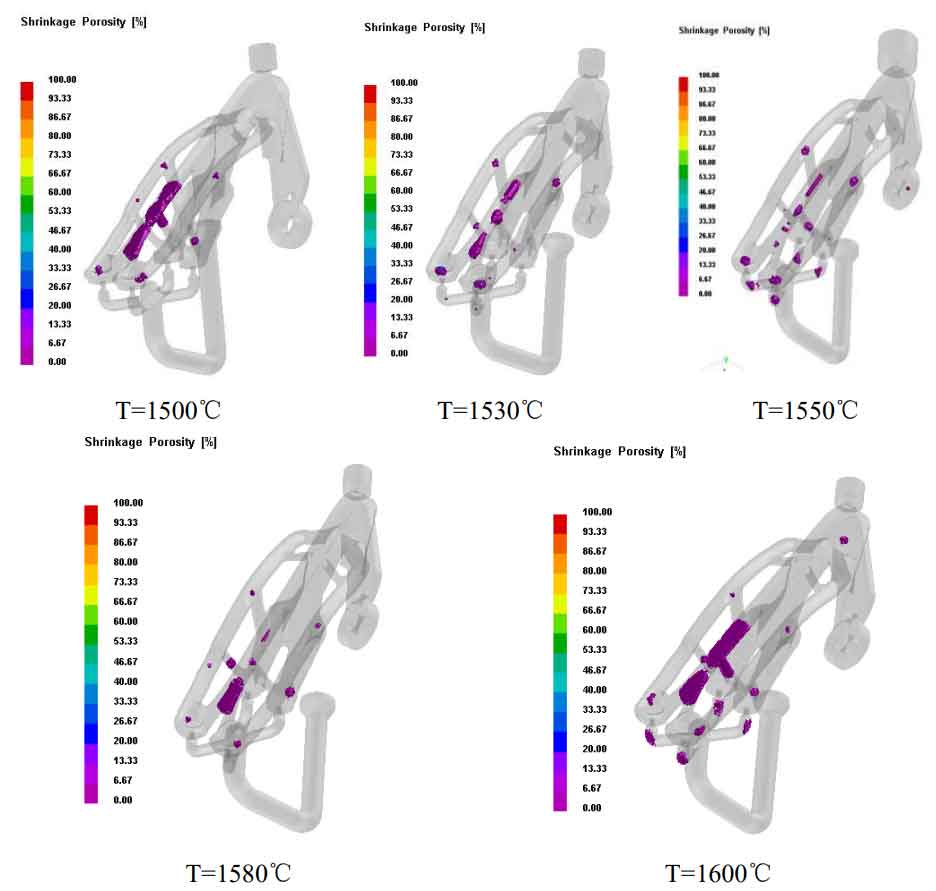

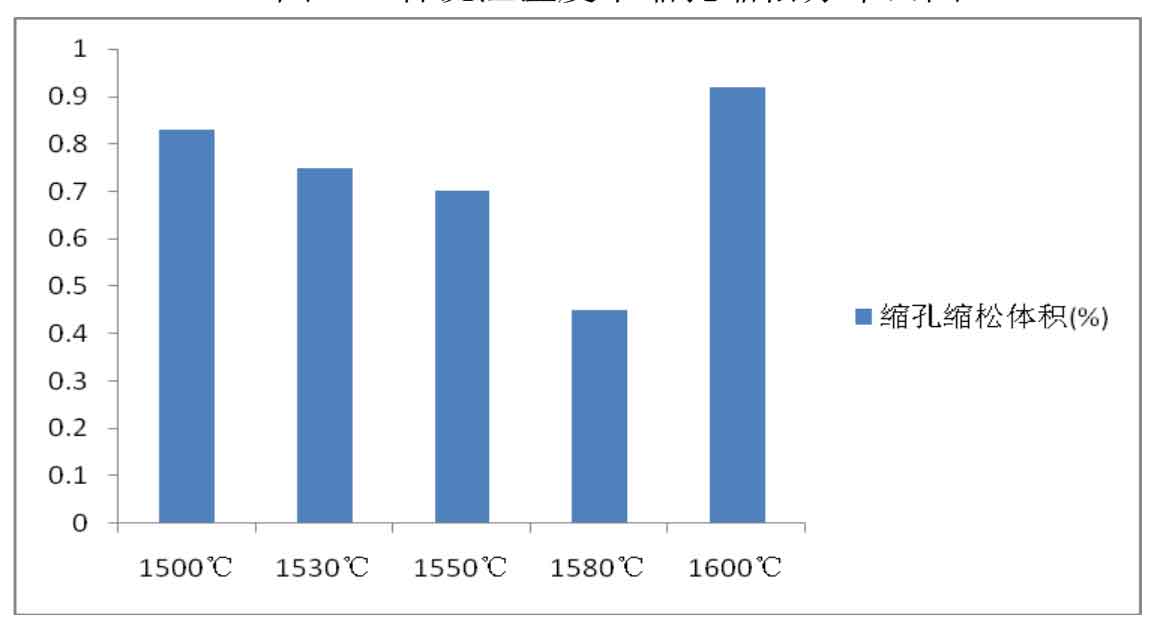

Parameter setting: when the pouring speed is 30mm / s and the shell preheating temperature is 600 ℃, the pouring temperatures are 1500 ℃, 1530 ℃, 1550 ℃, 1580 ℃ and 1600 ℃ respectively. Figure 1 shows the distribution cloud diagram of shrinkage cavity and porosity casting defects at various temperatures, and Figure 2 shows the volume fraction of shrinkage cavity and porosity casting defects at different pouring temperatures.

As shown in Figure 2, when the pouring temperature is 1550 ℃ and 1580 ℃, the casting defects are the least. When the pouring temperature is 1580 ℃, the minimum casting defect volume reaches 0.45%. When the pouring temperature is reduced, the defects increase obviously. When the pouring temperature is increased to 1600 ℃, the casting defects are the most obvious. It can be seen that the pouring temperature should be kept at 1580 ℃.