The structural types of axle housing can be roughly divided into three types: disconnected type, integral type and combined type. This paper mainly studies the broken sand mold casting axle housing. The feature of the split axle housing is that the whole axle housing is divided into several parts and connected by bolts. Its strength and stiffness are relatively good, and the axle housing and the main reducer housing are divided into two parts. The main reducer gear and differential are installed in an independent main reducer housing to form a separate assembly. After adjustment, they are installed into the axle housing from the front of the middle of the axle housing and fixed together with bolts on the axle housing, so that the disassembly, adjustment, repair and maintenance of the main reducer and differential are very convenient.

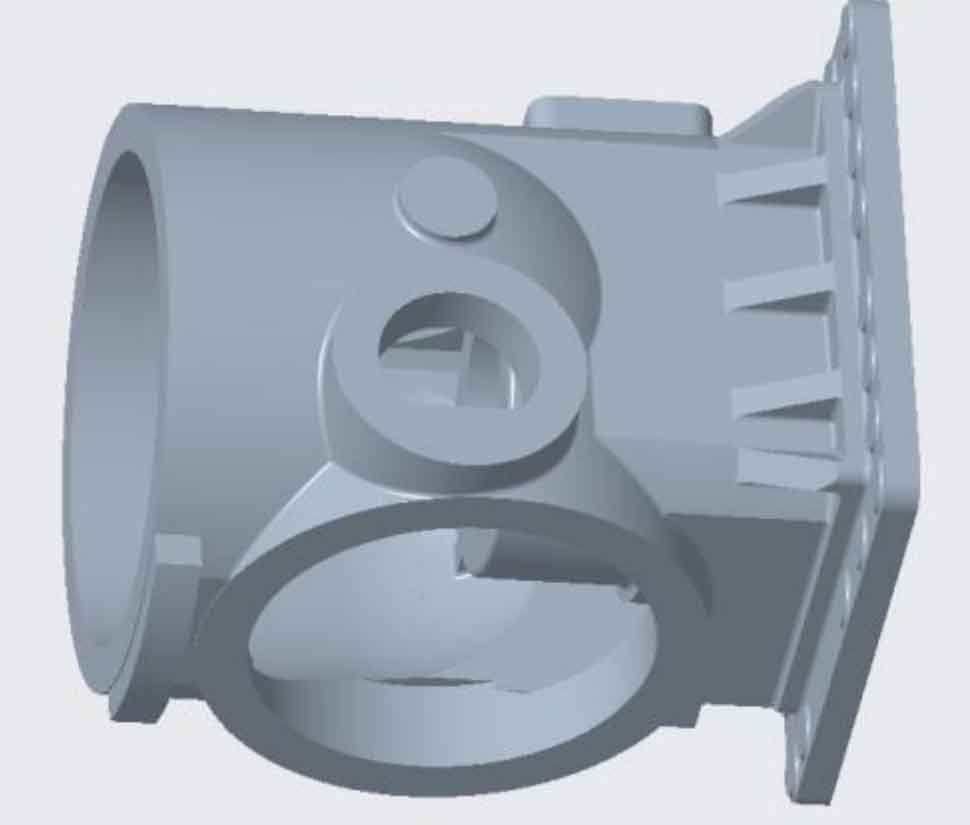

According to the two-dimensional drawing of axle housing parts, Creo three-dimensional modeling software is used for modeling, and the three-dimensional solid graphics of modeling are shown in Figure 1 below.

As can be seen from Figure 1, the overall structure is relatively symmetrical, the part structure is complex, the wall thickness varies greatly, and the main overall dimension is 452 mm × 340 mm × 396 mm, with an average wall thickness of 25 mm, of which the maximum wall thickness is 29 mm and the minimum wall thickness is 15 mm. The axle housing is an important part of tractor axle, and sand casting defects such as shrinkage porosity, shrinkage cavity, crack and cold shut are not allowed.

The solidification of cast steel is characterized by poor fluidity of molten steel, and the wall thickness shall not be less than 8 mm. The pouring system shall be simple and the cutting area shall be larger than that of cast iron. The pouring temperature shall be properly increased to 1520 ° ~ 1580 ℃, because the pouring temperature is high, the superheat of molten steel is large, the liquid holding time is long, and the fluidity can be improved. However, if the pouring temperature is too high, it will cause defects such as coarse grain, hot crack, porosity and sand sticking. At the same time, it is very easy to produce sand sticking defects due to the interaction between molten steel and mold materials at high temperature. Therefore, the artificial quartz sand with high fire resistance should be used as the mold, and the coating made of quartz powder or zirconium sand powder should be brushed on the surface of the mold. In order to reduce gas source and improve liquid steel fluidity and mold strength, most steel castings are sand cast with dry mold or quick dry mold, such as CO2 hardened sodium silicate sand mold.

Because the shrinkage rate of cast steel is much higher than that of cast iron axle housing, in order to prevent the axle housing from sand casting defects such as shrinkage cavity, shrinkage porosity and crack, cold iron, riser and subsidy are mostly used in sand casting process to realize sequential solidification. In addition, the wall thickness of the axle housing shall be uniform, acute angle and right angle structure shall be avoided, sawdust shall be added to the molding sand for casting, coke shall be added to the core, and hollow core and oil sand core shall be used to improve the concession and air permeability of the sand mold or core.

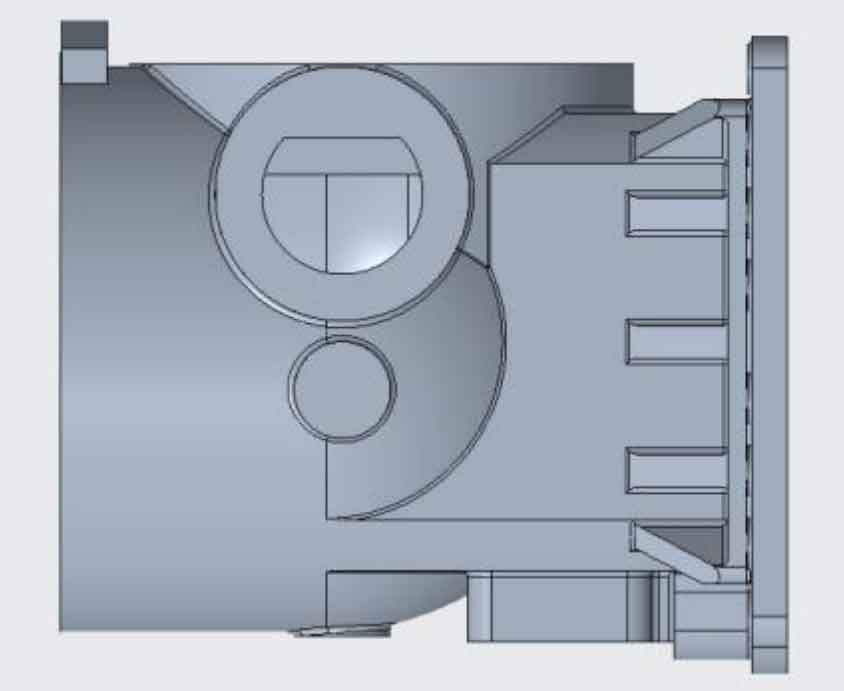

According to the analysis of axle working principle and axle housing blank drawing, the axle housing inner cavity and circular mold wall are important size parts, and the sand casting quality of this part is also emphasized in the actual production process. Therefore, in the sand casting process, the cylindrical mold cavity of the side wall is placed downward, as shown in Figure 2 below, so as to ensure sufficient sand casting quality of important parts of the axle housing, It can successfully produce qualified axle housing.