The gating system of tractor box castings generally includes sprue cup, sprue, runner and inner sprue. Whether the gating system is designed correctly or not has a great impact on the quality of tractor box castings. When designing the gating system, the structure, technical characteristics and alloy types of tractor box castings should be comprehensively considered.

Design principle of gating system:

(1) The designed gating system shall comply with the solidification principle of tractor box castings. Adjust the temperature distribution in the mold cavity, reduce the casting stress and prevent the deformation, crack and other defects of tractor box castings.

(2) Provide necessary filling pressure head to control the flow direction and speed during filling, so as to ensure the clear and complete outline of tractor box castings.

(3) Make the metal liquid fill the mold smoothly, avoid the entrainment caused by turbulence, avoid splashing and scouring the mold wall or sand core, and have good slag resistance and slag overflow ability.

(4) Make the liquid metal fill the mold cavity of tractor box casting in an appropriate time to ensure that the liquid metal in the mold has sufficient rising speed to avoid sand inclusion, cold shut and other defects.

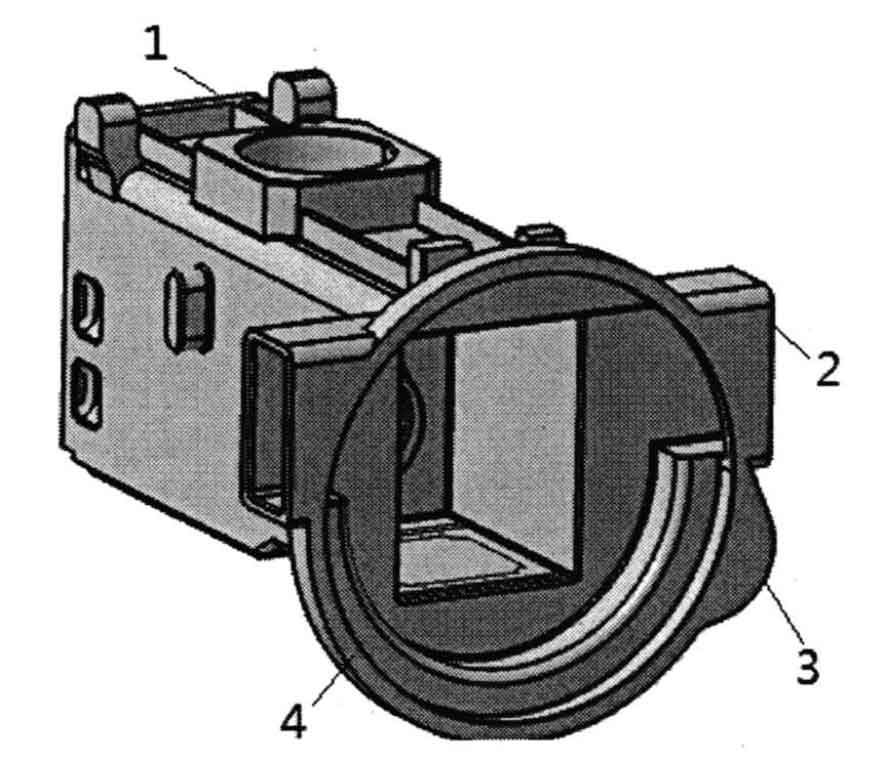

Due to the large size of the reduction box, uneven wall thickness, complex structure and many heat joints, and the main processing surfaces are set in the front and rear of the tractor box castings, the pouring port should be set on the non processing surfaces such as the boss, which is easy to supplement the boss of the tractor box castings to reduce defects. According to the position of the selected parting surface and the structural characteristics that the two sides of the tractor box casting are large planes, it can be seen that the position of the inner sprue should not be set on the planes on both sides. The wall thickness of the planes on both sides is thin, and the sand inclusion defect is easy to be caused by high-temperature baking for a long time. Therefore, the possible position of the inner sprue is 1, 2, 3 and 4 marked in the figure.