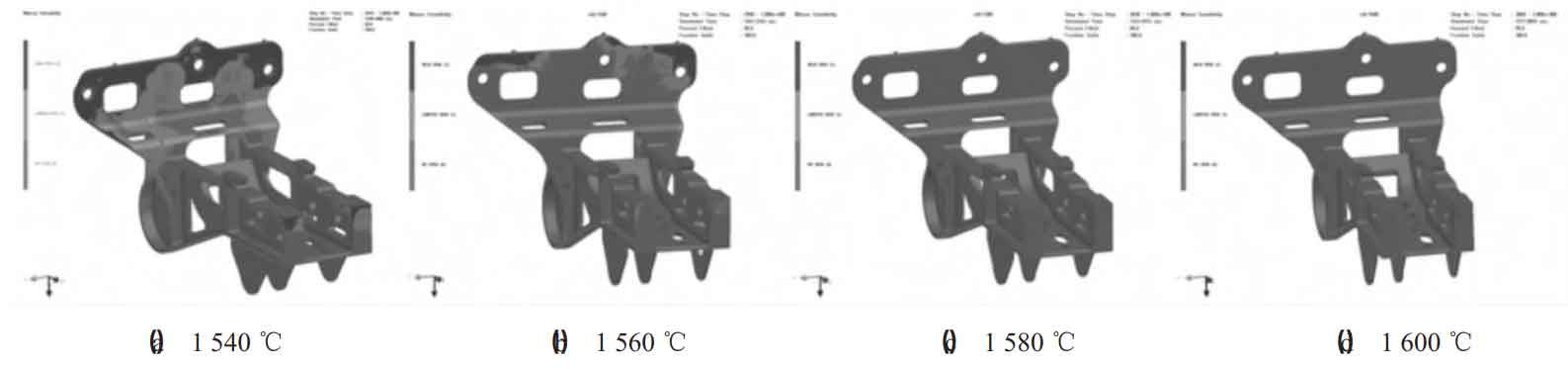

In the casting defect scheme, the actual pouring temperature is 1560 ℃, and the actual average pouring speed is 0.38 M / S. in order to determine the reasonable range of pouring temperature corresponding to the actual average pouring speed (without cold lap casting defects), according to the principle of control variable method, the pouring speed is set to 0.38 M / s, and the pouring temperatures are respectively set to 1540 ℃, 1560 ℃, 1580 ℃ and 1600 ℃. Except the pouring temperature, other main parameter settings are the same as table 1, For the above casting defect products with insufficient pouring, the above schemes with different pouring temperatures are simulated by momentum decoupling analysis method, and the cold lap prediction results are shown in the figure.

According to the cold lap prediction results shown in the figure, it can be seen that without considering the influence of the gas model, under the condition of a certain pouring speed, the higher the pouring temperature, the smaller the tendency of insufficient cold lap pouring of investment casting steel castings. When the pouring temperature of this product is 1 540 ℃, there is a large area of insufficient pouring area at the filling end, the insufficient pouring area at 1 560 ℃ is basically consistent with the actual casting defects, and there is basically no risk of insufficient pouring of investment casting steel castings at 1 580 ℃, At 1 600 ℃, there is no risk of insufficient pouring of investment casting steel. According to the analysis results, it can be determined that under the actual average pouring speed, the reasonable pouring temperature of this product is more than 1580 ℃.