Lost foam casting process technology is a major trend in the development of foundry industry in the future. It is in line with the concept of sustainable development advocated by our country. The development prospect of this process is very broad. It has incomparable advantages over traditional casting technology. At the same time, it also meets the requirements of energy conservation and environmental protection advocated now. Its use greatly reduces the pollution of noise, dust and smoke, which also greatly improves the working environment of operators and reduces the labor intensity of operators. It is believed that the development prospect of lost foam casting is very broad.

① Due to the inadequate preparation in the early stage of production, the theoretical negative pressure value of the system is designed to be relatively low, resulting in sand sticking defects in lost foam castings.

② Due to the low temperature of molten metal, the casting of lost foam casting workpiece is not comprehensive, the products after lost foam casting appear cracks or fractures after being subjected to external force, and there are oxidized inclusions at the fracture, and they are not fused together, which is the cause of cold lap (as shown in figure 1).

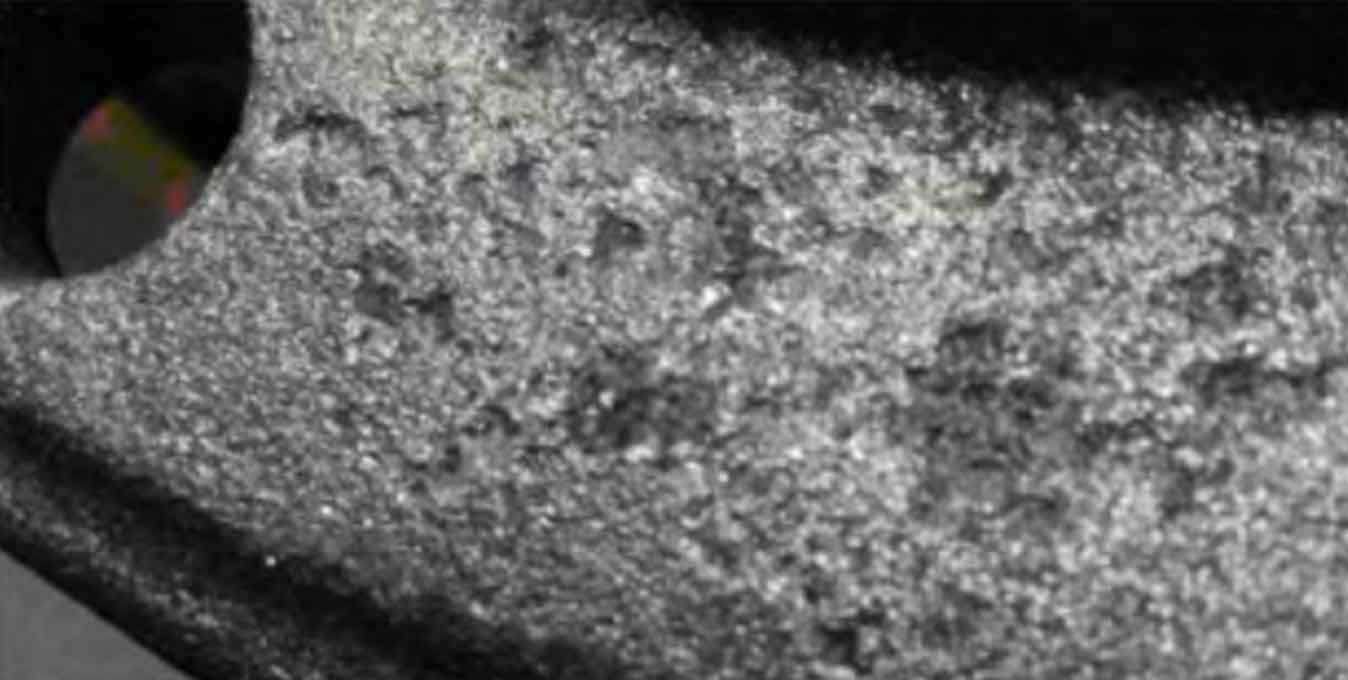

③ The metal oxide of lost foam casting materials and the charge slag and slag of refractory materials. The shape of the slag hole formed by these slag on lost foam casting is irregular. From the appearance color, the slag hole caused by slag is black, while the charge slag hole is indeed white. At the same time, the ladle uses the hot melt of refractory materials, which shows black slag on the surface of lost foam castings, which is the cause of slag inclusion (as shown in Figure 2).