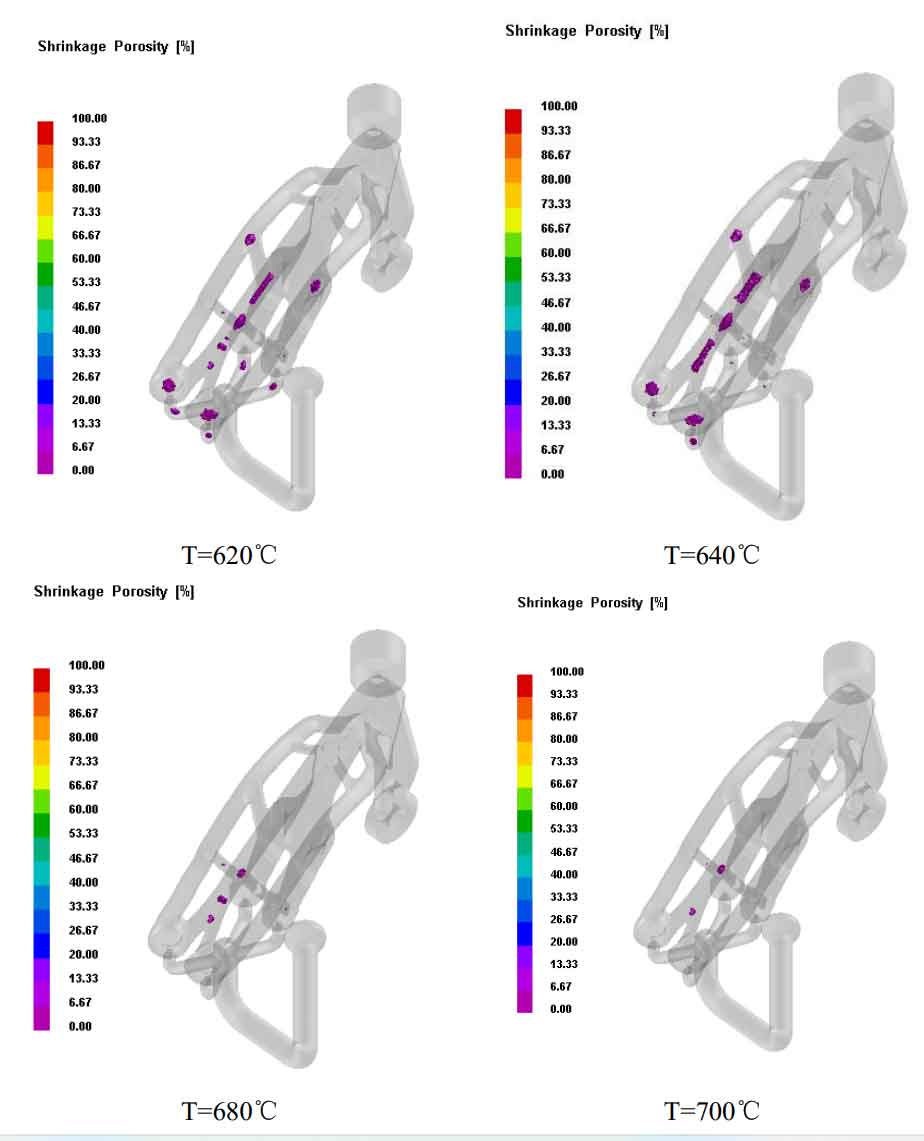

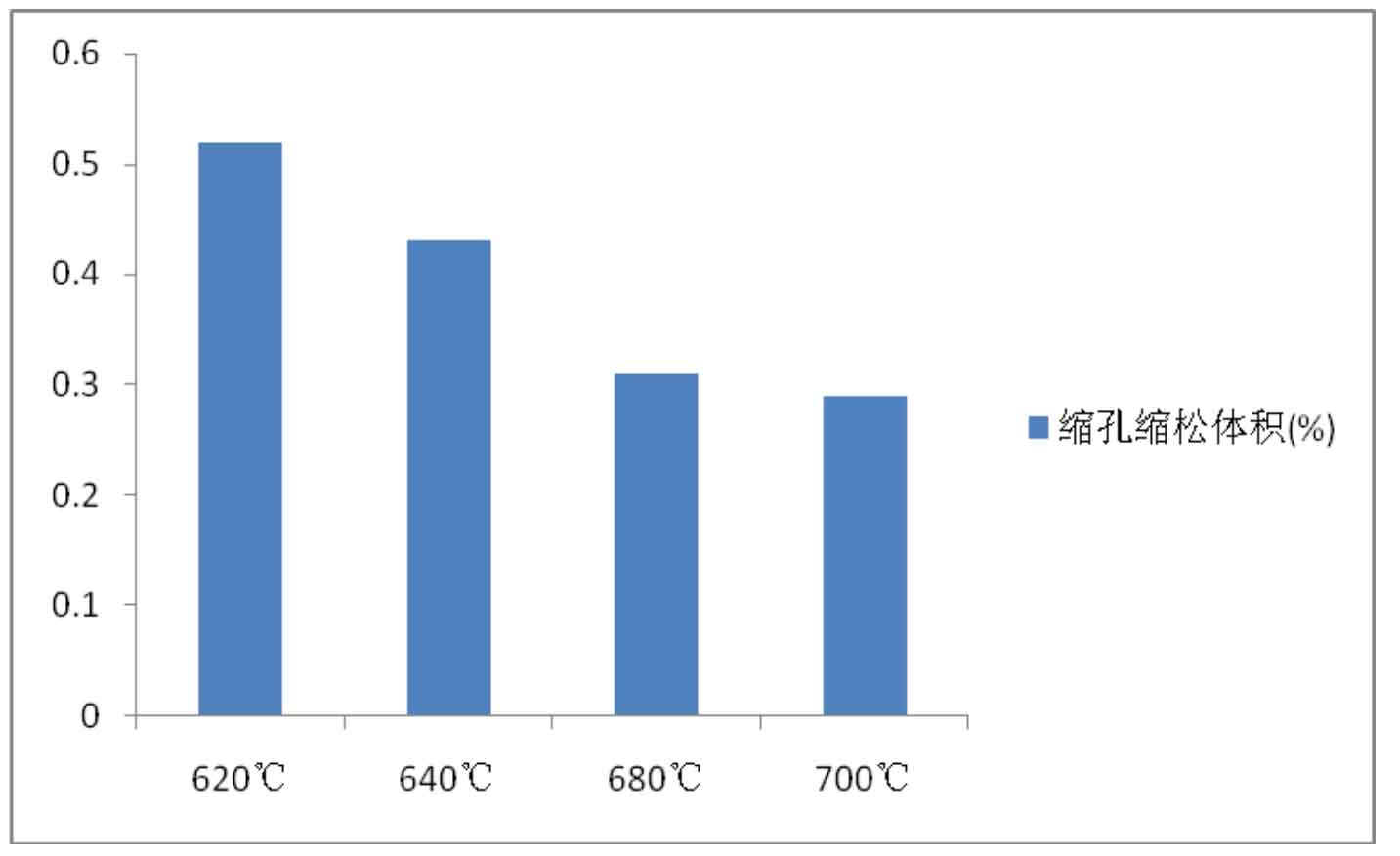

Parameter setting: when the pouring temperature is 1550 ℃ and the pouring speed is 30mm / s, the shell preheating temperatures are 620 ℃, 640 ℃, 680 ℃ and 700 ℃ respectively. Figure 1 shows the distribution cloud diagram of shrinkage cavity and porosity casting defects at each shell preheating temperature, and Figure 2 shows the volume fraction of shrinkage cavity and porosity casting defects at different shell preheating temperatures.

It is obvious from the distribution cloud diagram of shrinkage cavity casting defects that the volume of shrinkage cavity casting defects decreases gradually with the increase of mold shell preheating temperature. Therefore, under the condition of ensuring the high-temperature strength of mold shell, the preheating temperature of mold shell can be appropriately increased to improve its mold filling and feeding capacity.