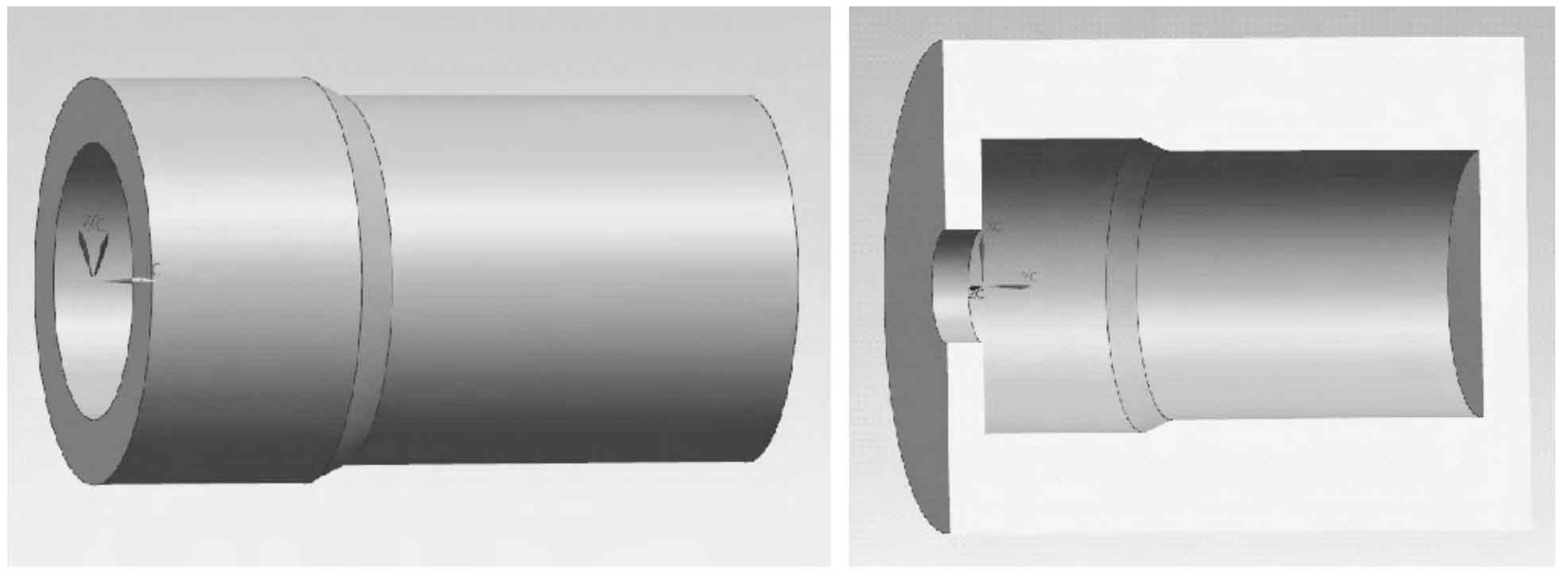

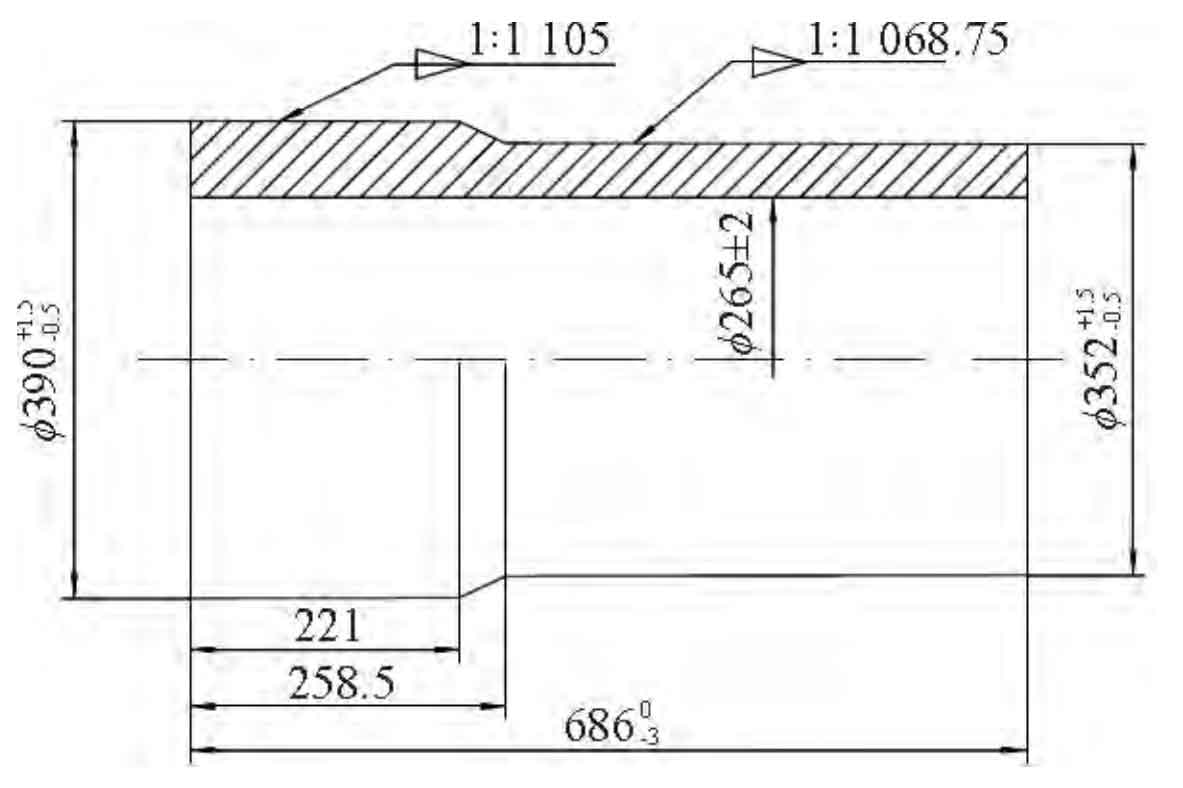

Man28-33d wet cylinder liner is selected as the research object. The blank length of cylinder liner is 686mm and the diameter of inner hole is φ 265mm, the diameter of the outer circle is φ 352~390mm。 Figure 1 shows the blank drawing of cylinder liner centrifugal casting drawn by CAXA software. The wall thickness ratio of mold to casting is about 2.0. The minimum wall thickness of mold is 50mm and the maximum is 149mm. Use UG software to draw the three-dimensional model of casting and mold, as shown in Figure 2. Import the three-dimensional model into ProCAST software, and select the finite element method to divide the two-dimensional and three-dimensional mesh of the casting and mold. The mesh size is 10mm, with a total of about 1.28 million meshes.

The cylinder liner is made of high molybdenum cast iron, and its composition is shown in table. The material composition is imported into ProCAST material database, and its thermophysical parameters are calculated. The solidus temperature of the alloy is 1057 ℃, and the liquidus temperature is 1277 ℃.

| C | Cr | Cu | Mn | Mo | Ni | P | S | Si | Fe |

| 2.75 | 0.42 | 0.36 | 0.75 | 0.74 | 0.43 | 0.27 | 0.055 | 1.8 | allowance |

The casting material is H13 steel, the preheating temperature is 200 ℃, the pouring temperature is 1430 ℃, the pouring time is 90s, the rotating speed is 700R / min, the heat transfer coefficient is 1000W / (M2 · K), and the boundary condition is set as free sliding boundary condition.