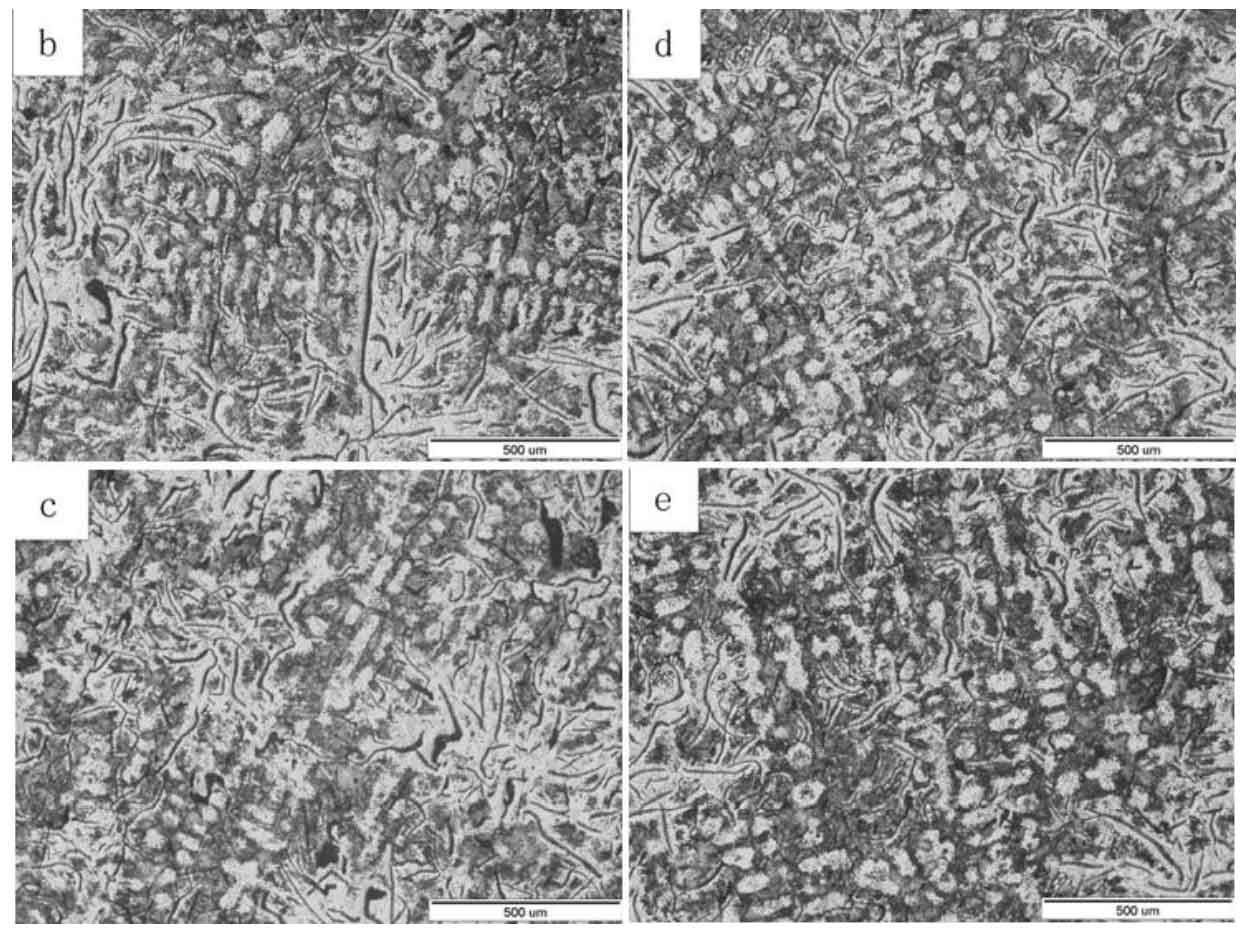

The microstructure of primary austenite after heat treatment of four kinds of experimental gray cast iron is shown in the figure, and the heat treatment process is the same. Compared with B and D in the figure, it is found that although primary austenite is formed in samples B and D, the primary austenite network framework structure of sample D is more complex; It can also be found that 0.25wt.% is added by comparing C and E in the figure The spatial network structure of primary austenite in E sample of alloy element Mo is more complex.

(d) the gray cast iron D added 0.25wt.% alloying elements Mo and by 0.8wt.%JF-1+SiFe compound modification;

(c) the gray cast iron C by 1.0wt.%JF-1+SiFe compound modification;

(e) the gray cast iron E added 0.25wt.% alloying elements Mo and by 1.0wt.%JF-1+SiFe compound modification.

That is, the addition of Mo will be more conducive to the formation of complex spatial network structure of primary austenite. The main reason is that Mo can not only significantly increase the undercooling of Eutectic Transformation, so as to expand the range of crystal growth temperature and increase the amount of dendrite precipitation, but also show positive segregation in austenite, and the component supercooling zone formed by Mo enrichment appears in the liquid phase before solidification interface, Component undercooling leads to the full development of austenite secondary dendrites, the resulting dendrites are refined, more branches, and the dendrite arm spacing is reduced accordingly. Austenite dendrites may collide and intersect with each other, thus forming a more complex spatial network structure. The complex spatial network structure of primary austenite will limit the space of eutectic reaction, reduce the size and increase the number of eutectic clusters.