The function of sand core is to shape the hole, inner cavity or parts that are not easy to produce sand on nodular cast iron. There are many kinds of sand cores. According to different core making processes, they can be divided into conventional sand cores, self heating sand cores, cold core box sand cores and hot core box sand cores.

The basic requirements for the performance of sand core are: sufficient strength and stiffness, good exhaust capacity, no great resistance to the solidification shrinkage of nodular cast iron, and easy sand cleaning in the later stage.

The basic principle of sand core design is: complex sand cores shall be manufactured in blocks, the number of sand cores shall be reduced as far as possible, the strength and exhaust of sand cores shall be ensured, and the box surface of sand cores shall be consistent with the parting surface as far as possible.

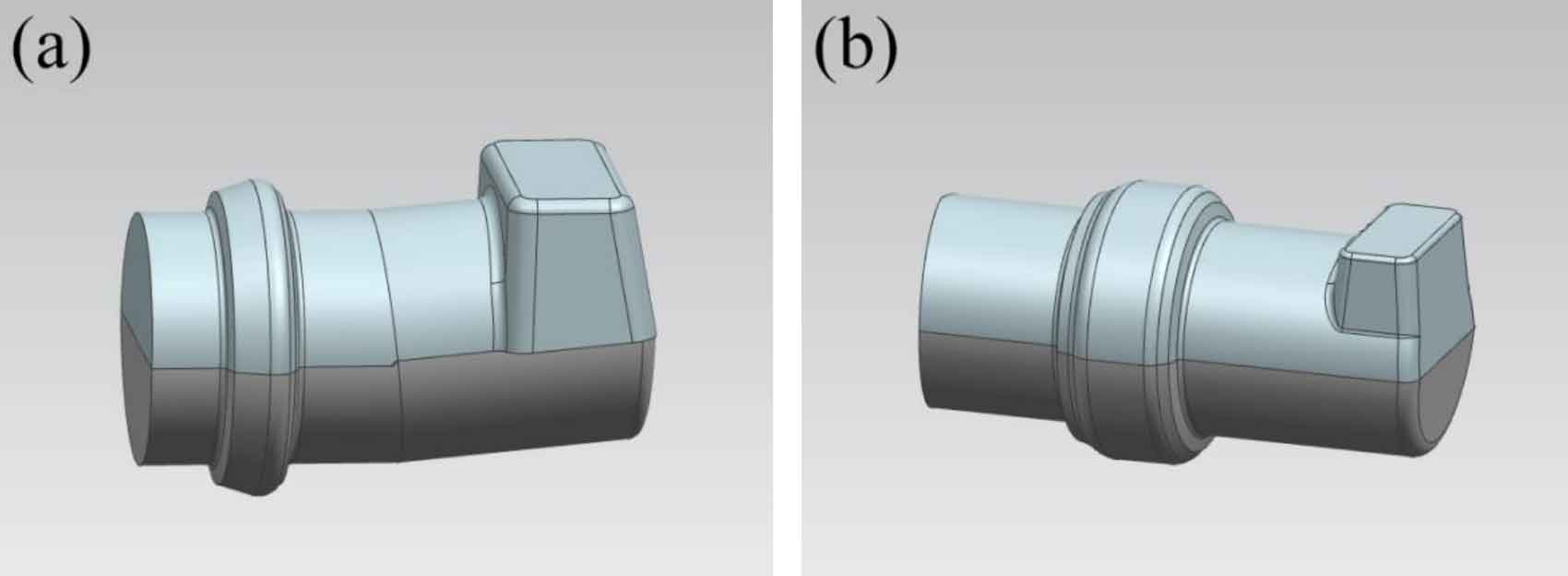

The nodular cast iron of the automobile hub support studied adopts zh760l-25a automatic cold box core shooting mechanism. Due to the different shape and inclination of the two holes cast by the sand core, according to the general criteria of sand core design, the sand core is finally determined as the two forms shown in the figure.