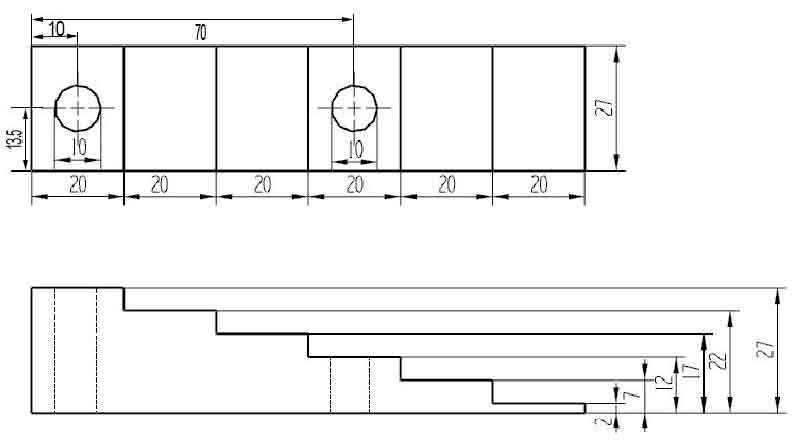

For the SLS fired specimens, the specific dimensions are shown in Figure 1. The size of the sample for selective laser sintering rapid prototyping and post-processing were measured by vernier caliper with accuracy of 0.02mm. The corresponding parts of each step were selected for measurement and the average value was taken. Considering the influence of post-treatment process of wax impregnation on the accuracy of wax pattern, and the specific effect of one two wax impregnation process on SLS rapid investment casting prototype, it is necessary to study the influence of different wax impregnation temperature on the dimensional accuracy and surface quality of specimens.

The main contents of the experiment are as follows: 20 SLS prototype specimens were sintered with the optimized selective sintering process parameters, which were divided into five groups, and their dimensions were measured. Four specimens in each group were immersed in wax at 55 ℃, 60 ℃, 65 ℃, 70 ℃ and 75 ℃ for 20 s. After the specimens were fully cooled, two specimens in each group were immersed in wax at the same temperature for 4 s. Then, the dimensional accuracy of the sample is calculated, and the change rule of the dimensional accuracy of SLS prototype after one-time wax immersion is emphatically analyzed; and the change rule of the dimensional accuracy of the sample after two-time wax immersion is compared with that of the sample after one-time wax immersion. Through the analysis of the change rule of the dimensional accuracy and the change of the surface quality of the wax mold after one-time and two-time wax immersion, the optimal process parameters of wax immersion are obtained All right. Afs-650dg intelligent constant temperature wax dipping machine produced by Beijing Longyuan automatic forming system Co., Ltd. is used as wax dipping equipment, as shown in Figure 2.