1. Chemical composition

The shell sand casting adopts ZG270-500 alloy, which has certain plasticity and toughness, high strength and hardness, and the microstructure is austenite and ferrite. It has good mechanical processing performance and can also withstand large loads. Its chemical composition is shown in Table 1.

| ω(C) | ω(Mn) | ω(P) | ω(S) | ω(Fe) |

| 0.4~0.5 | 0.7~0.8 | 0.04 | 0.05 | allowance |

2. Structural Model

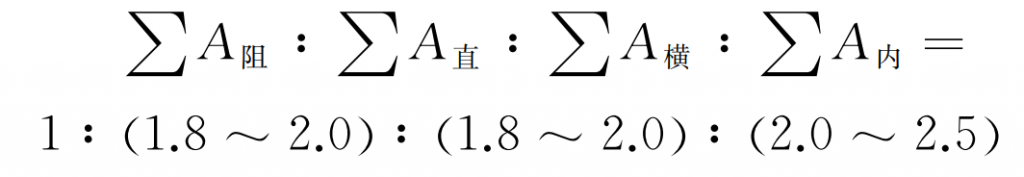

The shell sand casting is hollow, with high requirements for internal surface quality and local thickness. The sand casting has a mass of 392.93kg and an external dimension of 812mm × 525mm × 356mm, with an average wall thickness of 8mm for sand castings. The diagram of the shell sand casting is shown in Figure 1.

3. Pouring System Design

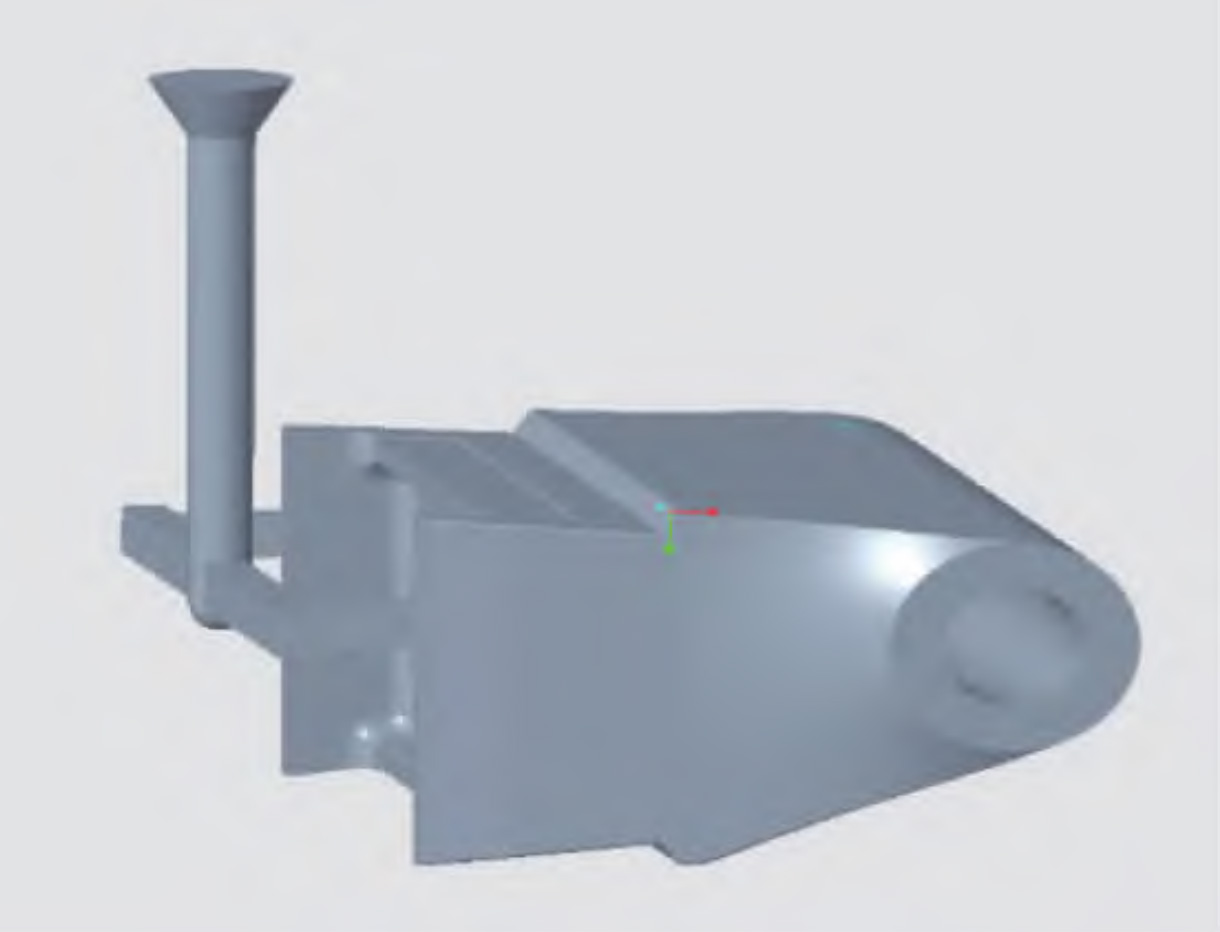

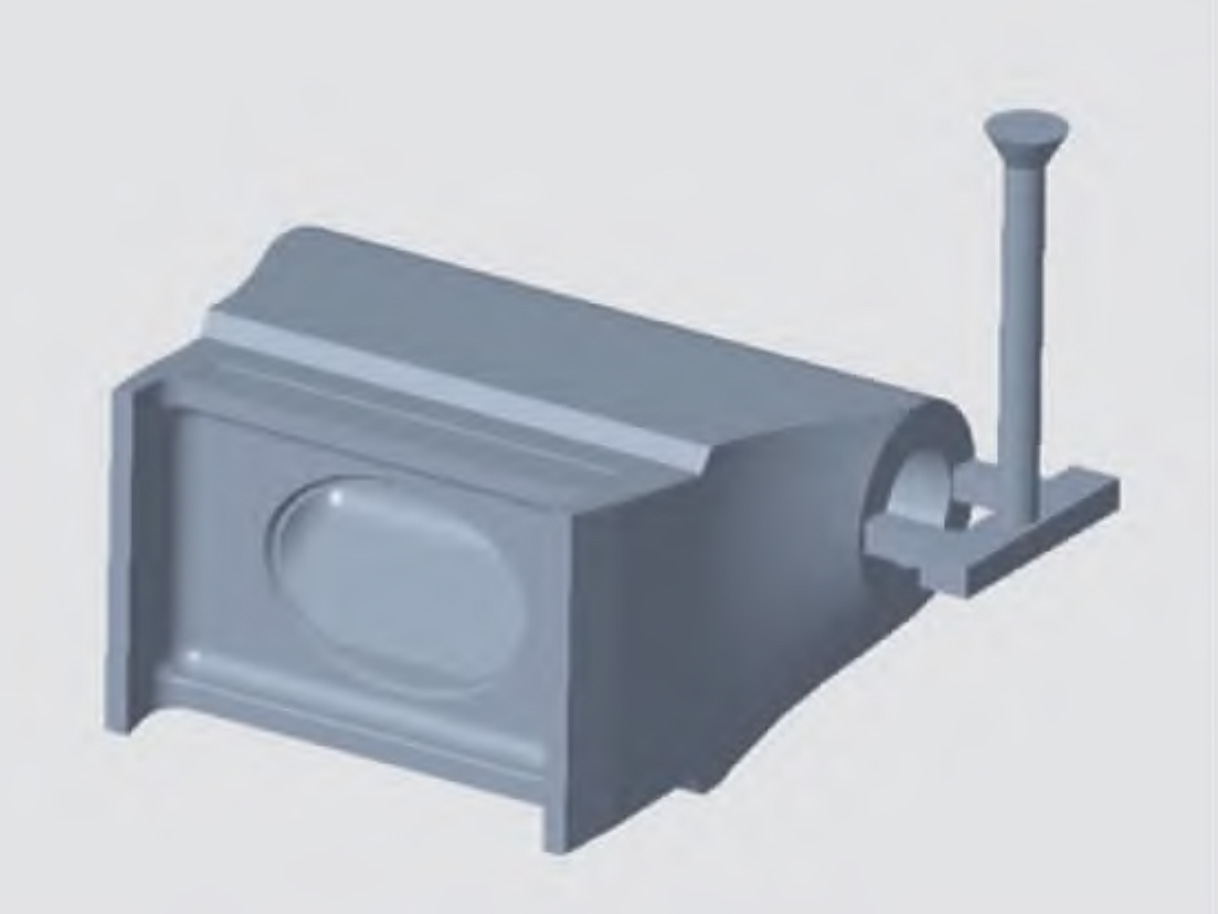

Based on the principle of selecting the parting surface, two sand casting process plans have been preliminarily designed. The first process plan involves designing the inner runner at the base of the sand casting, as shown in Figure 2; The second process plan places the inner runner on the cylindrical part of the sand casting, as shown in Figure 3. These two processes have simple shapes and are easy to operate. Due to the fact that the casting is a steel casting, the gating system adopts an open gating system. The advantages of this gating system are smooth mold filling, avoiding turbulence, and reducing metal oxidation.

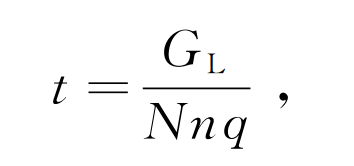

The bottom pouring plug rod steel ladle is used for pouring, with a diameter of 40mm. According to the casting process manual, it can be seen that the average flow rate of the pouring hole is 27kg/s. The pouring time is calculated according to the formula:

In the formula: t is the pouring time; GL is the mass of molten steel inside the mold, GL=450kg; N is the number of pouring bags simultaneously, N=1; N is the number of pouring holes in one ladle, n=1; Q is the average pouring speed.

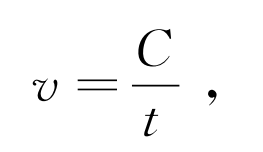

According to the formula, it can be calculated that t=16.7s. Whether the pouring time is appropriate can be verified by the rising speed of the steel liquid in the mold, as shown in the formula:

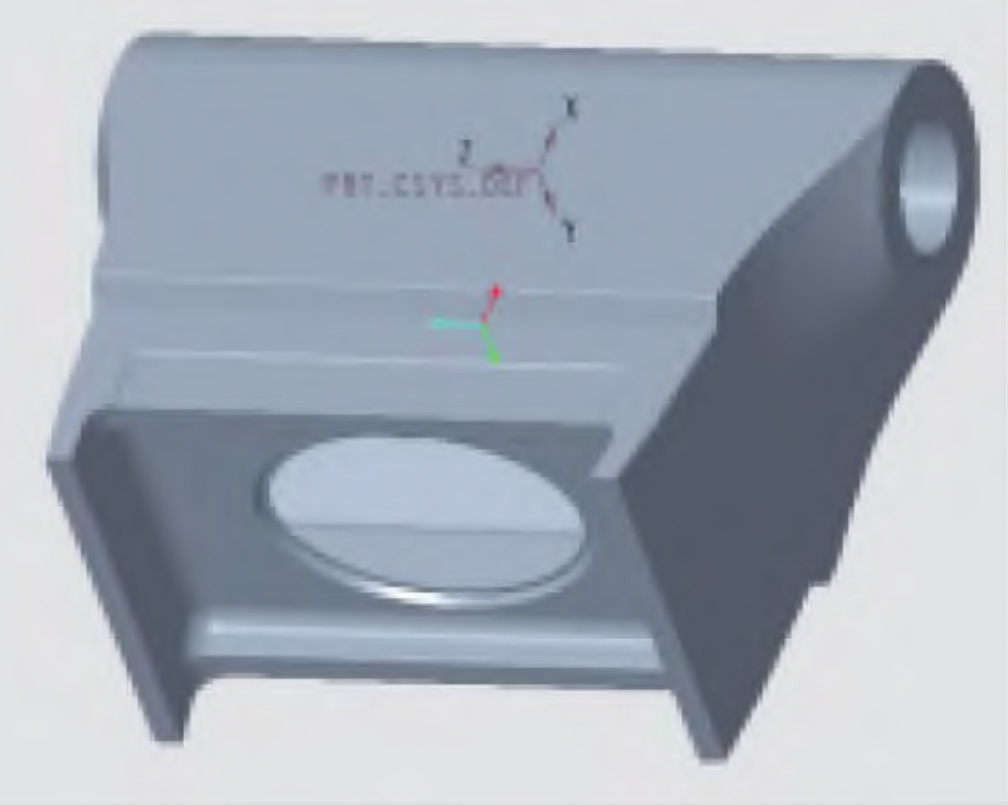

In the formula, v is the rising speed of the molten steel in the mold; C is the height of the sand casting in the mold cavity, C=356mm; T is the pouring time, t=16.7s. According to the formula, the rising speed of molten steel in the mold is 21.3mm/s. The cross-sectional area of each component in the selected pouring system is shown in the formula: