Abstract

The development process of high strength ductile iron casting QT700-2 eccentric body. Utilizing a combination of layered casting, cold iron application, and heat preservation riser technology, we achieved balanced solidification, eliminating shrinkage and porosity defects in the casting. During the melting process, we employed alloying, used a low-rare-earth spheroidizing agent, and implemented multiple inoculations to refine the graphite grains and stabilize the pearlite content. The resulting cast eccentric body met the customer’s requirements.

1. Introduction

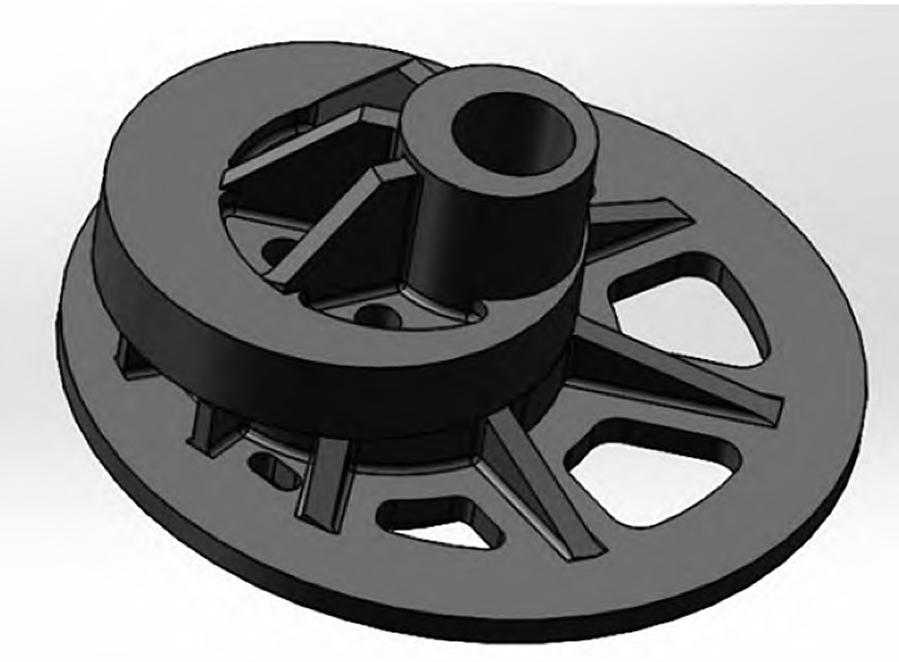

The eccentric body is a large-scale ductile iron casting in the press transmission system, converting the circumferential motion of the main gear into linear motion of the slider. It is characterized by stringent technical requirements: high dimensional accuracy (CT10) to ensure balance during operation, high strength and wear resistance with a surface hardness of over HB220 on the eccentric section, and a dense and uniform internal structure free from defects like shrinkage porosity, sand inclusion, slag inclusion, and cracks.

Given its complex structure, varying wall thickness (ranging from 50mm to a maximum of 320mm), and a mass of approximately 6000kg, the eccentric body poses significant challenges during casting. This paper presents the research and development process of as-cast QT700-2 eccentric body castings, emphasizing the casting process design, production control points, and production verification.

2. Casting Process Design

2.1 Gating System Design

The gating system is crucial for effective slag blocking and promoting feeding, minimizing the risk of shrinkage porosity. Considering the structural characteristics of the eccentric body casting, a layered gating system was adopted. The lower gating system was arranged on the bottom large disc, and the upper gating system was placed at the eccentric section, both using a closed design to ensure that the runner remained full during pouring, allowing slag to float to the top. The inner gates were dispersed across various parts of the casting to ensure a uniform temperature field, avoiding localized overheating.

Table 1. Design Parameters of the Gating System

| Gating System Type | Location | Design Feature |

|---|---|---|

| Layered Gating | Bottom | Closed Design |

| Layered Gating | Eccentric | Closed Design |

2.2 Riser Design

Although the eccentric body’s overall modulus exceeds 2.5cm, allowing for a no-riser process, strict requirements apply to the molten iron and pouring temperature. However, due to the poor process stability of the no-riser casting, heat preservation risers with a diameter of ø200mm were placed at the eccentric part and the top of the casting. These risers were primarily used for liquid feeding of the eccentric body, while the secondary shrinkage of the casting was compensated by the volume expansion caused by the precipitation of graphite spheres during solidification.

Table 2. Design Parameters of Heat Preservation Risers

| Riser Diameter | Location | Purpose |

|---|---|---|

| ø200mm | Eccentric | Liquid feeding and shrinkage control |

| ø200mm | Top | Liquid feeding and shrinkage control |

2.3 Cold Iron Design

To address the issues of graphite floating or crushed graphite defects in thick sections due to prolonged solidification, external cold iron was used to accelerate the cooling rate of these areas. The optimal thickness of the cold iron, which was 70mm (one-third of the casting wall thickness), was determined to avoid chill and fusion issues.

Table 3. Cold Iron Design Parameters

| Cold Iron Thickness | Location | Purpose |

|---|---|---|

| 70mm | Eccentric | Accelerate cooling rate |

3. Production Control Points

3.1 Chemical Composition Selection

Table 4. Chemical Composition of the As-cast Eccentric Body

| Element | Range | Function |

|---|---|---|

| C | 3.6%~3.7% | Increase graphite sphere count, reduce porosity |

| Si | 2.2%~2.4% | Increase fluidity, reduce porosity |

| Mn | 0.4%~0.6% | Stabilize and refine pearlite, eliminate ferrite |

| P | ≤0.06% | Avoid phosphorus eutectic, maintain mechanical properties |

| S | ≤0.02% | Avoid graphite spheroidization inhibition |

| Mg | 0.04%~0.06% | Spheroidizing agent residue control |

| Re | 0.02%~0.04% | Spheroidizing agent residue control |

| Cu | 0.7%~0.9% | Promote pearlite formation, increase strength |

| Cr | 0.1%~0.15% | Increase pearlite volume fraction, increase strength |

| Sn | 0.04%~0.05% | Eliminate ferrite, obtain pearlitic structure |

3.2 Alloying Element Addition

- Cu: Enhances pearlite formation, improving the uniformity of the casting’s structure and properties. The Cu content was controlled between 0.7% and 0.9%.

- Cr: Increases the volume fraction and promotes the granular shape of pearlite, enhancing strength. The Cr content was set at 0.1% to 0.15%.

- Sn: Increases the pearlite volume fraction and refines it. The Sn content was maintained between 0.04% and 0.05%.

3.3 Spheroidizing Treatment

Due to the long solidification time of thick-section ductile iron castings, defects such as spheroidization decline and abnormal graphite shapes may occur. Therefore, a light rare-earth spheroidizing agent was chosen. The spheroidizing agent was roasted before use, tamped down, and covered with silicon-barium-calcium inoculant. About 3kg of spheroidizing agent was added when one-third of the molten iron was poured into the ladle. The spheroidizing agent addition rate was 1.4% to 1.6%.

3.4 Inoculation Treatment

Given the long pouring and solidification times and slow cooling rate of the eccentric body, intensive inoculation was necessary. Two inoculations were employed: the first using a 50% silicon iron and 50% silicon-barium-calcium inoculant mixture, and the second, an in-stream inoculation with silicon-manganese-zirconium instant inoculant at a rate of 0.1%. The in-stream inoculation was applied uniformly and slowly over most of the pouring time.

3.5 Pouring Process

High-temperature and fast pouring were adopted. Although high-temperature pouring tends to increase the tendency of porosity, it reduces slag inclusion defects. The pouring temperature for the eccentric body was 1360°C to 1390°C, with no interruption during pouring. After pouring, two additional iron supplements were made.

4. Production Verification

The QT700-2 eccentric body castings produced using the aforementioned process had a pearlite content exceeding 85%. The mechanical properties of the attached test coupons are presented in Table 5. The microstructure of the eccentric section of the casting showed round and uniformly distributed graphite spheres, a dense matrix without inclusions, and a surface hardness exceeding HB220 in the thick eccentric part, meeting the customer’s requirements.

Table 5. Mechanical Properties of QT700-2 Test Coupons

| Batch | Ultimate Tensile Strength (MPa) | Elongation (%) |

|---|---|---|

| 1# | 716 | 3.0 |

| 2# | 729 | 3.5 |

| 3# | 735 | 3.5 |

| 4# | 710 | 3.5 |

| 5# | 725 | 3.0 |

5. Conclusion

(1) Heat preservation risers were used for liquid feeding of thick castings, ensuring process stability.

(2) Thick-section ductile iron castings are prone to casting defects such as spheroidization decay, inoculation decay, abnormal graphite, and graphite floating due to their long pouring and solidification times as well as slow cooling rates. Therefore, it is necessary to select pure furnace charge, control the carbon equivalent between 4.4% and 4.7%, add appropriate amounts of Cu, Cr, and Sn, use low-rare-earth spheroidizing agents, adopt a combination of pre-furnace inoculation and in-stream inoculation [4], and apply cold iron to accelerate the cooling rate of the thick sections of the eccentric body. These measures can eliminate fragmented graphite, refine graphite grains, stabilize the pearlite content, and produce eccentric bodies that meet customer requirements.