When studying the effect of carbon content on the thermal fatigue performance of laser bionic gray cast iron, the graphite type of the experimental material is controlled in the range of type a graphite with better performance. The effect of carbon content on the thermal fatigue performance is studied by changing the carbon content. The difference of nearly 0.6% carbon content is enough to make the thermal fatigue performance of gray cast iron appear obvious law.

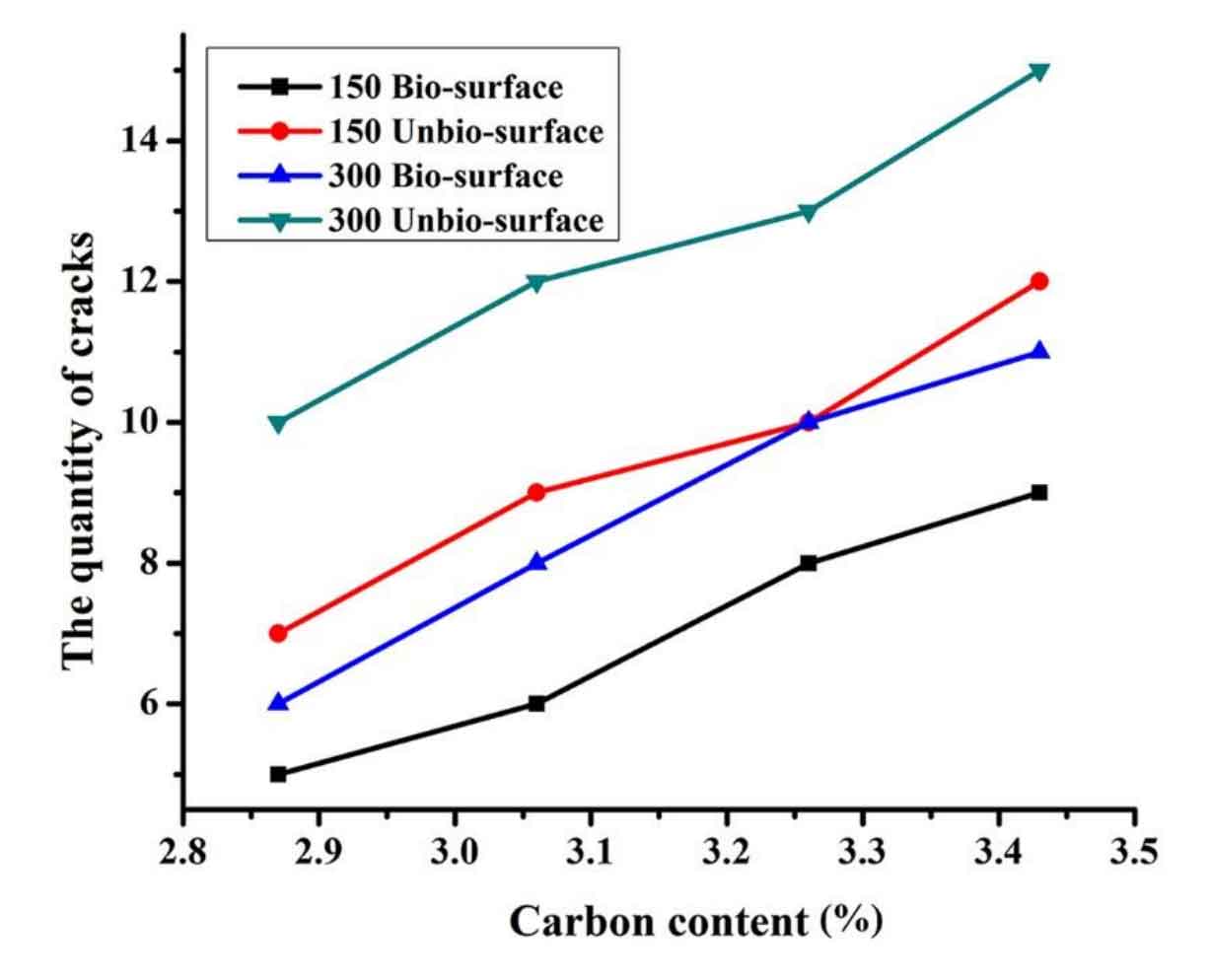

With the increase of carbon content, the quantity and size of graphite in gray cast iron increase to a certain extent, which directly affects the thermal fatigue properties of gray cast iron. As shown in Figure 1, with the increase of carbon content, the number of thermal fatigue cracks increases gradually on both bionic gray cast iron surface and blank gray cast iron surface. This is closely related to the amount of graphite in gray cast iron. When the amount and length of graphite in gray cast iron increase, it is equivalent to more and more hole defects in the matrix. In the process of thermal cycle, the thermal stress concentrates at the tip of graphite and induces microcracks in the material. The increase of graphite increases the number of microcracks and promotes the bridging of microcracks. Therefore, with the increase of carbon content, the number of thermal fatigue cracks increases gradually. However, for thermal fatigue crack growth, the situation is not the same as the growth of crack number. As we all know, graphite has much better thermal conductivity than gray cast iron matrix.

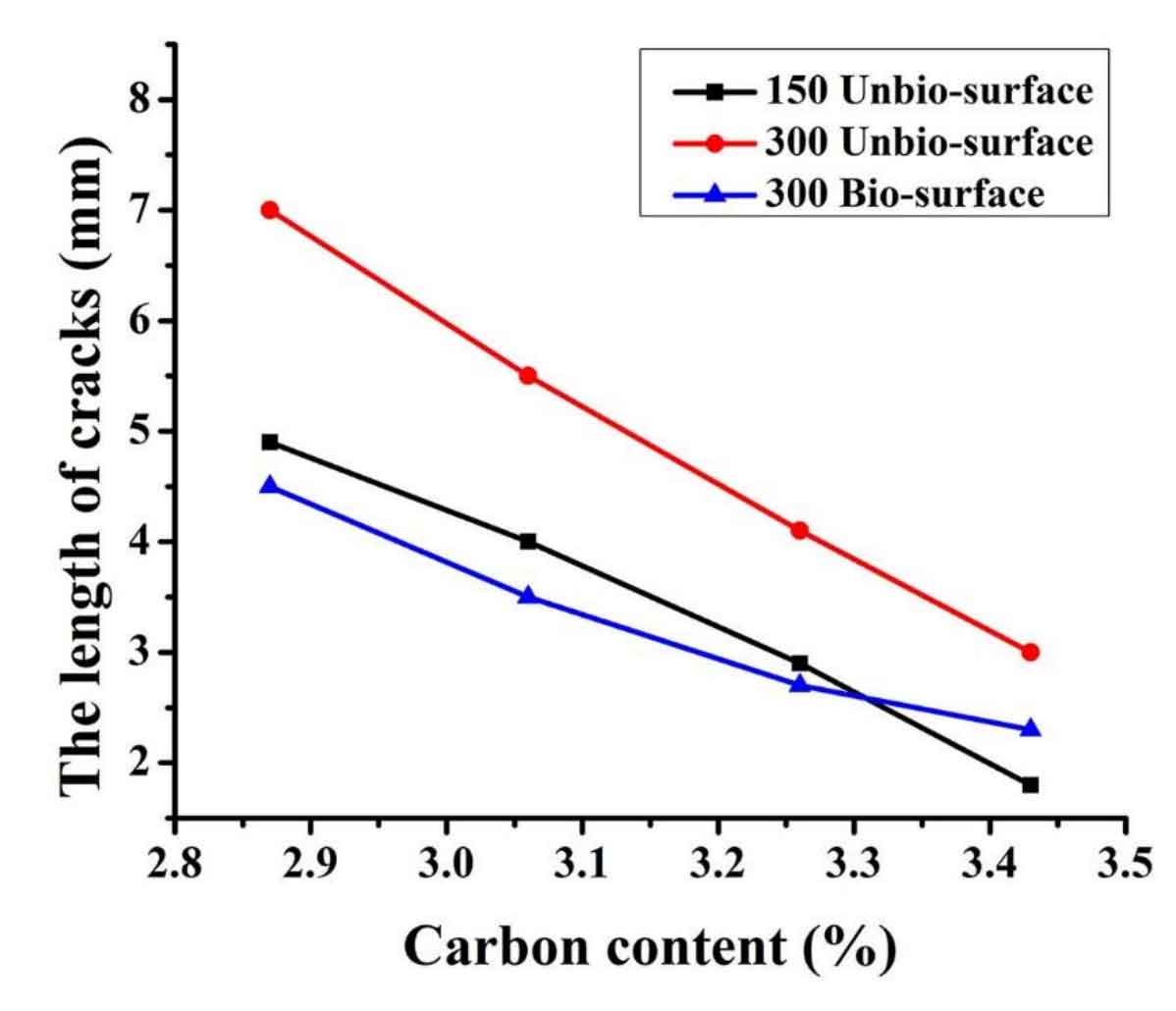

Therefore, with the increase of carbon content, the thermal conductivity of gray cast iron is becoming stronger and stronger. The excellent thermal conductivity reduces the temperature gradient and the corresponding internal stress during the thermal cycle of the sample. When the thermal fatigue crack growth no longer depends on the length and size of graphite (because the thermal fatigue crack is much larger and the stress is more concentrated than that of graphite at this time), the faster the crack growth speed of gray cast iron with slightly poor thermal conductivity (low carbon content), the longer the crack (as shown in Figure 2).

In addition to the influence of carbon content on the thermal fatigue properties of gray cast iron, the number of thermal cycles and whether there are bionic units also affect the thermal fatigue properties of gray cast iron. The analysis is as follows: with the increase of the number of thermal cycles, the hardness decreases due to the decomposition of cementite in the sample, and the resistance to crack propagation in gray cast iron decreases, making the crack easier to expand. Thermal cycle promotes the oxidation of gray cast iron, and the oxidation of material will promote the propagation of microcrack. Therefore, with the increase of the number of thermal cycles, the thermal fatigue resistance of gray cast iron becomes worse and worse. As shown in Figures 1 and 2, the number and length of cracks gradually increase with the increase of the number of thermal cycles. When gray cast iron contains Laser Biomimetic unit, its thermal fatigue resistance will be significantly enhanced.

With the increase of carbon content, the unit hardness of gray cast iron increases continuously, and the blocking effect on thermal fatigue cracks is more and more obvious at the beginning of thermal cycle. Therefore, the growth of thermal fatigue cracks on the surface of bionic gray cast iron tends to slow down during thermal cycle. In the later stage of thermal cycle, because the brittleness of the unit with high hardness also increases correspondingly, it is easy to crack due to thermal stress. However, the cracking of the unit body can effectively release the surface stress and reduce the generation of thermal fatigue cracks in the matrix. At the same time, it can also change the direction of crack propagation and prolong the time required for crack propagation. When the carbon content is low, the unit body is not easy to crack in the process of thermal cycle. Compared with the bionic unit of gray cast iron with high carbon content, it has better crack arrest effect.