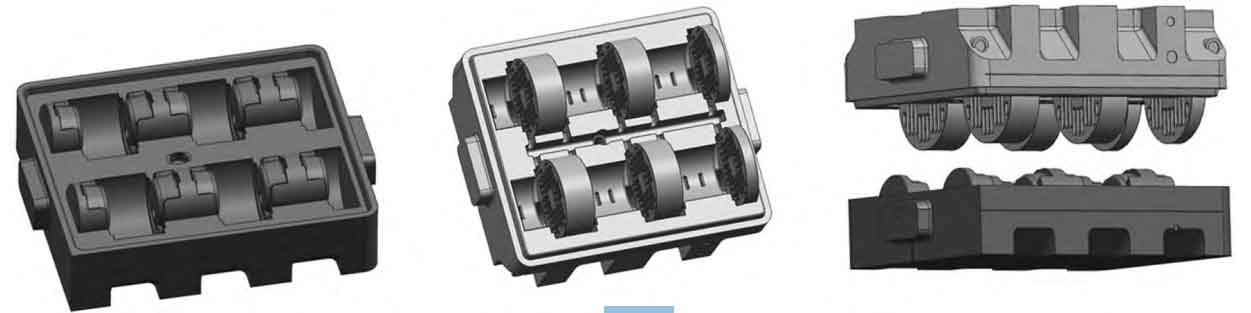

This product is produced using 3D printing sand molds. Therefore, 3D printing technology is fully utilized in the sand mold process design, without considering mold production and mold removal. It can combine mold and core, greatly reducing the number of sand cores, avoiding deviations caused by core assembly and box assembly, high dimensional accuracy, and small machining allowance. The sand mold required for the entire steel casting production is divided into two sand molds, At the same time, all the difficult rib plates of the steel castings are placed inside a sand mold to avoid the problem of the rib plates of the steel castings causing cracks when parting from the middle position during vertical pouring. This improves the appearance quality of the steel castings and reduces the workload of subsequent cleaning, greatly improving and improving the quality and cost. As shown in the figure, print a sand mold map for the 3D of the product.