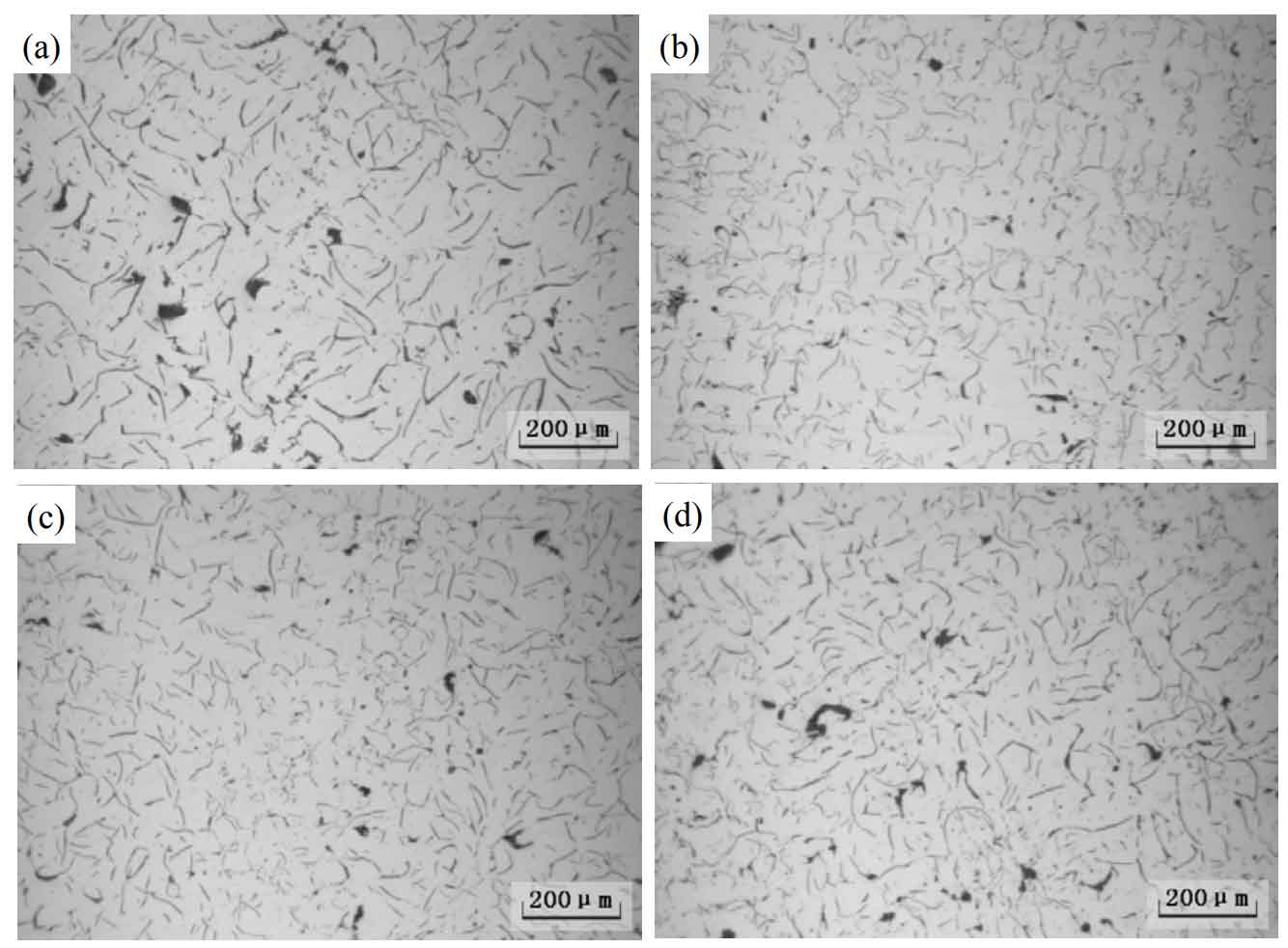

Due to the existence of graphite in common gray cast iron, and the tensile strength of graphite is almost zero, gray cast iron can be regarded as steel full of cracks or cavities. Graphite not only destroys the continuity of the matrix, reduces the effective cross-sectional area of the metal matrix under load, and greatly increases the actual stress; At the same time, it is easy to cause stress concentration at the sharp corner of graphite, so that the stress at the sharp corner is much greater than the average stress. The greater the number, size and uneven distribution of graphite flakes in gray cast iron, the greater the impact on mechanical properties. The graphite morphology photos of the four groups of samples are shown in Figure 1.

It can be observed from Figure 1 that the graphite in the matrix of the four groups of samples is mainly type a graphite, and a small amount of type D graphite appears. Type a graphite sheet has small size, uniform distribution and no directionality. It is the most common graphite form. The mechanical properties of gray cast iron with this graphite form are the best. Other types of graphite will reduce the mechanical properties of gray cast iron to varying degrees. In the photo, it can be observed that the graphite of samples 2, 3 and 4 is finer and more uniform than that of sample 1 without alloy element addition. The addition of alloy elements Cu and Cr is conducive to the refinement of graphite. When gray cast iron is cut by high-speed rotating tool, fine and uniform graphite structure can improve the deformation of chip, reduce the friction force and wear area of tool, and improve the cutting life of tool.

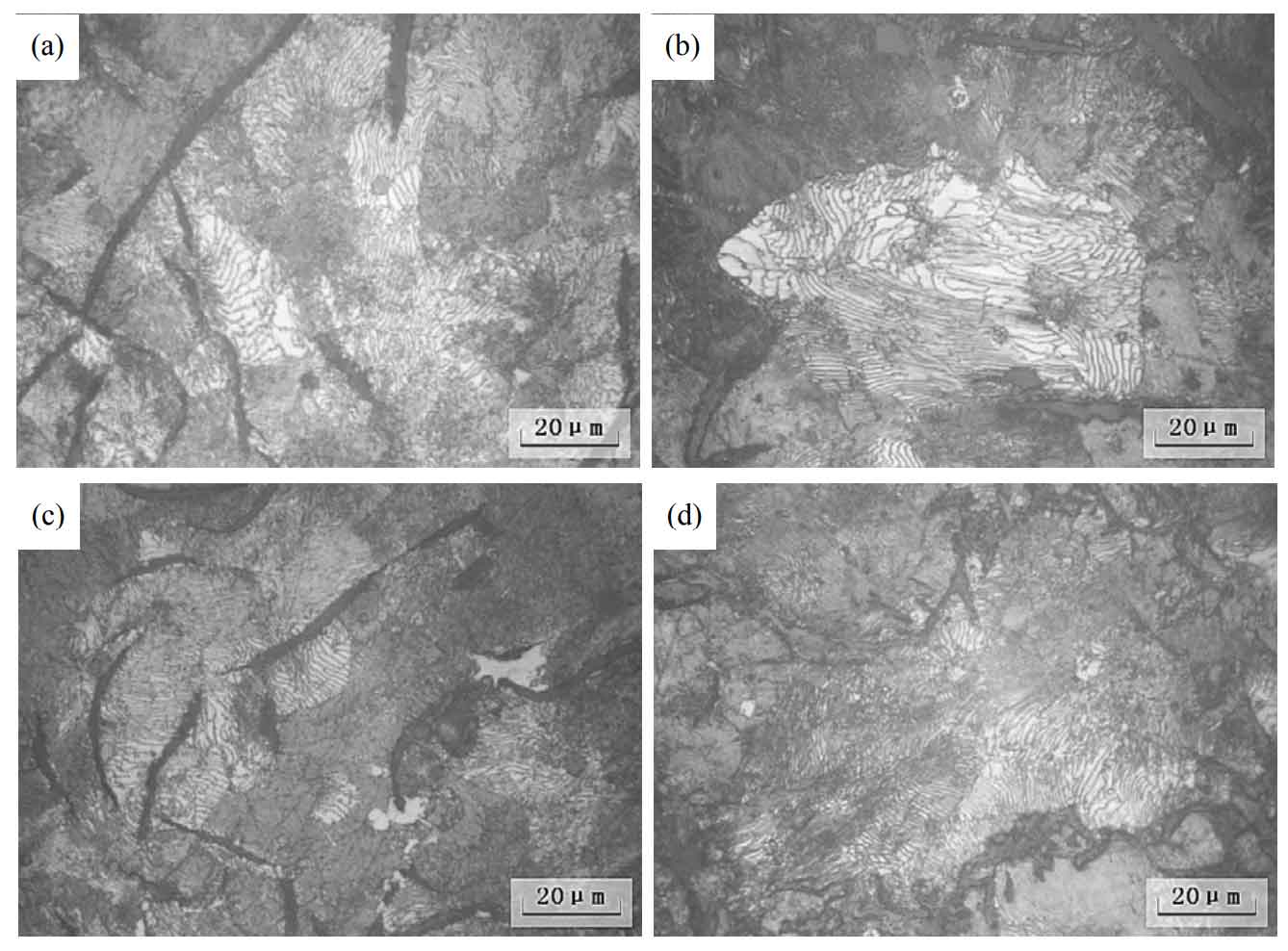

Fig. 2 is a photograph of the matrix structure of four groups of gray cast iron. It can be seen from the figure that the matrix structure of gray cast iron is pearlite matrix. The flake spacing, lamellar structure and carbide size of gray cast iron pearlite with different addition treatments are different. The pearlite flake spacing of sample 2 is larger than that of copper chromium composite addition. Specimen No. 4 has the smallest piece spacing. The composite addition of Cu and Cr can refine pearlite in a certain range, reduce the pearlite sheet spacing and increase the hardness and strength of the sample.