Let’s examine some common casting defects in detail:

- Porosity:

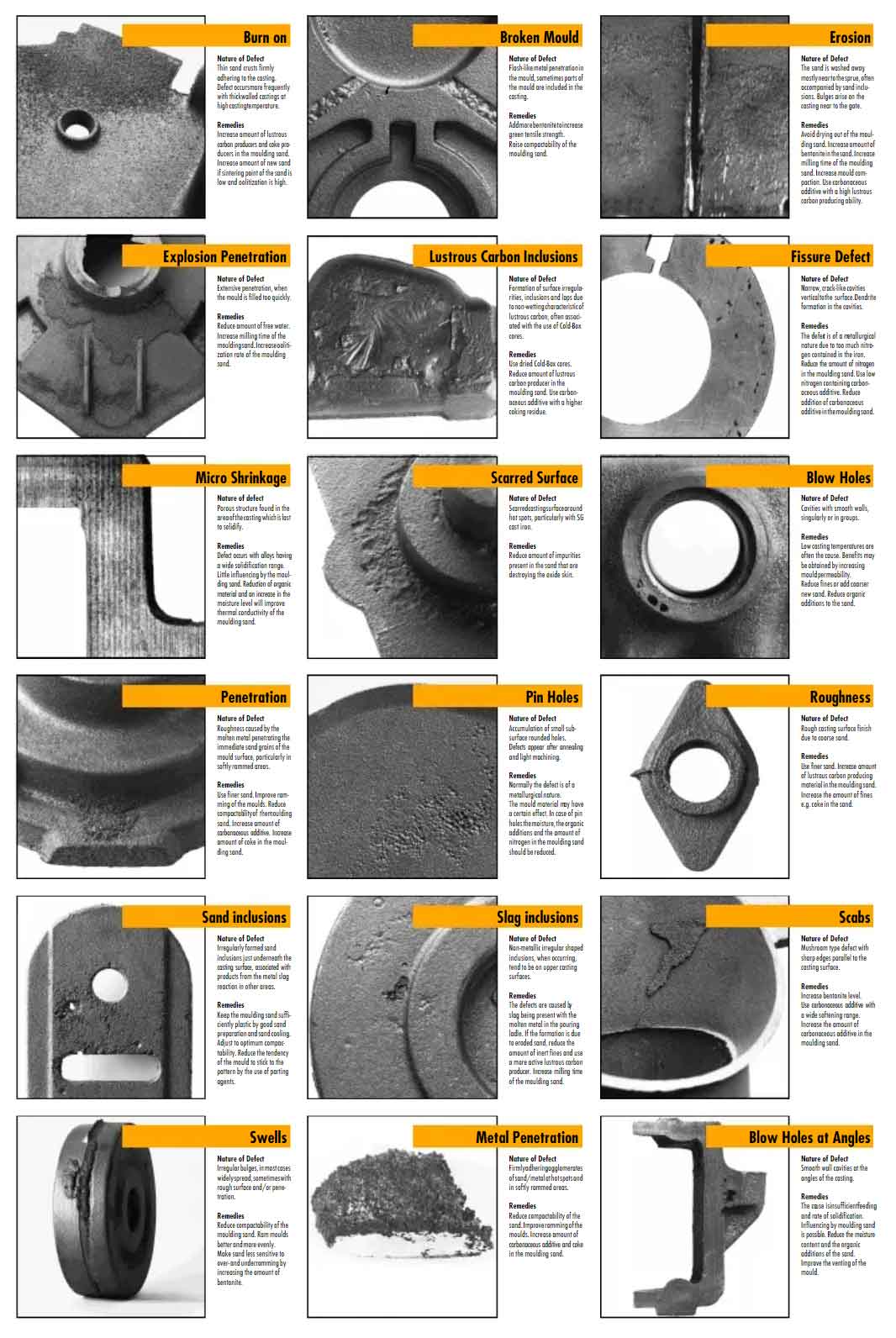

- Description: Porosity refers to the presence of voids or gas pockets within the cast metal. It can appear as small holes, cavities, or clusters of voids.

- Causes: Porosity can occur due to various reasons, including gas entrapment, inadequate degassing, moisture or volatile materials, improper mold venting, or high pouring temperatures.

- Impact: Porosity can weaken the castings, reduce their density, and compromise their structural integrity.

- Prevention and Remedies: Proper mold design, controlled pouring techniques, effective degassing, adequate venting, and appropriate material selection are some strategies to minimize porosity. Non-destructive testing methods like X-ray or ultrasound can help identify and address porosity issues.

- Shrinkage:

- Description: Shrinkage refers to the reduction in volume that occurs during solidification, resulting in voids or shrinkage cavities within the casting.

- Causes: Shrinkage defects occur due to the inadequate feeding of molten metal to compensate for solidification shrinkage, leading to insufficient material in certain areas.

- Impact: Shrinkage defects can compromise the structural integrity of the casting, resulting in localized weak spots and dimensional inaccuracies.

- Prevention and Remedies: Proper gating and risering design, use of chills or cooling devices, controlled cooling rates, and optimized pouring techniques can help minimize shrinkage defects. Simulation software can assist in identifying potential shrinkage-prone areas and optimizing the casting process parameters.

- Inclusions:

- Description: Inclusions are foreign materials or impurities present within the casting. They can be non-metallic, such as oxides, slag, or sand, or metallic in nature.

- Causes: Inclusions can occur due to contaminants in the melt, improper melting or metal treatment processes, inadequate mold preparation, or mold-metal reactions.

- Impact: Inclusions can weaken the casting, reduce its mechanical properties, and lead to premature failure.

- Prevention and Remedies: Proper metal melting and treatment, effective filtration methods, suitable mold coatings, and careful material selection can help minimize inclusion defects. Inspection techniques like visual examination and non-destructive testing aid in detecting and addressing inclusions.

- Cold Shut:

- Description: Cold shut refers to a casting defect where the metal flow does not fully fuse together during solidification, resulting in a visible line or seam in the casting.

- Causes: Cold shuts occur when two streams of metal do not merge properly due to insufficient fluidity, improper gating design, or inadequate mold filling.

- Impact: Cold shuts can weaken the casting along the seam, leading to potential leakage, reduced strength, and compromised surface finish.

- Prevention and Remedies: Proper gating and risering design, adequate metal fluidity, optimized pouring techniques, and controlled solidification rates can minimize the occurrence of cold shuts. Process monitoring and quality inspections help identify and rectify such defects.

- Misrun:

- Description: Misrun is a defect where the molten metal does not completely fill the mold cavity, resulting in an incomplete casting.

- Causes: Misruns can happen due to inadequate pouring temperature, poor mold filling, improper gating design, or blockage in the mold cavity.

- Impact: Misruns lead to incomplete or improperly shaped castings, rendering them unusable and requiring rework or scrap.

- Prevention and Remedies: Proper pouring techniques, optimized gating and risering design, suitable mold coatings, and adequate mold venting can minimize misruns. Process control, including monitoring of pouring temperature and mold filling, helps ensure complete mold cavity filling.

These are just a few examples of common casting defects. Other defects include surface irregularities (such as rough surfaces, cracks, or hot tearing), dimensional variations, and mold-related issues. Each defect has its specific causes and remedies, and a comprehensive defect analysis approach is essential for effective defect prevention and control.