In the production of large and medium-sized ductile iron castings, which are critical components in high-end equipment such as automotive, machinery, and infrastructure sectors, the prevention of shrinkage defects is paramount. Ductile iron casting exhibits a unique solidification behavior characterized by a mushy or paste-like mode, as opposed to the layer-by-layer solidification seen in steels. This mushy solidification results in narrow feeding channels, making effective riser systems essential to compensate for solidification shrinkage. Although the graphite expansion during solidification of ductile iron casting provides some self-feeding effect, it is often insufficient for larger sections, necessitating the use of risers with exothermic insulating covering agents to ensure sound castings. The performance of these covering agents directly impacts metal yield, energy consumption, and environmental footprint, driving ongoing innovation in this field.

Conventional exothermic insulating covering agents for ductile iron casting risers often rely on high contents of fluorides (e.g., cryolite, Na3AlF6) to catalyze aluminothermic reactions and act as fluxing agents, and carbonaceous materials (e.g., carbonized rice hull) to enhance exothermic and insulating properties. However, excessive fluoride can lead to graphite coarsening or degeneration at the riser-contact zone in ductile iron casting, compromising mechanical properties. Moreover, high carbon content in the covering agent can contaminate the remelted riser metal, affecting the chemical composition of subsequent ductile iron casting production. Therefore, there is a pressing need for low-fluoride, low-carbon, and cost-effective alternatives that balance exothermic performance, insulation, and environmental friendliness for ductile iron casting applications.

In this study, we developed a novel exothermic insulating covering agent specifically designed for large and medium-sized ductile iron casting risers. The formulation utilizes fly ash cenospheres (a waste by-product from thermal power plants) and natural perlite as primary insulating materials, aluminum powder and low-cost industrial iron oxide powder as main exothermic materials, nitrate-based mixtures as oxidizers, and strictly controlled amounts of fluoride salts (as catalysts and fluxing agents) and carbonized rice hull (as an exothermic and insulating aid). This approach aims to achieve an optimal balance of ignition temperature, ignition time, heat release rate, total heat output, and production cost, while minimizing environmental impact for ductile iron casting processes. The key performance targets for this new covering agent include moisture content ≤1.0%, fluoride content ≤1.0%, carbon content ≤5.5%, exothermic temperature range of 300–1,000°C, and total heat release ≥170 J/g.

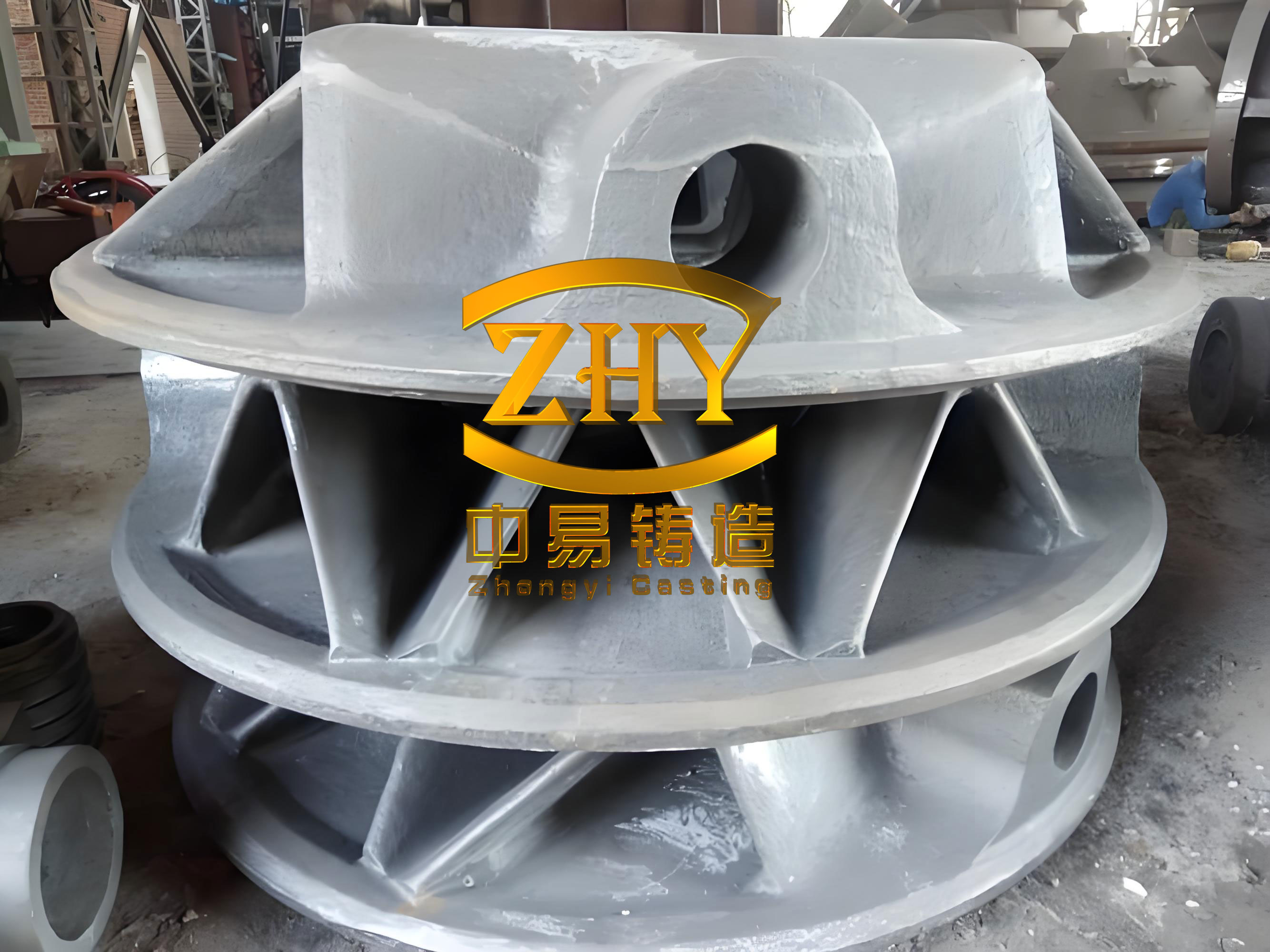

To comprehensively evaluate the feeding effectiveness of this novel covering agent for ductile iron casting, we conducted comparative field trials at multiple foundries in China, pitting it against similar products from two renowned companies—one domestic and one international. The trials focused on actual production of various ductile iron casting components, such as rail castings, pad iron castings, and pump cover castings. We employed a new metric, the “relative feeding efficiency of the riser,” to more accurately characterize riser performance in ductile iron casting, as traditional feeding efficiency metrics fail to account for the shape of the shrinkage cavity (i.e., riser safety height). This paper details our methodology, results, and analysis, emphasizing the advantages of the novel covering agent for ductile iron casting applications.

The feeding capability of a riser in ductile iron casting is traditionally quantified by the feeding efficiency, denoted as η, which represents the volume of liquid metal fed into the casting divided by the total volume of the riser. Mathematically, it is expressed as:

$$\eta = \frac{M_{\text{feed}}}{M_{\text{riser}}} \times 100\% = \frac{V_{\text{feed}}}{V_{\text{riser}}} \times 100\%$$

where \(M_{\text{feed}}\) and \(V_{\text{feed}}\) are the mass and volume of the fed liquid metal (i.e., the shrinkage cavity volume in the riser), and \(M_{\text{riser}}\) and \(V_{\text{riser}}\) are the total mass and geometric volume of the riser. However, this metric solely considers the total shrinkage volume and ignores the shape of the shrinkage cavity. In practice, an ideal riser for ductile iron casting should not only have a large shrinkage volume but also a flat-top shrinkage profile, indicating a high safety height (the distance from the top of the shrinkage cavity to the top of the riser). A high safety height allows for potential reduction in riser height and volume, thereby improving metal yield in ductile iron casting production.

To address this limitation, we propose a new metric termed the “relative feeding efficiency of the riser,” denoted as \(\eta_{\text{relative}}\). This metric considers both the shrinkage volume and the shape of the shrinkage cavity by relating the shrinkage volume to the geometric volume of the upper portion of the riser corresponding to the shrinkage depth. The formula is given by:

$$\eta_{\text{relative}} = \left( \frac{V_{\text{feed}}}{V_{\text{riser,upper}}} \right) \times 100\% = \left[ \frac{V_{\text{feed}}}{V_{\text{riser}} – V_{\text{riser,lower}}} \right] \times 100\%$$

where \(V_{\text{riser,upper}}\) is the geometric volume of the upper part of the riser above the safety height, \(V_{\text{riser,lower}}\) is the geometric volume of the lower part of the riser below the safety height (i.e., corresponding to the safety height \(H\)), and \(V_{\text{riser}}\) is the total geometric volume of the riser. This metric better reflects the actual feeding capacity and effectiveness of the riser in ductile iron casting, as it penalizes irregular shrinkage shapes that reduce safety height.

Our testing methodology for evaluating covering agents in ductile iron casting involved the following steps. First, we selected casting molds with multiple identical risers (e.g., two or more per mold) for the same ductile iron casting component. During pouring of the ductile iron melt, when the metal level reached approximately half the riser height, we applied equal masses of the covering agents (the novel agent and the comparative products) onto the riser tops, spreading them evenly to form uniform layers. After cooling to room temperature, the risers were severed from the ductile iron casting using oxy-acetylene torches. The shrinkage cavity volume \(V_{\text{feed}}\) was measured by filling it with fine quartz sand (100/200 mesh), weighing the sand, and converting to volume. Subsequently, each riser was sectioned longitudinally via wire cutting to expose the shrinkage profile. The shrinkage depth and safety height were measured, allowing calculation of \(V_{\text{riser,upper}}\) based on riser geometry. Finally, \(\eta_{\text{relative}}\) was computed using the above formula. Visual documentation of riser top surfaces and cross-sectional morphologies was also performed to qualitatively assess feeding performance in ductile iron casting.

The trials encompassed three distinct ductile iron casting types to ensure robustness. Below, we summarize the results for each ductile iron casting component, with data presented in tables to facilitate comparison.

For the rail casting, a component used in ship lock gates with a weight of about 980 kg and material QT400-15, each mold produced one ductile iron casting with two identical elliptical open risers (230 mm × 330 mm × 400 mm). The riser sides were insulated with cenosphere insulating sleeves, and the tops were treated with 1.0 kg each of the novel covering agent and a domestic知名 company’s product. The observed riser profiles and shrinkage morphologies are depicted in the figures, though not referenced numerically here. Key quantitative results are tabulated below:

| Covering Agent Type | Total Riser Height (mm) | Safety Height (mm) | Max. Shrinkage Depth (mm) | Shrinkage Cavity Volume (dm³) | Upper Riser Volume Corresponding to Shrinkage Depth (dm³) | Traditional Feeding Efficiency η (%) | Relative Feeding Efficiency \(\eta_{\text{relative}}\) (%) |

|---|---|---|---|---|---|---|---|

| Novel Covering Agent | 270 | 160 | 110 | 3.55 | 7.10 | 20.4 | 50.0 |

| Domestic Company’s Product | 270 | 175 | 95 | 2.96 | 6.13 | 17.0 | 48.3 |

From this table, it is evident that for the rail ductile iron casting, the novel covering agent achieved a higher traditional feeding efficiency (20.4% vs. 17.0%) and a slightly higher relative feeding efficiency (50.0% vs. 48.3%). The novel agent also exhibited faster ignition, better spreadability, and a more uniform insulating layer during combustion, which is beneficial for ductile iron casting given the lower pouring temperatures and rapid cooling of smaller risers typical in ductile iron casting production.

For the pad iron ductile iron casting, weighing 730 kg with material QT500-7, each mold contained three identical circular open risers (diameter 100 mm, height 325–355 mm). Riser sides used cenosphere sleeves, and tops were treated with equal amounts of the novel agent and an international renowned company’s product. The shrinkage morphologies showed that the novel agent produced a larger and flatter-bottomed shrinkage cavity with a depth of 55 mm, whereas the comparative product yielded a smaller, irregular-shaped cavity with a depth of 45 mm (excluding hidden shrinkage). Although hidden shrinkage precluded precise volume measurement for traditional efficiency calculation, the relative feeding efficiency was clearly superior for the novel agent due to its higher safety height and more favorable shrinkage shape in this ductile iron casting. Metallographic examination of the riser roots in the pad iron ductile iron casting revealed no graphite coarsening or spheroidization degradation for either agent, with both showing spheroidal and vermicular graphite, spheroidization grades of 80–90%, and graphite size ratings of 6, confirming the low fluoride content (≤1.0%) of the novel agent does not adversely affect graphite morphology in ductile iron casting.

For the pump cover ductile iron casting, weighing about 1 ton with material QT600-3, each mold featured multiple identical circular open risers (diameter 105 mm). Interestingly, riser sides were uninsulated in this trial, highlighting the topping coverage’s role. The tops were treated with the novel agent and the same international company’s product. Combustion observations indicated that the novel agent ignited earlier, peaked earlier, and completed exothermic reaction about 1 minute sooner than the comparative product, aligning with the needs of ductile iron casting where quick heat supplementation is crucial. The novel agent also formed a thicker, more insulating post-combustion layer, with only minor central red spots, whereas the comparative product’s layer was thinner with extensive red exposure, indicating poorer insulation. Shrinkage profiles showed that the novel agent produced a flat-bottomed shrinkage with a safety height of 82 mm, while the comparative product yielded an irregular shape with a safety height of only 58 mm. Again, hidden shrinkage prevented traditional efficiency computation, but the relative feeding efficiency was markedly higher for the novel agent in this ductile iron casting.

To delve deeper into the exothermic behavior, we performed differential scanning calorimetry (DSC) analysis on the novel covering agent and the domestic company’s product. The DSC curves, plotted as heat flow versus temperature, provide insights into the exothermic reaction kinetics. The novel agent’s DSC curve exhibited three distinct, well-separated exothermic peaks over a broad temperature range, whereas the domestic product’s curve showed less pronounced peaks concentrated in a narrower range corresponding to mid-to-late solidification stages. Quantitative DSC data for the novel covering agent are summarized below:

| Exothermic Stage | Temperature Range (°C) | Peak Heat Flow Rate (W/g) | Peak Temperature (°C) | Enthalpy Change (Heat Release) (J/g) |

|---|---|---|---|---|

| Initial Stage | 245–385 | 0.14 | 280 | 21.57 |

| Middle Stage | 385–545 | 0.13 | 475 | 25.77 |

| Final Stage | 545–1,100 | 0.11 | 690 | 122.72 |

| Total Enthalpy Change | 170.06 | |||

The total heat release of 170.06 J/g for the novel agent exceeds the target of ≥170 J/g and is higher than that of the domestic product (which showed lower cumulative heat flow in DSC). The three-stage exothermic profile ensures sustained heat supply throughout the solidification of ductile iron casting, particularly critical during early stages when riser cooling is rapid. The formulation strategy of combining aluminothermic reactions (via Al and Fe2O3) with slower oxidative reactions from carbonaceous materials (in controlled amounts) enables this tailored exothermic behavior for ductile iron casting applications.

The low fluoride content (≤1.0%) in the novel covering agent is instrumental in preserving graphite quality in ductile iron casting. Fluorides, while effective as catalysts and flux, can promote graphite degeneration at the riser-casting interface if excessive. Our metallurgical analysis across trials confirmed that the novel agent induced no graphite coarsening or spheroidization defects in ductile iron casting, with graphite spheres remaining fine and well-formed. This aligns with industry requirements for high-integrity ductile iron casting, especially in demanding applications.

Furthermore, the use of industrial by-products (fly ash cenospheres) and natural minerals (perlite) enhances the sustainability and cost-effectiveness of the novel covering agent for ductile iron casting. Cenospheres provide excellent insulation due to their hollow spherical structure, while perlite expands upon heating, improving coverage. The controlled addition of carbonized rice hull (≤5.5% carbon) offers supplemental exothermic and insulating benefits without risking carbon pickup in remelted riser metal for ductile iron casting, as the carbon content remains within tolerable limits for ductile iron chemistry control.

In comparing the novel agent with the international product, we note that the latter often relies on higher fluoride and carbon contents for performance, which can pose environmental and quality challenges for ductile iron casting. The novel agent’s faster ignition and thicker insulating layer contribute to its superior relative feeding efficiency, as evidenced in the pad iron and pump cover ductile iron casting trials. The relative feeding efficiency metric proves more discriminative than traditional efficiency, as it captures the combined effect of shrinkage volume and safety height—key for optimizing riser design in ductile iron casting.

To generalize, the performance of an exothermic insulating covering agent for ductile iron casting risers can be modeled based on heat transfer and solidification dynamics. The heat balance in the riser can be expressed as:

$$Q_{\text{exo}} + Q_{\text{ins}} = Q_{\text{loss}} + Q_{\text{feed}}$$

where \(Q_{\text{exo}}\) is the exothermic heat from the covering agent, \(Q_{\text{ins}}\) is the insulating effect reducing heat loss, \(Q_{\text{loss}}\) is the heat lost to the surroundings, and \(Q_{\text{feed}}\) is the heat required to feed the shrinkage in the ductile iron casting. For optimal performance in ductile iron casting, \(Q_{\text{exo}}\) should be sufficiently high and timely to offset \(Q_{\text{loss}}\), extending the riser’s liquid lifespan. The novel agent’s DSC profile indicates that \(Q_{\text{exo}}\) is distributed across a wide temperature range, matching the solidification curve of ductile iron casting, which typically has a long mushy zone.

The relative feeding efficiency \(\eta_{\text{relative}}\) can also be derived from geometric considerations. For a cylindrical riser of diameter \(D\) and total height \(H_{\text{total}}\), with a shrinkage cavity of depth \(h_{\text{shrink}}\) and safety height \(H_{\text{safe}}\), the volumes are:

$$V_{\text{feed}} = \frac{\pi D^2}{4} \cdot h_{\text{shrink}} \cdot f_{\text{shape}}$$

$$V_{\text{riser,upper}} = \frac{\pi D^2}{4} \cdot h_{\text{shrink}}$$

where \(f_{\text{shape}}\) is a shape factor (≤1) accounting for non-ideal shrinkage cavity geometry (e.g., conical, irregular). For a perfectly flat-bottomed shrinkage, \(f_{\text{shape}} \approx 1\). Thus, \(\eta_{\text{relative}} = f_{\text{shape}} \times 100\%\). In our trials, the novel agent achieved \(f_{\text{shape}}\) values closer to 1 (e.g., 0.50 for rail casting) compared to competitors, indicating superior shrinkage shape control in ductile iron casting.

Another aspect is the environmental impact. The novel agent’s low fluoride content reduces fluoride emissions during combustion, improving workplace safety and reducing pollution in ductile iron casting foundries. Additionally, the utilization of fly ash cenospheres, a waste material, supports circular economy principles in ductile iron casting production.

In conclusion, our comprehensive study demonstrates that the novel exothermic insulating covering agent developed for large and medium-sized ductile iron casting risers offers significant advantages. It achieves a balanced exothermic profile with low fluoride and carbon contents, ensuring high feeding efficiency without compromising graphite quality in ductile iron casting. The proposed relative feeding efficiency metric, \(\eta_{\text{relative}}\), provides a more accurate assessment of riser performance in ductile iron casting by incorporating both shrinkage volume and safety height. Field trials on various ductile iron casting components show that the novel agent outperforms competing products from renowned companies, with relative feeding efficiencies up to 50%, faster ignition, better insulation, and environmental benefits. This innovation holds promise for enhancing the quality and sustainability of ductile iron casting production in high-end equipment manufacturing.

Future work could focus on optimizing the covering agent’s composition for specific ductile iron casting grades or automating its application in foundries. Further studies might explore the thermal conductivity and emissivity properties of the insulating layer to refine heat transfer models for ductile iron casting risers. Nonetheless, the current results validate the effectiveness of this novel covering agent for advancing ductile iron casting technology.