High-performance steel casting has emerged as a critical component in modern construction and infrastructure projects. The unique properties of high-performance steel, such as enhanced strength, durability, and resistance to environmental factors, make it an ideal material for a wide range of applications. This article explores the use of high-performance steel casting in construction and infrastructure, highlighting its benefits, current trends, and future prospects, supported by detailed tables and lists for better understanding.

Introduction

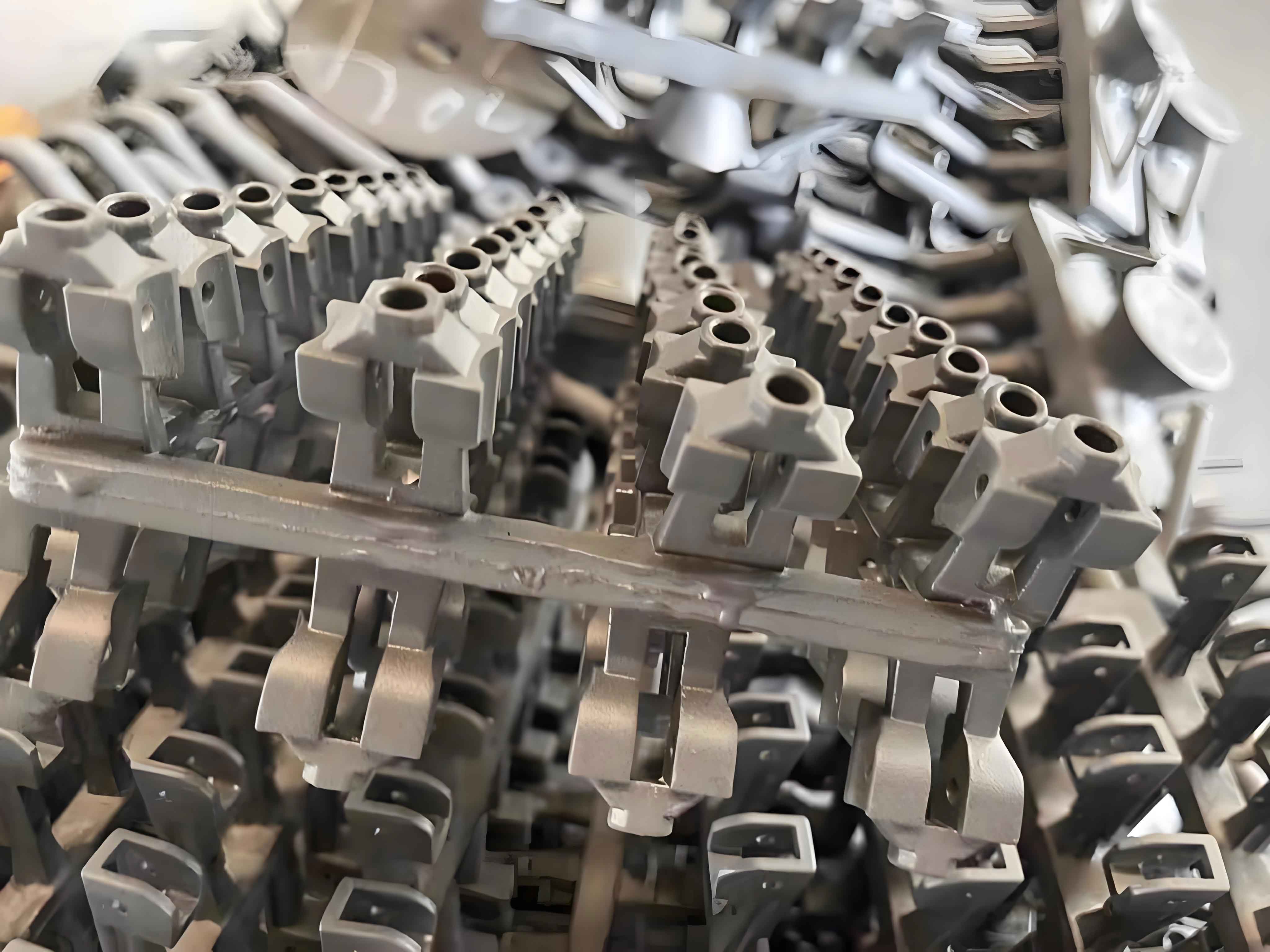

High-performance steel casting involves the use of advanced steel alloys and precise casting techniques to produce components with superior mechanical properties. These components are essential in construction and infrastructure projects where reliability, longevity, and safety are paramount. From bridges and buildings to transportation systems and utilities, high-performance steel casting provide the foundation for robust and resilient structures.

Benefits of High-Performance Steel Casting in Construction and Infrastructure

- Enhanced Strength and Durability:

- High-performance steel casting offer exceptional tensile strength and resistance to wear and tear, ensuring the longevity of structures.

- Corrosion Resistance:

- Advanced alloy compositions provide superior resistance to corrosion, extending the lifespan of components exposed to harsh environmental conditions.

- Design Flexibility:

- The steel casting process allows for the creation of complex shapes and geometries, enabling innovative architectural and engineering designs.

- Cost-Effectiveness:

- Despite the initial cost, the long-term benefits of reduced maintenance and replacement costs make high-performance steel casting cost-effective choice.

Table: Benefits of High-Performance Steel Casting

| Benefit | Description | Impact on Construction and Infrastructure |

|---|---|---|

| Enhanced Strength | Exceptional tensile strength and wear resistance | Increased structural integrity and lifespan |

| Durability | Long-lasting performance under various conditions | Reduced maintenance and replacement costs |

| Corrosion Resistance | Superior resistance to environmental factors | Extended lifespan of exposed components |

| Design Flexibility | Ability to create complex shapes and innovative designs | Greater architectural and engineering possibilities |

| Cost-Effectiveness | Long-term savings through reduced maintenance and replacement | Lower overall lifecycle costs |

Applications of High-Performance Steel Casting in Construction and Infrastructure

- Bridges:

- Steel casting is used in critical bridge components such as supports, beams, and joints, providing strength and durability to withstand heavy loads and environmental stresses.

- Buildings:

- High-performance steel casting is employed in structural frameworks, reinforcing bars, and load-bearing elements, ensuring the safety and stability of high-rise buildings.

- Transportation Systems:

- Components for railways, highways, and airports benefit from the enhanced mechanical properties of steel casting, contributing to the reliability and safety of transportation infrastructure.

- Utilities and Public Works:

- Steel casting is used in water and sewage systems, power generation facilities, and other public utilities, providing durable and corrosion-resistant solutions.

List: Key Applications of High-Performance Steel Casting

- Bridges: Supports, beams, joints

- Buildings: Structural frameworks, reinforcing bars, load-bearing elements

- Transportation Systems: Railway components, highway structures, airport facilities

- Utilities and Public Works: Water and sewage systems, power generation facilities

Current Trends in High-Performance Steel Casting

- Sustainable Construction Practices:

- The use of high-performance steel casting aligns with sustainable construction practices, focusing on durability and resource efficiency.

- Innovative Casting Techniques:

- Advanced casting techniques such as precision casting, vacuum casting, and 3D printing are being adopted to enhance the quality and performance of steel casting.

- Integration of Smart Technologies:

- Incorporating sensors and IoT devices in steel cast components for real-time monitoring and maintenance, improving the overall lifecycle management of infrastructure.

- Development of New Alloys:

- Continuous research and development of new steel alloys with enhanced properties tailored to specific construction and infrastructure needs.

Table: Current Trends in High-Performance Steel Casting

| Trend | Description | Expected Benefits |

|---|---|---|

| Sustainable Construction | Focus on durability and resource efficiency | Reduced environmental impact, cost savings |

| Innovative Casting Techniques | Use of precision casting, vacuum casting, and 3D printing | Enhanced quality and performance |

| Smart Technologies Integration | Incorporation of sensors and IoT devices for real-time monitoring | Improved lifecycle management |

| New Alloy Development | R&D of new steel alloys with tailored properties | Optimized performance for specific applications |

Future Prospects for High-Performance Steel Casting

- Advanced Material Research:

- Ongoing research into new materials and alloys to further enhance the mechanical properties of steel casting, making them even more resilient and versatile.

- Automated and Digitalized Casting Processes:

- The adoption of automation and digitalization in casting processes to increase precision, reduce waste, and improve efficiency.

- Integration with Renewable Energy Projects:

- High-performance steel casting will play a crucial role in the construction of renewable energy infrastructure, such as wind turbines and solar farms.

- Global Infrastructure Development:

- With increasing investments in infrastructure worldwide, the demand for high-performance steel casting is expected to grow, driving innovation and development in the field.

List: Future Prospects for High-Performance Steel Casting

- Advanced Material Research: Development of new resilient and versatile alloys

- Automated and Digitalized Casting Processes: Increased precision, reduced waste, improved efficiency

- Integration with Renewable Energy Projects: Construction of wind turbines, solar farms

- Global Infrastructure Development: Growing demand driving innovation and development

Conclusion

The use of high-performance steel casting in construction and infrastructure is a testament to the material’s unmatched strength, durability, and versatility. As the industry continues to evolve, current trends such as sustainable practices, innovative casting techniques, and the integration of smart technologies are shaping the future of steel casting. The continued research and development of new alloys, coupled with automated and digitalized casting processes, will further enhance the role of high-performance steel in global infrastructure projects. By embracing these advancements, the construction and infrastructure sectors can achieve greater efficiency, reliability, and sustainability, ensuring a robust foundation for future development.