineering challenges continue to evolve, custom steel casting solutions will remain a cornerstone of innovation and performance in manufacturing.