Gray cast iron cylinder head pig iron is added according to 5%, 10%, 15% and 20% of the total charge.

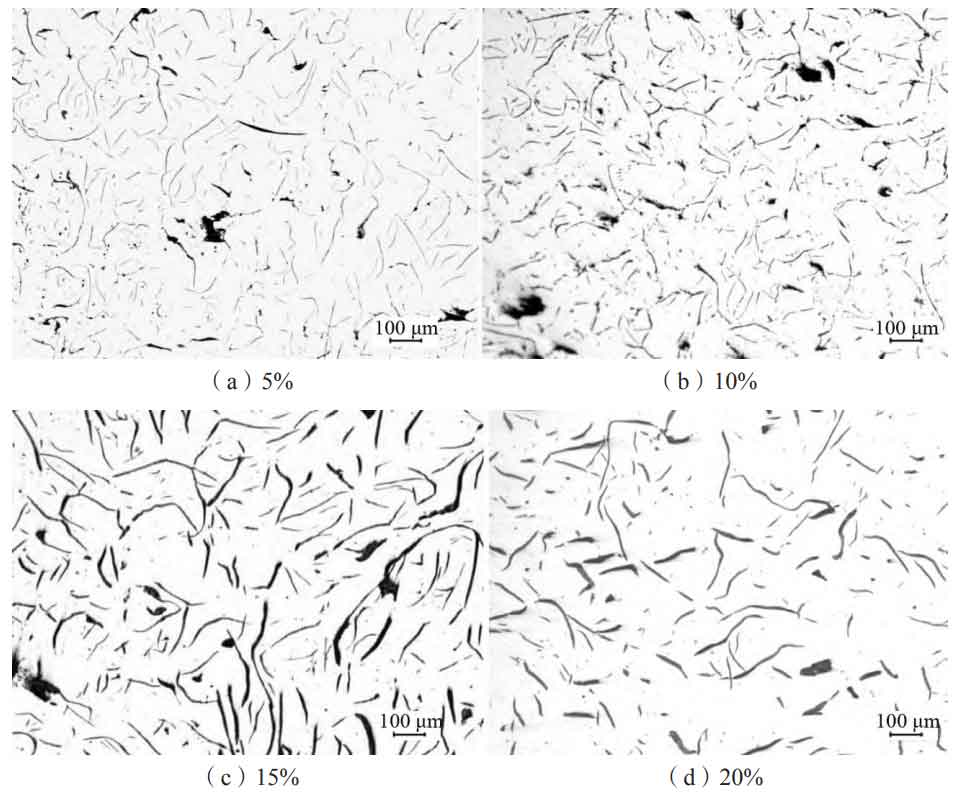

The inspection results of the products produced by the two test schemes are shown in the table. The figure shows the graphite morphology with different pig iron addition. It can be seen from table and figure that the effects of different pig iron addition on gray cast iron cylinder head are as follows.

| Serial number | Pig iron addition /% | Graphite type | Pearlite content /% | Average surface hardness HB | Tensile strength / MPa |

| 1 | 5 | Type A | 95 | 210 | 279 |

| 2 | 10 | Type A | 95 | 205 | 263 |

| 3 | 15 | Type A | 95 | 193 | 248 |

| 4 | 20 | Type A | 95 | 187 | 235 |

(1) Metallographic changes. ① The matrix structure changes little in different test schemes, and the pearlite content is ≥ 95%; ② With the increase of pig iron addition, the length of graphite obviously becomes longer, and the length of graphite increases from Grade 5-6 to about grade 3-4. Figures a and B are shorter than C and 5D graphite; ③ With the increase of pig iron addition, the number of graphite decreases significantly. The number of graphite in figures a and B is significantly more than that in figures C and D.

(2) Influence of body surface hardness. With the increase of pig iron addition, the surface hardness decreases gradually.

(3) Effect of tensile strength. With the increase of pig iron addition, the tensile strength decreases gradually.

Cast pig iron has good casting performance and low price. It is generally the necessary charge for smelting gray cast iron cylinder head. However, pig iron is subject to the influence of raw ore. The content of impurity elements in raw ore from different producing areas is different, so the addition amount of pig iron will be controlled within 30%. However, due to the genetic influence of the charge, the coarse graphite flakes in the pig iron cannot be eliminated after smelting, and remain from the liquid state to the solid state, resulting in a large amount of coarse graphite in the nucleation of the cylinder head of gray cast iron. The reason is that although the pig iron is remelted, the melting point of the graphite is above 2000 ℃, and the graphite cannot be completely melted in the remelting process. These unmelted graphite are mixed with carbon With the growth of graphite and graphite, the content of carbon and silicon in the graphite matrix will be continuously reduced. Therefore, the graphite and graphite will become crystalline in the process of growing up, and the strength will be reduced, The existence of coarse graphite bonding sheet weakens the strength of the matrix. With the increase of cast pig iron, the tensile strength and hardness of gray cast iron cylinder head decrease significantly. When the amount of pig iron is ≥ 30%, the tensile strength is very low.