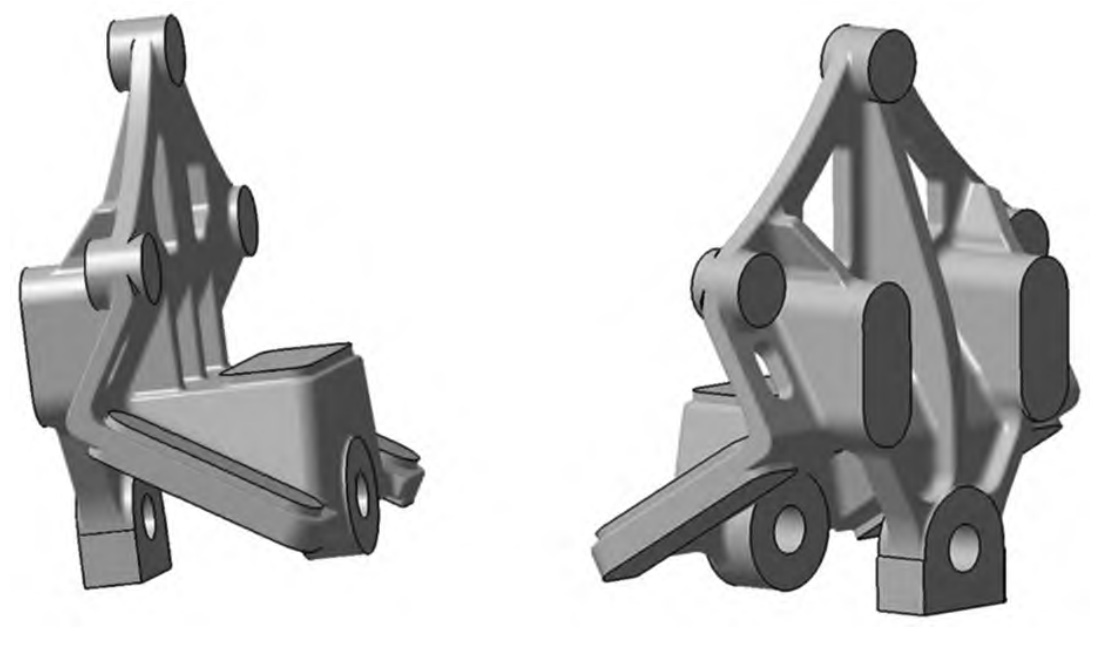

Internal shrinkage is one of the common casting defects in the production process of steel castings. Shrinkage cavities are mostly distributed in the upper part of steel castings or in the final solidification areas such as thick hot spots on the cross-section, at the grain boundaries and within the dendrites of dendrites. The solution to eliminate defects is to adopt various process measures to promote the solidification of steel castings in a certain order, and to try to timely obtain alloy liquid to supplement the shrinkage of the castings. Taking a recent steel casting produced by ZHY Casting as an example, this paper discusses the method of solving internal shrinkage cavities in support steel castings.

Shrinkage and porosity defects are common in steel castings. Understanding the high shrinkage rate of steel castings, carefully considering shrinkage, mastering the solidification sequence, and taking corresponding process measures based on specific products and parts can eliminate or minimize unwanted defects.