For defects visible to the naked eye on the casting surface and the parts with defects found during flaw detection, 10mm shall be made by wire cutting × 10 mm × 10 mm test piece. Then, ultrasonic cleaning of the sample with acetone and absolute ethanol for 2-3 times, 10 min each time, is performed to clean the surface of the sample. Then, dry the cleaned sample and conduct scanning electron microscope observation and energy spectrum analysis.

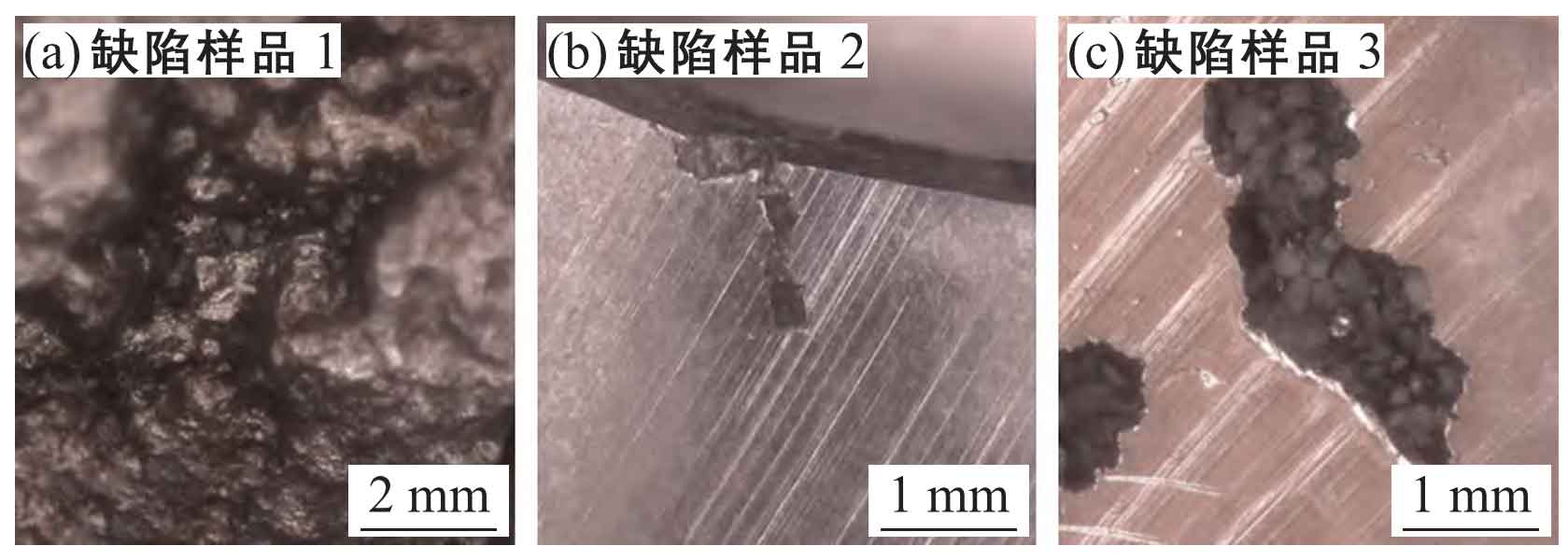

Among them, the scanning electron microscope used for testing is the Phenom ProX desktop scanning electron microscope. There are 3 defect samples cut, of which defect a is located on the surface of the casting (Fig. (a)), and defects b and c are located inside the casting (Fig. (b) and (c)). The morphology of the three defects in the scanning electron microscope optical mode at low magnification is shown in the figure.