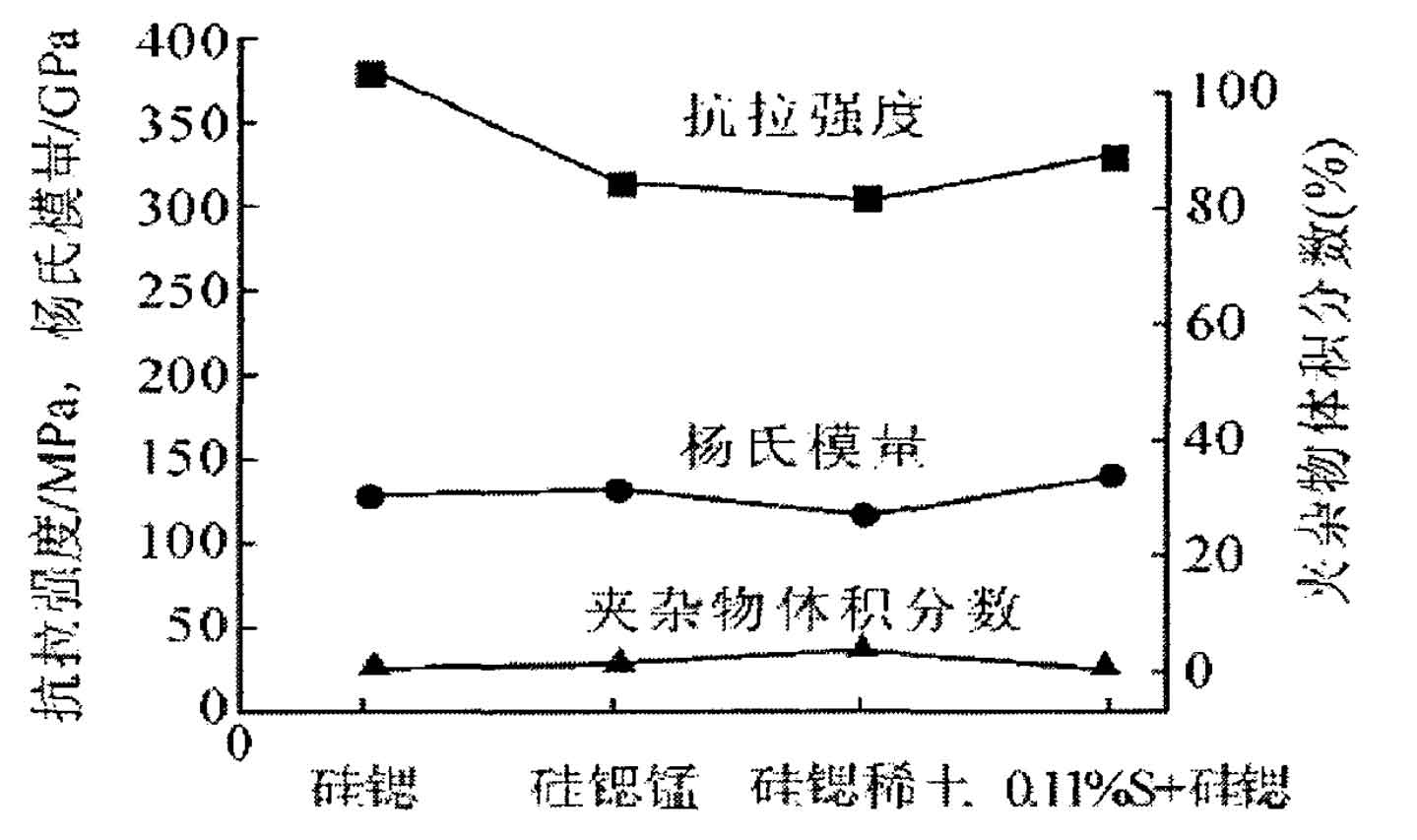

Oxygen mainly exists in the form of oxidation inclusions in gray cast iron. Gray cast iron samples with different oxidation inclusion contents are obtained by treating gray cast iron with different inoculants such as silicon strontium, silicon strontium manganese, silicon strontium rare earth and 0.11% s + silicon strontium. The relationship between oxidation inclusion and tensile strength and young’s modulus is measured, as shown in the figure, The amount of oxidation inclusions is inversely proportional to the tensile strength and Young’s modulus, that is, within a certain range, with the increase of the amount of oxidation inclusions, the tensile strength and Young’s modulus of gray cast iron become relatively small. On the contrary, with the decrease of the amount of oxidation inclusions, the tensile strength and Young’s modulus of gray cast iron become relatively large.

The application of rare earth in the inoculation process of gray cast iron can effectively reduce the influence of oxygen on the properties of gray cast iron. This is mainly because the strong affinity between rare earth and oxygen produces stable rare earth oxides in the casting process. One part leaves the molten iron in the slag raking process, and the other part exists in the molten iron as an external core, Promote graphitization, so as to refine grains and enhance the properties of gray cast iron.

Phosphorus will cause low temperature brittleness of iron carbon alloy and serious segregation of castings. However, increasing phosphorus content in a certain range can improve the fluidity of molten iron, increase the wear resistance and strength of gray cast iron, promote graphitization and reduce the tendency of white cast iron; Excessive phosphorus will increase the brittleness of gray cast iron. When the phosphorus content in the casting exceeds, phosphorus will exist in the grain boundary in the form of binary or ternary phosphorus eutectic. These fine dispersed phosphorus eutectic will lead to shrinkage porosity defects of the casting; In the process of inoculating gray cast iron with rare earth, only when the number of rare earth atoms remaining in the molten iron is the number of phosphorus atoms, the rare earth can react with the phosphorus element dissolved in the molten iron to form phosphorus compounds and reduce the brittleness of gray cast iron caused by phosphorus. It is found that rare earth has a significant effect on high phosphorus cast iron, Rare earth can be used as modifier to break the continuous network distribution of phosphorus eutectic and refine graphite and matrix. It is a brand of high phosphorus gray cast iron.