Die casting technology uses the piston to fill the mold cavity with molten liquid metal at high pressure and high speed, and the liquid metal solidifies under high pressure to form the casting. The productivity of die casting is high. The castings formed by die casting have the characteristics of high mechanical properties, high dimensional accuracy and surface accuracy.

Using die casting technology to form automobile cylinder block has high productivity, high dimensional accuracy and surface finish, low scrap rate, but the cost of die casting is high. The die-casting pressure is high and the pressure resistance of sand mold is not enough, so the die-casting mold generally adopts metal mold, and only the cylinder block with open cabin structure can be cast.

Most foreign aluminum alloy cylinder blocks use die-casting technology, and some companies use die-casting technology to produce cylinder blocks. Most domestic manufacturers also use die-casting technology to produce aluminum alloy automobile cylinder block.

Li Jianhua and others studied the influence of the die-casting process on the aluminum cylinder body of the car, adjusted the parameters of the original die-casting pouring process to the low-pressure filling speed of 0.2m/s, the high-pressure speed of 2.8m/s, the low-pressure pressure of 50MPa and the high-pressure pressure of 97mpa, and adjusted the high-speed switching point from 650mm of the original process to 670mm of the current process. When the metal liquid enters the die-casting mold cavity about 15%, the speed of die-casting process parameters is converted to high-speed mold filling, which can make the aluminum liquid fill the mold more smoothly, and the leakage rate of die-casting castings is reduced from 50% of the original process scheme to 20%.

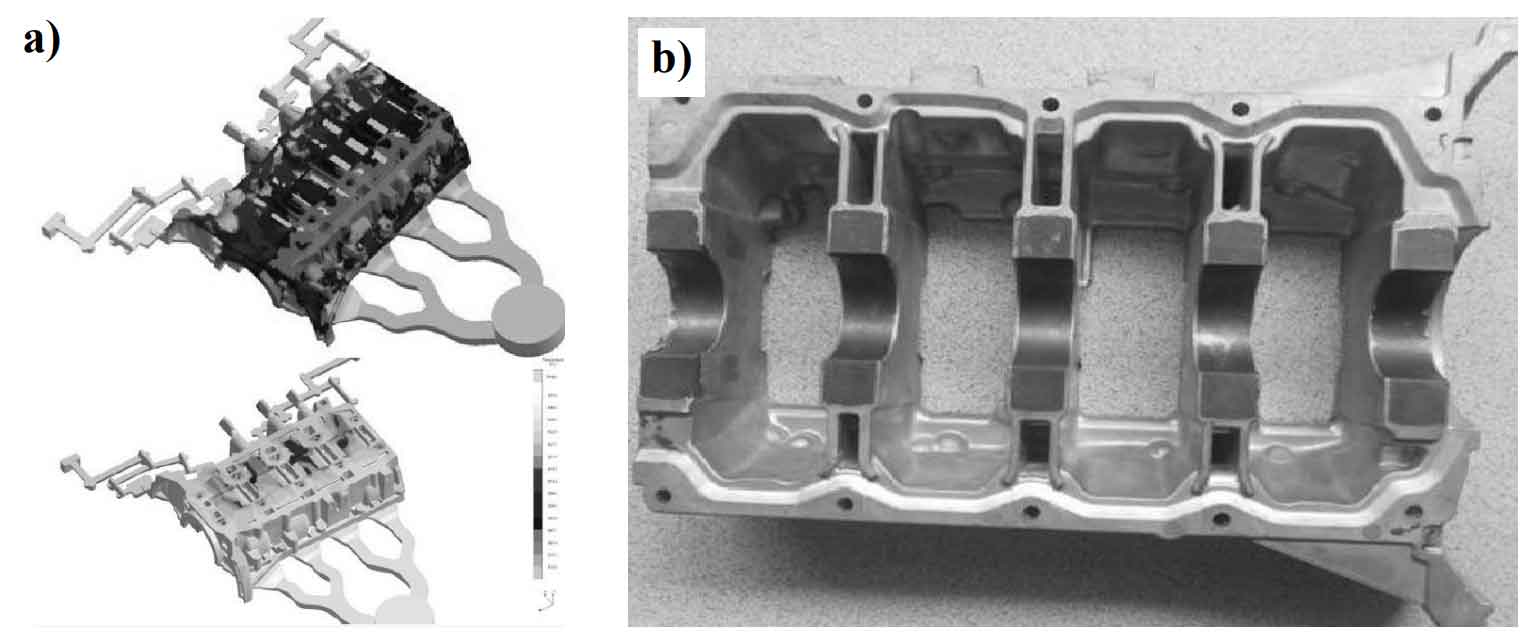

Xie Shuzhong studied the die-casting process of the aluminum alloy lower cylinder and simulated the pouring and filling process of the die-casting lower cylinder. By optimizing and improving the die-casting process, the one-time qualified rate of the die-casting casting casting reached more than 93%, as shown in Figure 1.

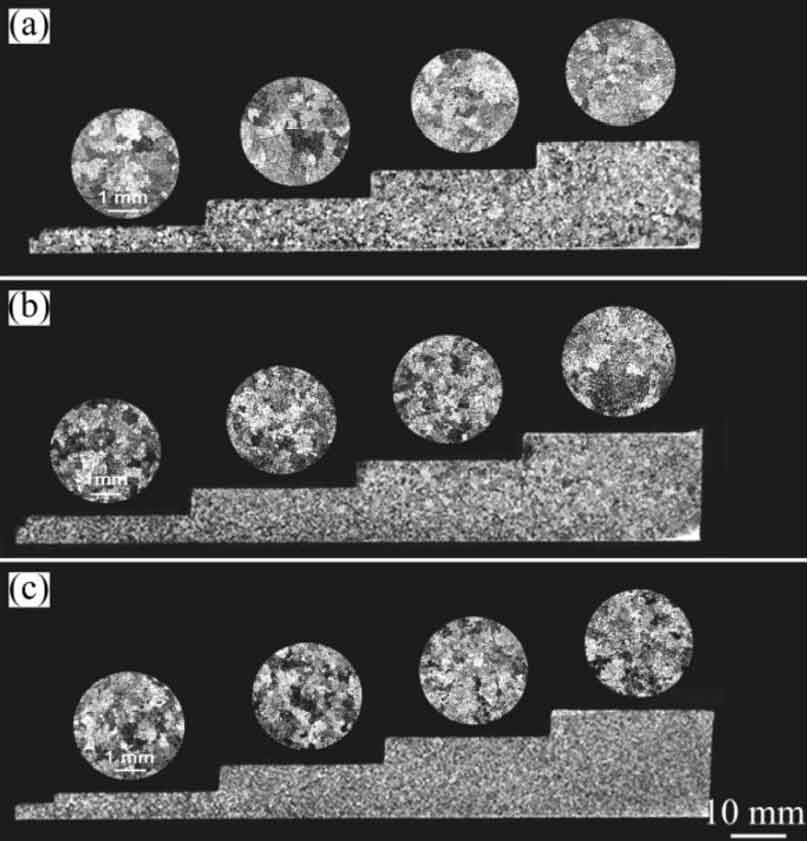

Giordano camicia studied the microstructure and mechanical properties of modified and refined die-casting aluminum alloy cylinder block. Sr modification and Al5Ti1B refinement have fine and uniform microstructure, especially under the condition of low cooling rate, the effect of modification and refinement is more obvious, as shown in Fig. 2.

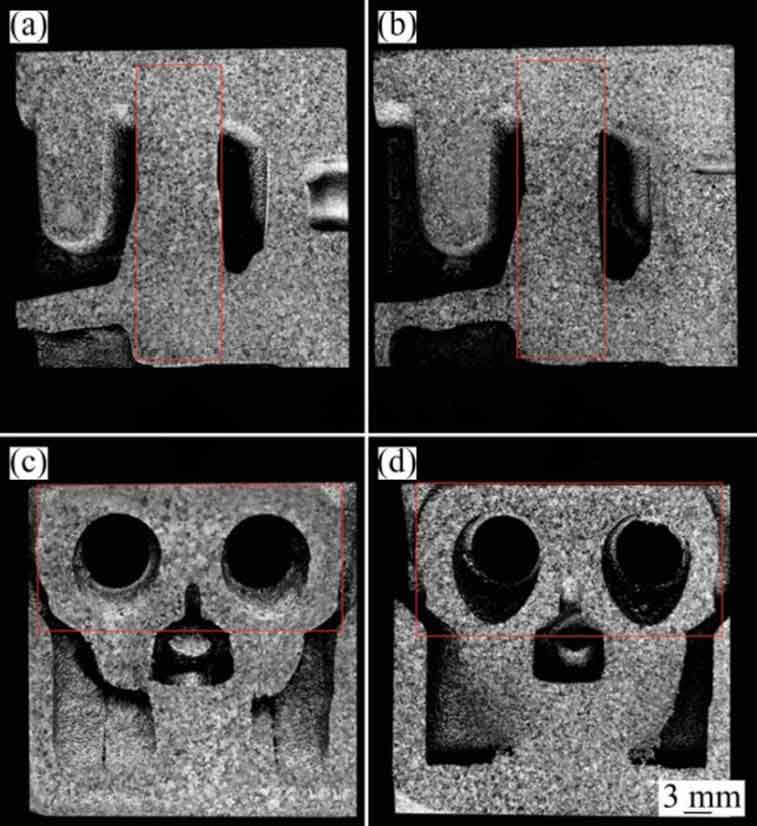

As shown in Figure 3, after refining and modification of the alloy, the microstructure of each part of the cylinder block is the same. It is beneficial to improve the overall performance uniformity of the cylinder block.