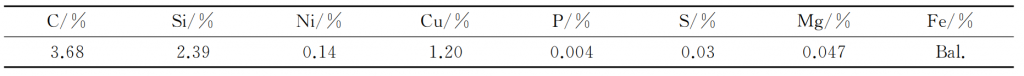

The test sample bar is taken from the cylindrical nodular cast iron test bar melted in the medium frequency induction furnace. The size is Φ 40mm × 150mm, and its chemical composition is shown in Table 1.

Use Hefei kejing ksl-1200 box type heat treatment furnace for normalizing treatment, heat it at 10 ℃ / min, and then heat it at 870 ℃, 900 ℃ and 930 ℃ respectively for 1h, then cool it to 727 ℃ with the furnace, and finally take out the air to cool it to room temperature. Use a wire cutting machine to cut 10mm from the as cast and normalized round test bar of nodular cast iron × 10mm × The metallographic sample was made of 30mm small sample block, and the microstructure of the sample was observed by Kearns vh-5000 ultra depth of field optical microscope. Process the specimen to a wide × 12.5mm high × The tensile specimen with 3mm and gauge distance of 34.6mm was used to measure the mechanical properties of the specimen at room temperature with an electronic universal testing machine, and the tensile was carried out at a strain rate of 2mm / min at room temperature. Take the average value of the test results of two tensile samples for the elongation and tensile strength of nodular cast iron. Hitachi s-4800 scanning electron microscope was used to observe the fracture morphology and side tensile crack of the sample.