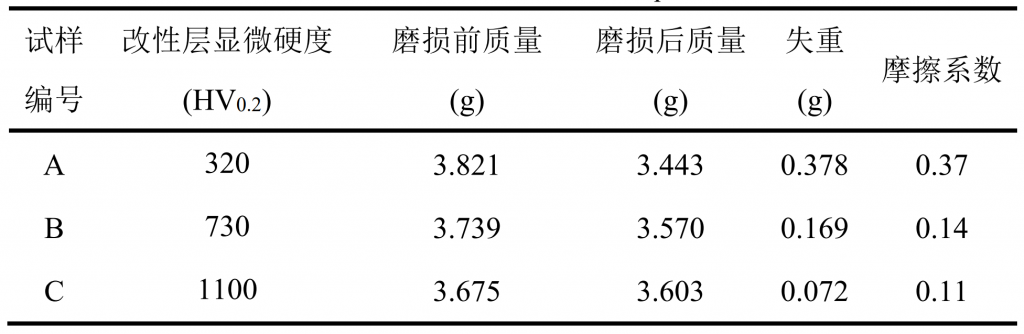

Friction coefficient and wear amount are important parameters to characterize the wear resistance of materials. The higher the surface hardness of materials, the lower the friction coefficient, and the smaller the wear amount, the better the wear resistance of corresponding materials. Select untreated grey cast iron sample a, fused grey cast iron sample B and laser fused impact grey cast iron sample C for friction and wear test. The wear loss of three kinds of grey cast iron samples after wear test under 20 N load is shown in the table. Compared with the original sample, The wear properties of gray cast iron samples after laser melting and laser melting impact have been greatly improved.

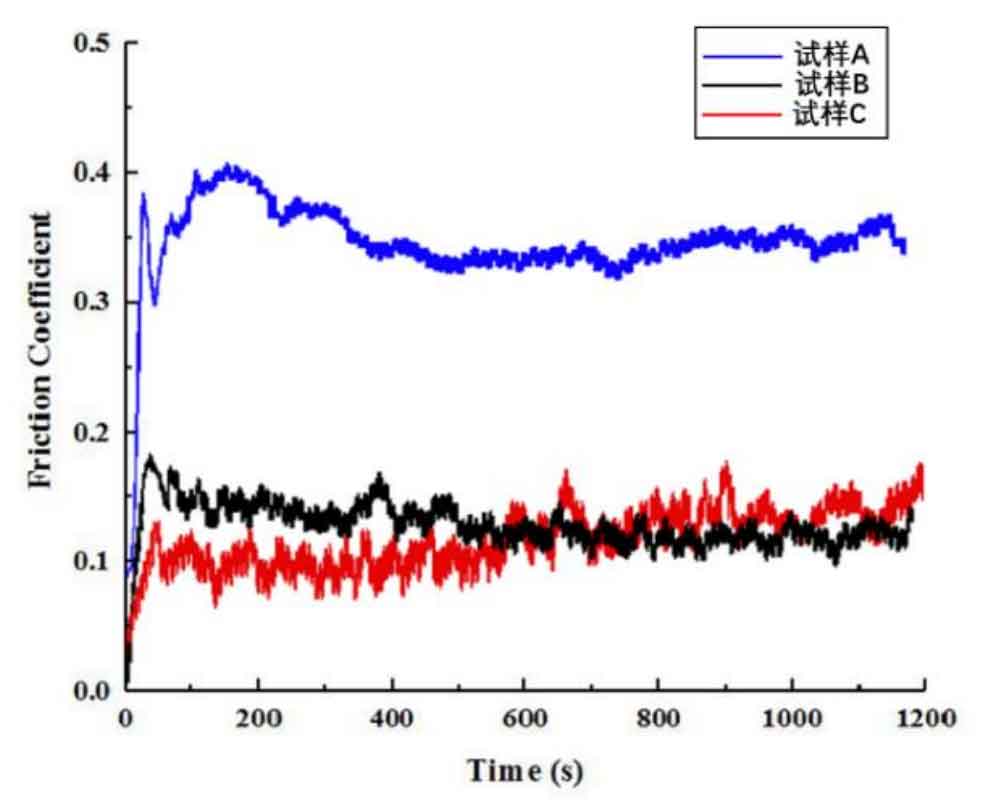

As shown in Figure 1, the dynamic friction coefficient versus time curves of three different gray cast iron sample surfaces under 20 N load are shown. Among them, the maximum friction coefficient of the original gray cast iron sample a is 0.37, and the maximum wear amount is 0.378 g. the amplitude of the friction coefficient curve fluctuates greatly, because the microhardness of the original gray cast iron sample surface is relatively low, The flake graphite in the matrix does serious harm to the wear surface strength, intensifies the surface damage in the wear process and increases the friction coefficient.

The friction coefficient of gray cast iron sample B after laser melting is 0.14. Compared with the untreated gray cast iron sample, the friction coefficient is greatly reduced and the wear amount is greatly reduced. Due to the high hardness of eutectic cementite produced by laser melting of gray cast iron, the dendritic long cementite structure plays a good supporting role in the process of friction and wear, so that the modified layer matrix is not easy to be peeled off and removed in the process of friction and wear. The average friction coefficient of gray cast iron sample C after laser impact is about 0.1, the minimum wear is 0.072 g, and the fluctuation range of friction coefficient is relatively small. Because the size of cementite is reduced and austenite grain is refined after laser shock, the hardness of the modified layer is further improved, so the wear resistance is the best. In the early stage of wear, the C curve of gray cast iron sample fluctuates less, and in the later stage of wear, the curve fluctuates greatly. It may be due to the formation of large wear debris particles after the peeling of hard and brittle carbides on the surface, which plays an abrasive effect, so as to increase the friction coefficient.

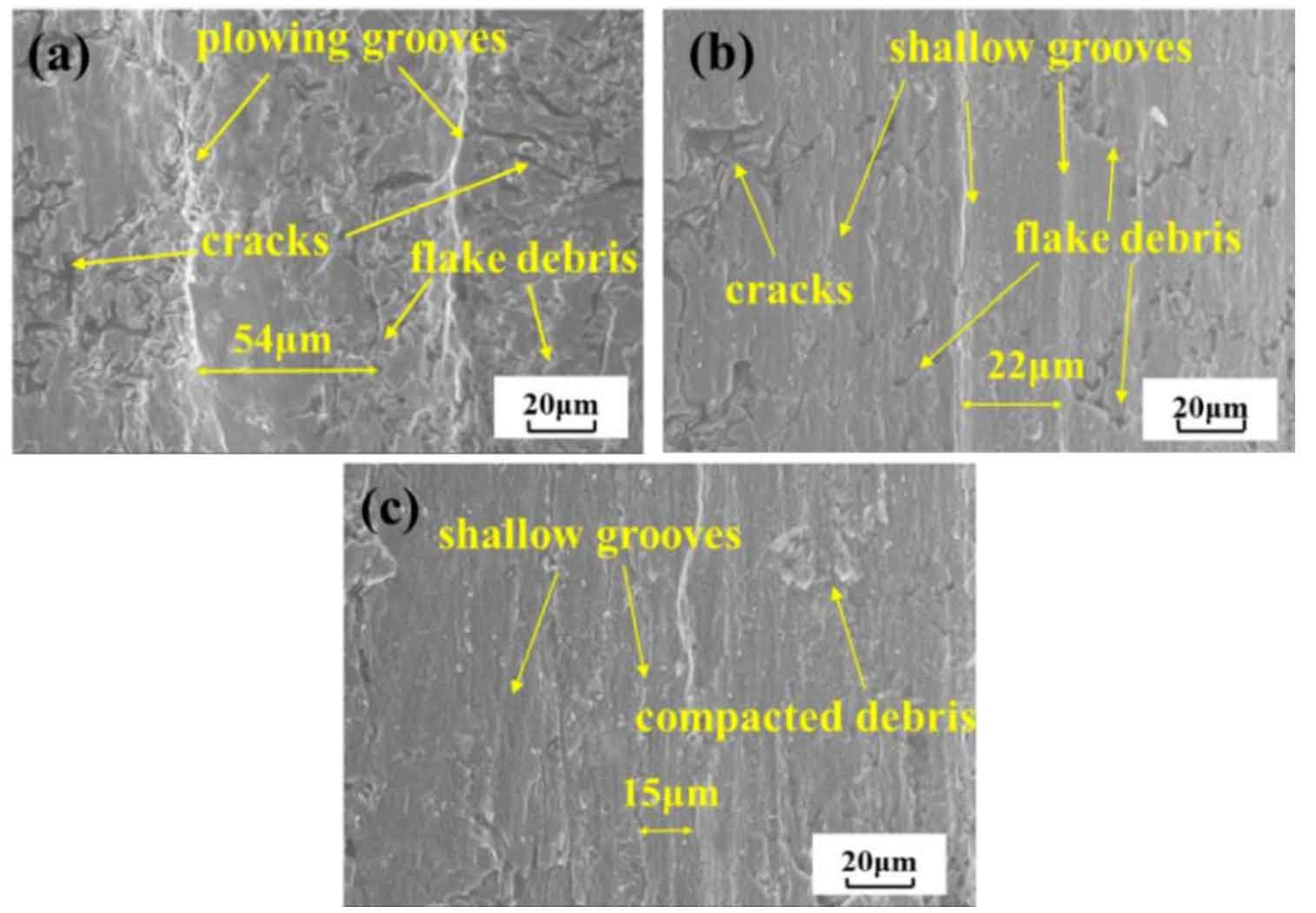

In order to study the wear mechanism under dry sliding wear, the surface morphology of gray cast iron samples after wear is studied, as shown in Figure 2. Figure 2 (a) shows the wear morphology of the surface of untreated gray cast iron sample. The surface hardness of untreated gray cast iron sample is low. Under the action of 20 N load, a large number of obvious furrows can be observed, and the furrows are deep, and the width of wear marks is about 54 μ m. The wear is serious. A large number of cracks and spalling can be observed on the worn surface. Due to the existence of a large amount of flake graphite on the surface of untreated gray cast iron sample a, the matrix near the graphite is damaged first under large load, and there will be small cracks at the tip of the graphite. The cracks expand along the groove and under the action of repeated stress, It will produce fatigue spalling and aggravate the wear of the surface of the original gray cast iron sample.

Figure 2 (b) shows the surface morphology of the gray cast iron sample after friction. The depth of the wear mark on the surface of the gray cast iron sample is shallow and the width of the wear mark is small, about 22 μ m. The hard cementite formed by laser melting of gray cast iron has very high hardness, which can effectively support the extrusion and chiseling of abrasive and has good wear resistance. However, after long-time friction under the cyclic force of high stress, many small cracks appear on the surface of gray cast iron melting layer, resulting in strip and thin-layer spalling. Due to the poor toughness of columnar cementite of gray cast iron melting layer, it is easy to break and crack in the wear process, which aggravates the wear.

Figure 2 (c) shows the wear morphology of the surface of gray cast iron sample after laser melting and impact. The wear mark on the surface of gray cast iron sample is the shallowest, and the wear mark width is significantly reduced to 15 μ m. The hardness of gray cast iron sample after laser impact is the highest, so there is almost no furrow on the worn surface, and there are few cracks on the worn surface. Because the melting layer produces plastic deformation after laser impact, and the direction of cementite in the deformation layer is parallel to the friction surface, the abrasive directly acts on the cementite surface with high hardness in the friction process, so the wear mark is shallow. The refinement of austenite grain after laser shock also effectively hinders the generation of wear surface cracks. Therefore, the surface of fused layer after laser shock has excellent wear resistance.