Under normal circumstances, the number of graphite balls in nodular cast iron will affect the matrix structure and stress distribution of nodular cast iron, which will have an important impact on its mechanical properties. The more the number of graphite balls per unit area, the greater the elongation of nodular cast iron and the lower the tensile strength.

From the number of graphite balls in the vibration lost foam casting nodular cast iron, the number of graphite balls in the unit area of the nodular cast iron prepared at 100Hz is the most, while the number of graphite balls in the unit area of the lost foam casting nodular cast iron without vibration is the least. According to the existing research results, the less the number of graphite balls per unit area, the higher the tensile strength of nodular cast iron. However, the research results show that the properties of EPC nodular cast iron without vibration are lower than those of nodular cast iron prepared at 35Hz, which may be related to the decrease of spheroidization rate caused by graphite distortion in EPC nodular graphite without vibration. In addition, the tensile strength of spheroidal graphite cast iron prepared at vibration frequencies of 50Hz and 100Hz is lower than that of spheroidal graphite cast iron without vibration. The main reason may be related to the increase in the number of graphite balls per unit area in the vibration lost foam casting spheroidal graphite cast iron.

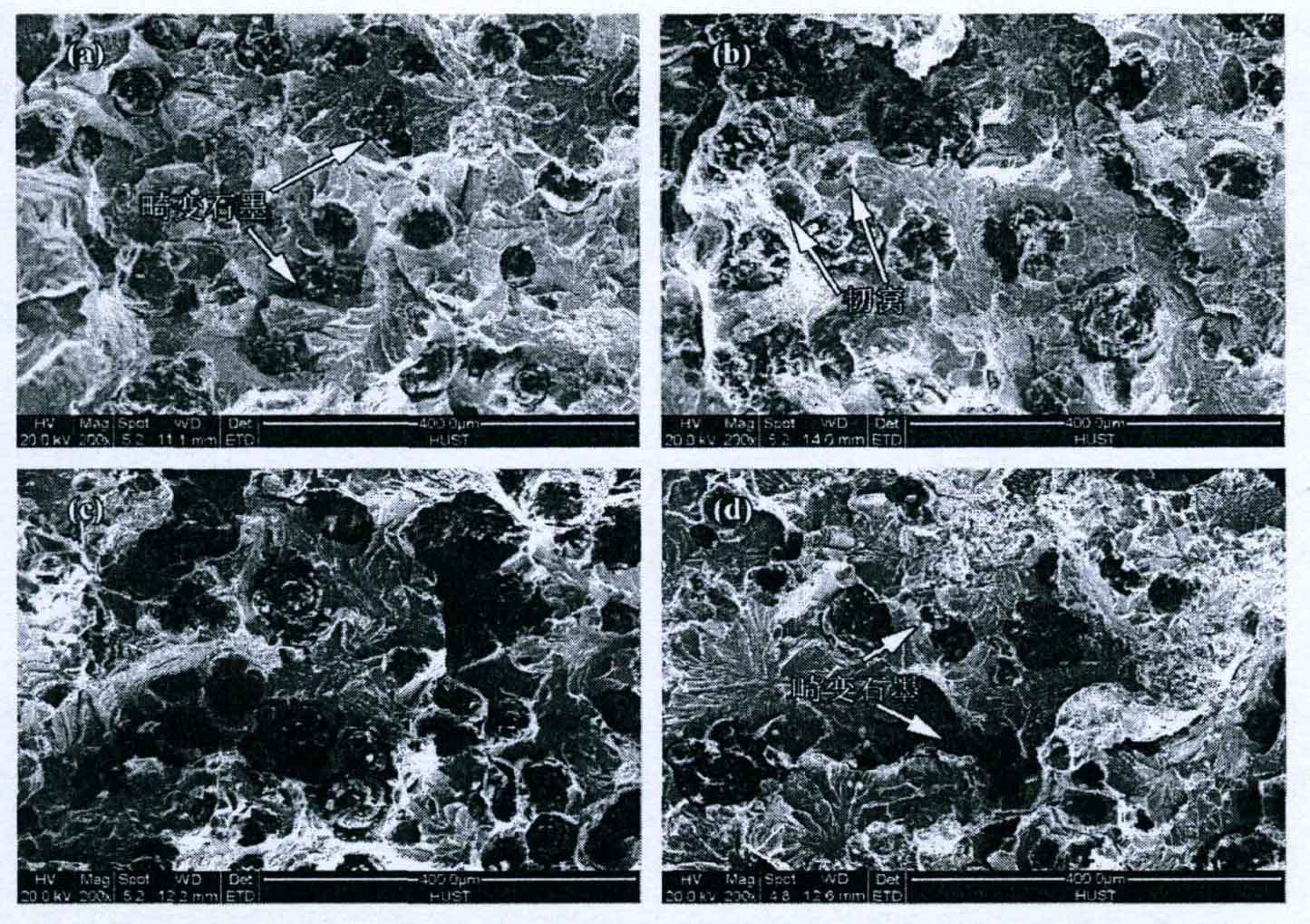

In order to analyze the fracture mechanism of nodular cast iron, the fracture morphology of nodular cast iron was observed by scanning electron microscope. The results are shown in the figure. Among them, figures (a) – (d) show the fracture morphology of nodular cast iron prepared under the vibration frequency of 0, 35, 50 and 100Hz respectively.

It can be seen from the figure that the fracture surface of both vibrated EPC nodular cast iron and EPC nodular cast iron without vibration presents the cleavage fracture mechanism of river pattern.

In addition, it can be seen from the fracture morphology that the graphite size in the EPC nodular cast iron without vibration and the spacing between the graphite ball and the spalling edge are small, and there are more distorted graphite on the fracture, as shown by the arrow in figure (a), which can be inferred that the ductile cast iron produced by this process has a low plasticity; However, the existence of deformed graphite in the lost foam casting nodular graphite Z cast iron without vibration will cause stress concentration in the cast iron, increase the cleavage effect of graphite on the body of nodular cast iron, reduce the utilization rate of cast iron matrix strength, and thus reduce the tensile strength and shape of cast iron. Although the fracture morphology of nodular cast iron prepared at the vibration frequency of 35Hz is still the cleavage fracture mechanism of river pattern, there are a small number of dimples on the fracture (as shown by the arrow in Figure b), and the distance between the graphite ball and the tearing edge is large, and the graphite size and distribution are uniform. These characteristic structures will hinder the deformation of cast iron alloy, Improve its tensile strength and elongation. When the vibration frequency increases to 50Hz and 100Hz, although the distance between the graphite ball and the tearing edge in nodular cast iron is still large, the graphite in nodular cast iron becomes serious, and the graphite size and distribution are uneven, which reduces the performance of nodular cast iron. Therefore, the tensile strength and elongation of nodular cast iron prepared at the vibration frequency of 50Hz and 100Hz are low.