Sand casting is a versatile and ancient metal casting process that involves creating solid metal objects by pouring molten metal into a sand mold. The process is called sand casting because sand is the primary molding material used to create the mold cavity. Unraveling the intricacies of sand casting reveals a step-by-step process that combines craftsmanship, precision, and technology. Here’s a detailed overview of how sand casting works:

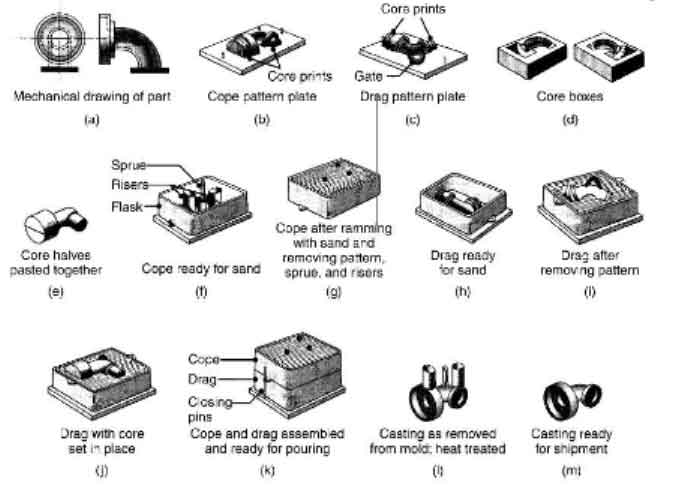

- Pattern Making: The first step in sand casting is creating a pattern, which is a replica of the final product in the desired shape and size. Patterns can be made from various materials, including wood, metal, or plastic. The pattern represents the negative space of the object to be cast, and its design must consider factors like shrinkage and draft angles.

- Mold Preparation: A mold consists of two halves – the cope and the drag. To prepare the mold, the pattern is placed in a box called a flask. The flask contains a molding material, typically a mixture of sand and a binder. The pattern is pressed into the sand, creating an impression. After removing the pattern, the flask is separated into cope and drag, and the two halves are put back together, leaving a cavity.

- Core Formation (Optional): In some cases, sand cores are used to create internal cavities or passages in the final casting. Cores are made from a similar sand mixture and are placed inside the mold before the mold halves are assembled.

- Pouring: Molten metal is prepared in a furnace and poured into the mold through a gate system. The gate allows the molten metal to flow into the mold and helps prevent defects during the solidification process.

- Solidification: Once the molten metal is poured into the mold, it starts to solidify and take the shape of the cavity created by the pattern. The solidification time depends on the metal type, size of the casting, and other factors.

- Cooling and Shakeout: After solidification is complete, the casting is left to cool and solidify further. Once cooled, the sand mold is broken apart, and the casting is removed. This process is known as shakeout.

- Finishing: The casting may undergo further processing, such as removing excess material (like runners and risers), cleaning, shot blasting, grinding, or machining to achieve the desired surface finish and dimensions.

- Inspection and Quality Control: The final castings are inspected to ensure they meet the required quality standards and specifications. Defective castings may be repaired or discarded.

- Reclaiming and Reusing Sand: The sand used in sand casting can be reclaimed and reused in subsequent molds, making sand casting a sustainable and cost-effective process.

Sand casting’s versatility, ability to produce complex shapes, and cost-effectiveness make it a popular choice in various industries, including automotive, aerospace, construction, art, and more. While traditional craftsmanship is still vital in pattern-making and mold preparation, modern technologies, such as computer-aided design (CAD) and simulation software, have optimized the process, ensuring higher accuracy and efficiency in modern sand casting practices.