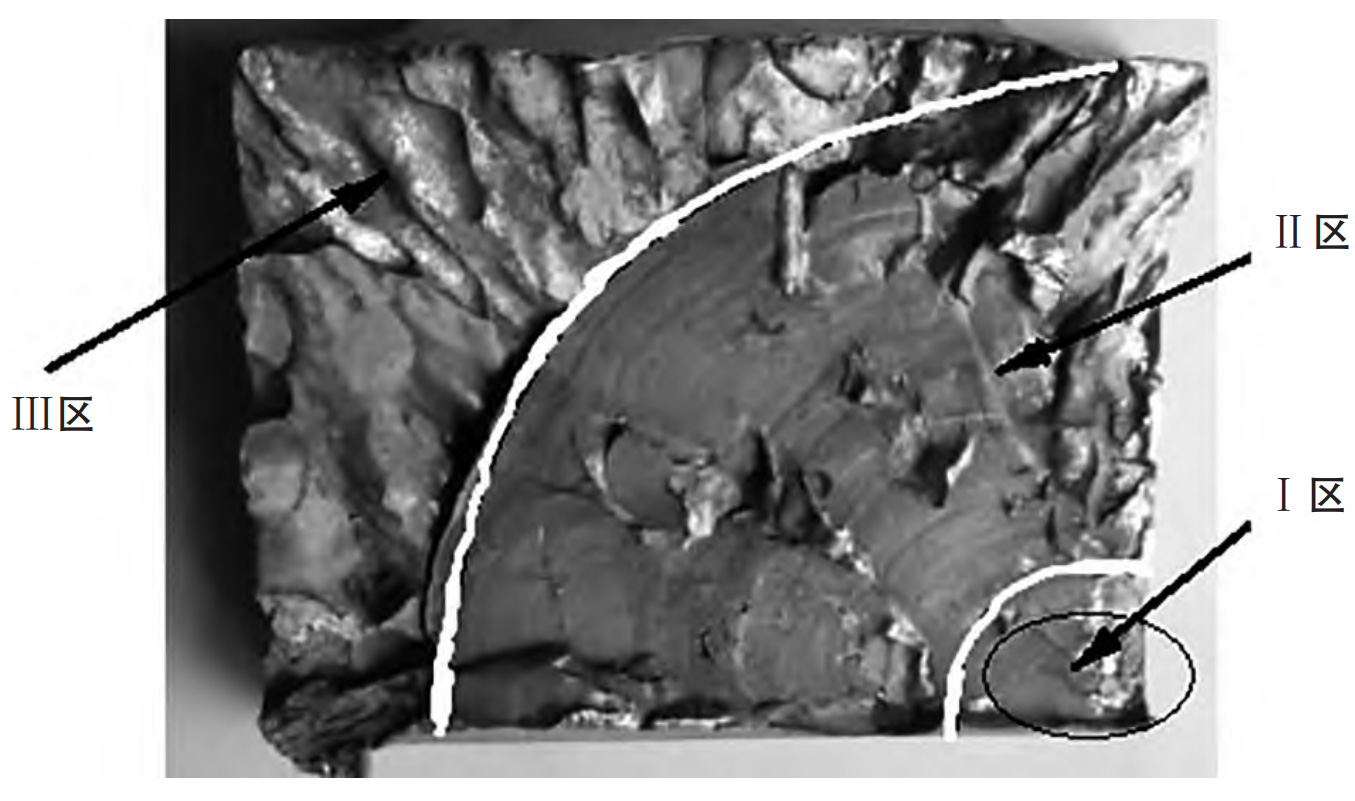

Analysis suggests that casting defects such as shrinkage porosity and cracks occur during the casting of the front support of steel castings, where shrinkage porosity and cracks are located right next to the shaft hole, forming stress concentration and becoming weak points. This part is a crucial load-bearing part of the boom, which will bear a large alternating load. Under the action of alternating load, it forms a fracture source and is the main cause of fracture.

Due to the high heating temperature, insufficient insulation time, and fast cooling rate of the normalizing heat treatment of steel castings, the Widmanstatten structure cannot be effectively eliminated, resulting in coarse grains, significantly reducing plasticity and impact toughness, and ultimately leading to fracture.