The lost foam casting products have the advantages of good surface quality, high dimensional accuracy, and high process yield, and are applied in the production of ductile iron. The gearbox housing requires high strength, toughness, wear resistance, and seismic performance, and is made of QT450-10 material. The weight of the gearbox housing casting is 112kg, with a wall thickness of 54mm at the thickest part and 14mm at the thinnest part. The geometric hot spot is concentrated. Based on the production capacity of the foundry equipment and the characteristics of the casting, the lost foam mold is selected Casting process.

The carbon content of ductile iron castings is generally 3.5% to 3.8%, which is prone to carbon defect inclusions. Considering both gas generation and carbon content, the white mold of ductile iron is selected with copolymer material. The copolymer material balances EPS and EP The gas generation and solid carbon content of MMA reduce the possibility of carbon defects in castings; Reduce the risk of porosity defects in castings. The reducer housing made of ductile iron material has inclusions on the end face and shrinkage holes at the geometric hot joint during mass production. Analysis of the causes of these two defects.

A large number of pyrolysis products, such as gaseous, liquid and solid products, will be produced during the thermal decomposition of the copolymer foam pattern used for forming in EPC. These products are affected by many factors in the transmission process. The state, composition and discharge form of pyrolysis products vary, which is the most fundamental reason for the formation of carbon defects in EPC.

From the perspective of carbon equivalent of ductile iron, since the mechanical properties of the Y-shaped specimen meet the requirements of QT450-10 and the spheroidization rate of 2-3 levels also meets the technical requirements of the ductile iron reducer housing, the chemical composition of the reducer housing is not adjusted; At the same time, from the observation of the surface quality of the ductile iron reducer housing, there is no cold insulation or sand sticking problem, and the factors affecting the shrinkage of the reducer housing caused by the spheroidization treatment temperature and pouring temperature are excluded; The fundamental reason for the formation of shrinkage holes in ductile iron castings is that during liquid shrinkage and solidification of the alloy, a certain part of the casting (usually the final solidified hot spot) cannot receive timely replenishment of liquid metal, resulting in irregularly shaped holes with rough walls. The solution to the shrinkage of the gearbox housing mainly starts with casting process measures.

The inclusions in the gearbox housing are related to the characteristics of the lost foam casting process and cannot be completely eliminated. Only process methods can be used to solve the inclusion defects. According to the inclusions in the gearbox housing and actual processing conditions, the majority of inclusions in the gearbox housing castings also appear on the upper end face of the castings. Experiments were conducted to determine the depth of inclusions, and the results showed that the depth of inclusions on the end face of the gearbox housing was not greater than 8mm. According to the test results, an additional 4mm margin is added to the original margin of the reducer housing, resulting in a final end face design with a process margin of 8mm. Validate through mass production and perform statistical analysis on the machining data of the gearbox housing. The finished product rate of the gearbox housing casting before improvement was 88%, and after improvement, the finished product rate of the gearbox housing processing increased to 97.96%, indicating that increasing the surplus of the gearbox housing process can effectively solve the inclusion defects on the end face of the gearbox housing.

There are two traditional solutions for shrinkage defects in castings. One is to set up a riser at the hot junction to provide metal liquid that needs to be compensated for volume changes during the casting forming process, eliminating shrinkage; The second is to use rapid cooling The most commonly used system is to use cold iron to form a human end zone at the hot junction, which can transform the middle zone, which originally had almost no temperature difference, into a rapidly cooled zone with a larger temperature difference, forming a sequential solidification and eliminating shrinkage defects. Although both methods can solve shrinkage and porosity defects, they are not suitable for lost foam casting of gearbox housings. Adding risers reduces the production rate of gearbox housing castings and increases the overall process difficulty. The process of using cold iron, due to the characteristics of lost foam casting, is prone to detachment of cold iron during molding and may cause deformation of the casting, making the process difficult. This has a significant impact on the quality stability of the gearbox housing and increases the casting cost.

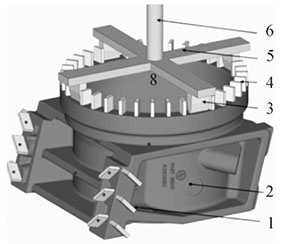

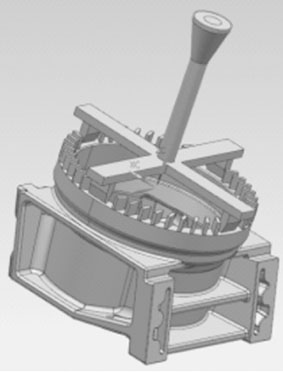

Two new lost foam casting processes have been developed to address the issue of hot spot shrinkage in ductile iron: heat dissipation process and flexible chill casting process. The core purpose of heat dissipation technology is to change the structure of the casting, reduce the modulus at the hot junction of the casting, and remove a large amount of heat with negative pressure gas during the solidification stage, which has a chilling effect. The specific method is to stick foam sheets at the hot spot of the casting, and then produce qualified castings through coating, drying, box molding, pouring and other processes. During the casting and solidification process of lost foam cast iron, negative pressure is continuously drawn, and during the operation of the negative pressure pump, cold air is cooled Gas enters the upper surface of the sand box and undergoes heat exchange with the casting and heat dissipation fins to remove heat. The heat dissipation fins have a larger specific surface area, reducing the local modulus of the casting. Cold air takes away a large amount of heat, and the local molding sand in contact with the casting and heat dissipation fins forms a microchannel flow heat exchange, forming a cooling zone with a large temperature difference. The heat dissipation fins act as cold iron, making the local solidification mode of the casting change to sequential solidification, eliminating shrinkage holes, porosity and defects in the casting The process of sinking and cooling fins also has advantages: simple and convenient operation; The casting process has little impact; Almost does not affect the production rate of the gearbox housing casting process; The post-processing of the gearbox housing is simple.

Conclusion

(1) Inclusion defects caused by insufficient cracking of pattern foam materials are inevitable in EPC. However, through the process method of adding allowance on the end face of the casting, the inclusions will be gathered inside the process allowance, and the process allowance will be removed to finally obtain qualified castings without inclusion defects.

(2) The shrinkage of ductile iron parts produced by lost foam casting due to hot spots is difficult to process using traditional riser and chill casting methods. Therefore, a new process method, namely the heat sink process, has been designed. Install a certain number of heat dissipation fins at the hot nodes of castings to enhance local heat dissipation speed and eliminate geometric hot nodes, thereby solving shrinkage defects in castings. The heat sink process has passed the verification of the gearbox housing casting, proving that this process meets the design requirements and can solve the shrinkage cavity defect of the casting. This is a new method of disappearing mold casting to solve shrinkage cavity.

(3) The flexible cold iron process solves the problems of deformation of cold iron model clusters in lost foam casting and can effectively eliminate shrinkage defects in castings.