Generally speaking, the higher the pouring temperature of sand casting, the better the fluidity of alloy liquid and the more conducive to mold filling. Therefore, the easier it is to realize complete mold filling by appropriately increasing the pouring temperature. However, if the pouring temperature of sand casting is too high, it is easy to lead to oxidation and splashing of alloy liquid. At the same time, it also increases the temperature of mold and the time of mold cooling and film removal, which will have a certain impact on the production efficiency of products.

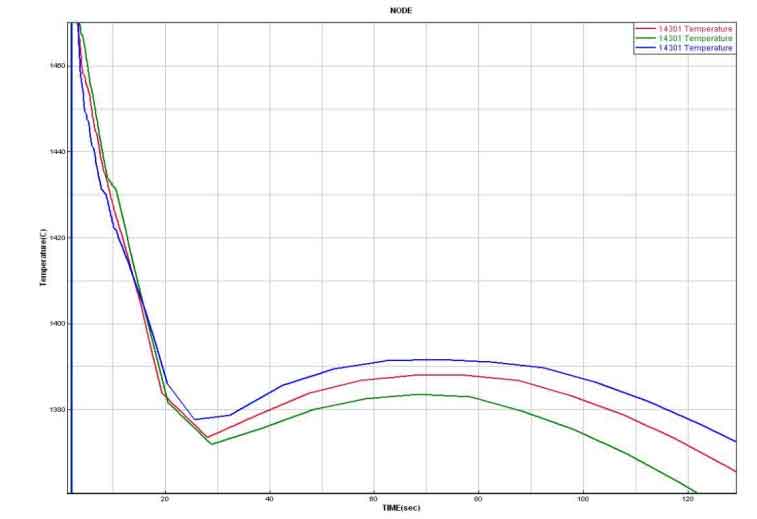

Considering that the reasonable pouring temperature range of materials used for sand casting axle housing is 1540 ~ 1590 ℃; The temperature range of solid-liquid two-phase zone is about 1440 ~ 1510 ℃. The difference of pouring temperature in sand casting has a certain impact on the distribution of thermal stress of castings. The high temperature makes the stress concentration of axle housing more obvious, while the low temperature is prone to insufficient pouring. Considering that the material used for sand casting axle housing is zg40mn, under the same other parameters, the change of every 20 ℃ is simulated. The local temperature change of sand casting is studied when the pouring temperature is 1540 ℃ (green line), 1560 ℃ (red line) and 1580 ℃ (blue line).

It can be seen from the figure that in the 20-30 second mold filling simulation stage, the temperature of 1580 ℃ blue curve decreases rapidly, which is conducive to rapid mold filling, and the cooling is relatively fastest in the temperature range. During the later solidification, in the 80-120 second stage, the solidification speed of 1580 ℃ blue curve is slower than that of 1540 ℃ green curve and 1560 ℃ red curve. The relatively slow solidification speed can avoid the generation of thermal cracks and reduce the trend of stress concentration, which is conducive to the solidification of sand castings. Therefore, the pouring temperature is set to 1580 ℃.