The thermal fatigue resistance of materials is closely related to the tensile strength. Figure 1 shows the fracture morphology of the sample before thermal fatigue.

It can be seen from 1 (a) that the fracture mode of gray cast iron is brittle fracture, with smooth section in graphite area, while there are cleavage lines in pearlite area, which is cleavage fracture. It can be seen from figure (a) that pearlite can improve the tensile strength of the material, while graphite reduces the strength of the material.

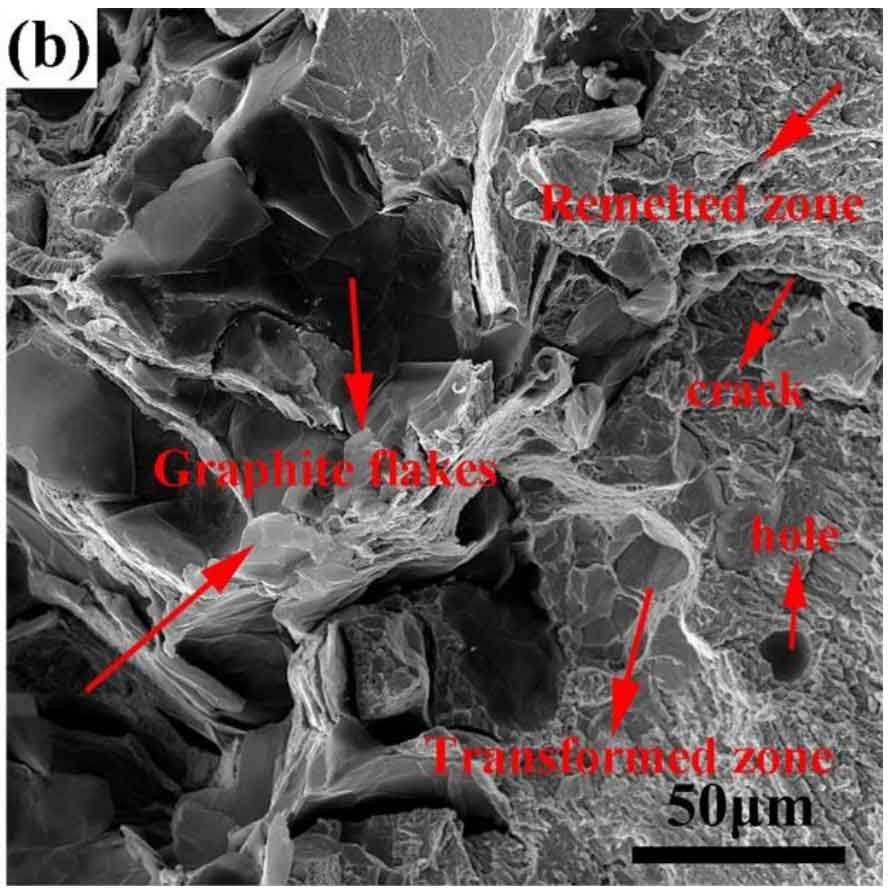

Figure 1 (b) shows the fracture morphology of matrix, unit and heat affected zone in bionic gray cast iron. It can be seen from the figure that the grains in heat affected zone have been refined, but there are also a few cracks and pores caused by laser processing near the heat affected zone.

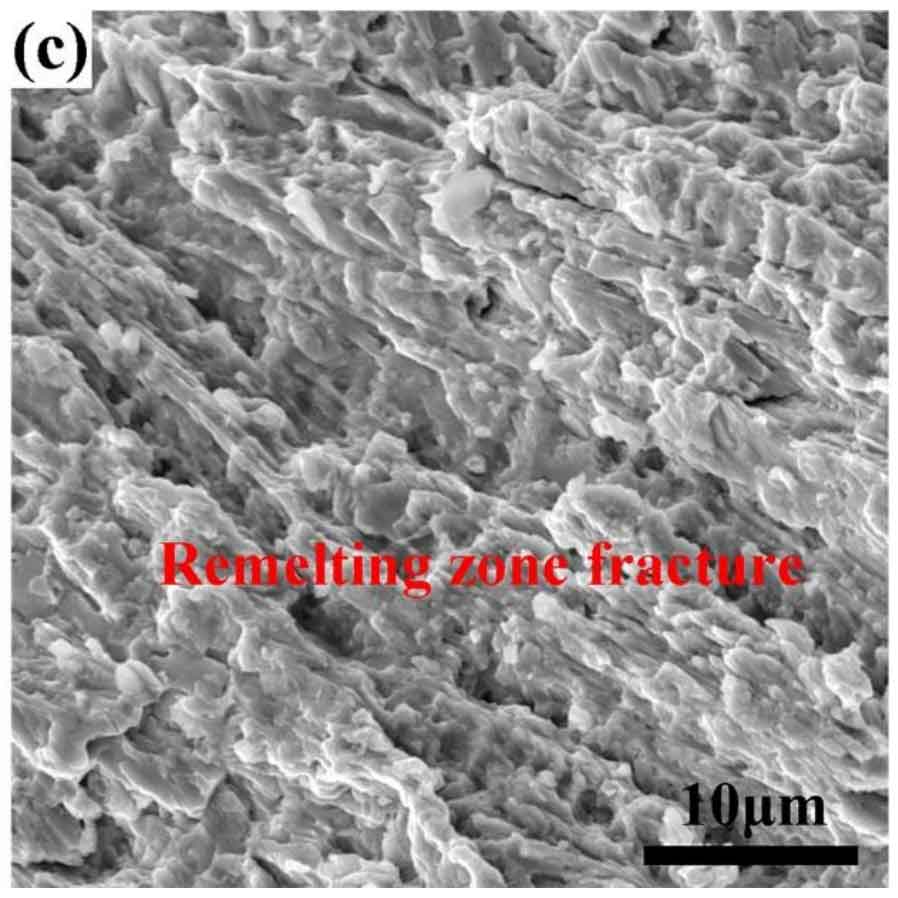

Fig. 1 (c) is an enlarged view of the fracture of the unit body. It can be seen from the figure that there are no brittle phases such as graphite in the unit body due to laser processing. Although it is the same brittle fracture as the gray cast iron matrix, the tensile strength is significantly improved due to the refinement of grains in the unit body area.

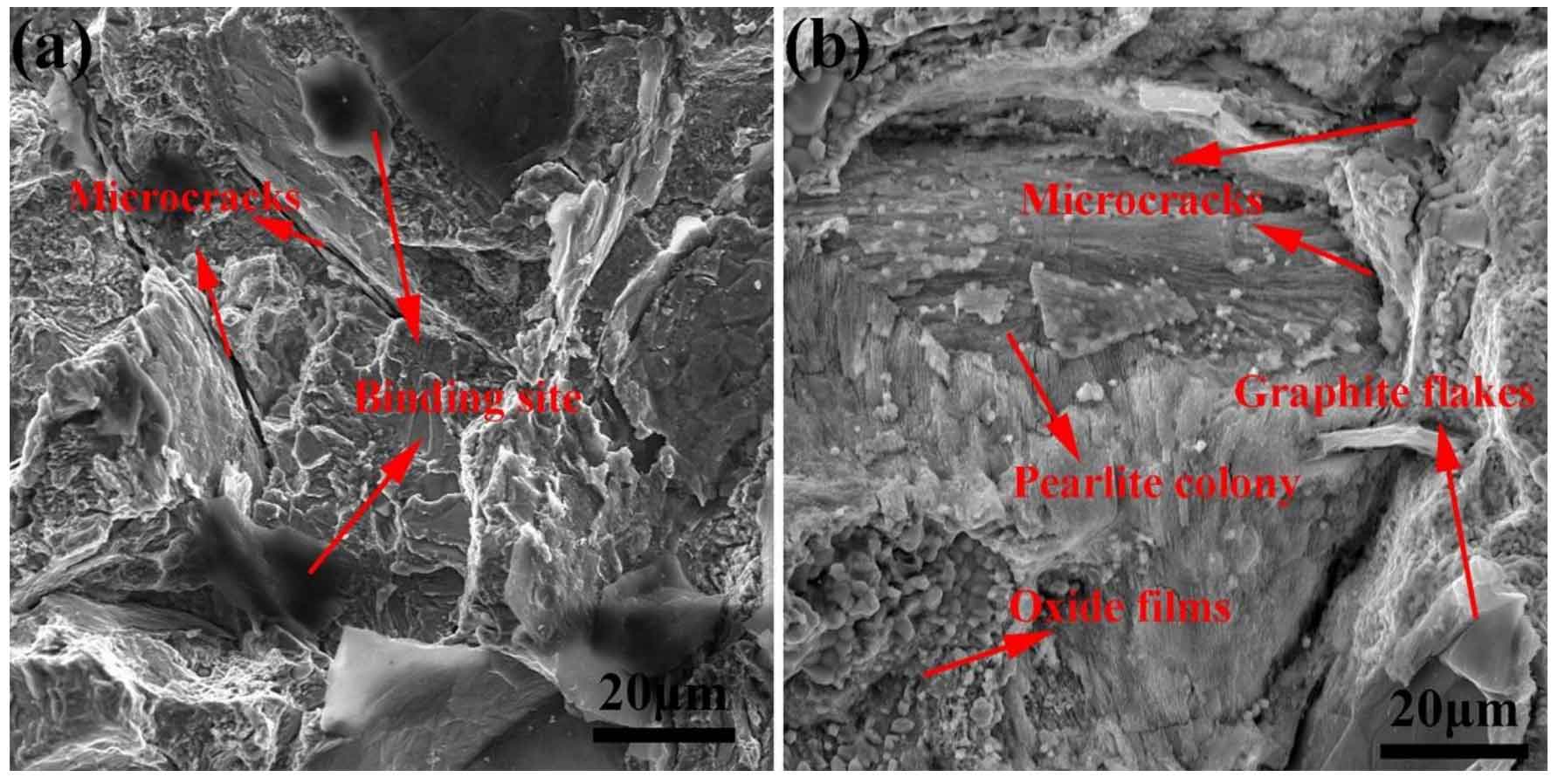

Figure 2 shows the microstructure of the thermal fatigue crack area. From figure (a), it can be seen that the fatigue fracture area is in a river pattern, the phase interface between graphite and pearlite is not closely combined, and cracks appear in the process of thermal cycle, while the pearlite content decreases or disappears and the strength is very low in the bonding area around the crack due to phase transformation, decarburization and other reasons in the process of thermal cycle; Figure (b) further verifies that the thermal fatigue crack cracks along the soft phases such as the grain boundary of graphite and pearlite group or the area with loose bonding, while the thermal fatigue destroys the bonding bond of each phase in gray cast iron. It can also be seen from the figure that many layers of flake pearlite fall off, and at the same time, there are a large number of oxide films at the crack, which will promote the initiation and propagation of cracks and reduce the thermal fatigue resistance of the material.