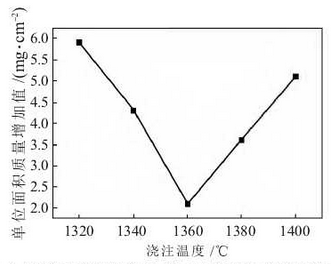

Figure 1 is a plot of the mass gain per unit area of a high temperature alloy sample prepared at different pouring temperatures.It can be seen from the diagram that with the pouring temperature increasing from 1320 (?) to 1400 (?) C, the unit area mass increment of the new superalloy sample for automotive supercharger turbine decreases first and then increases, and the high temperature oxidation resistance increases first and then decreases.This is because the smaller the mass increase per unit area, the better the high temperature oxidation resistance of the sample.When the pouring temperature is 1320 C, the initial mass of the sample is 21.352 g, the mass per unit area is 606.8 mg/cm2 and the mass per unit area is 5.9 mg/cm2. At this time, the mass per unit area increases the most and the oxidation resistance at high temperature is the worst.

The increase in mass per unit area of the sample decreases with increasing pouring temperature.When the pouring temperature rises to 1360 C, the mass increase per unit area of the sample reaches the minimum value of 2.1 mg/cm22, which is 64.4% lower than that at 1320 C. At this time, the high temperature oxidation resistance is the best.However, the higher the pouring temperature is, the better the pouring temperature is. When the pouring temperature is further increased to 1380 ~C and 1400 ~C, the unit area mass of the sample increases to 3.6 mg/cm2 and 5.1 mg/cm2, which is higher than that prepared at 1360 ~C. The high temperature oxidation resistance of the sample decreases.

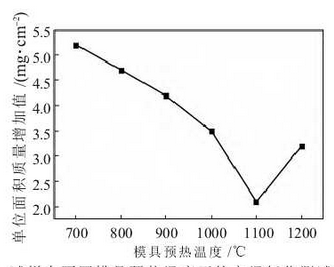

Figure 2 is a plot of the unit area mass gain of a high temperature alloy sample prepared at different die preheating temperatures.It can be seen from the diagram that as the preheating temperature of the die rises from 700 to 1200, the unit area mass increase of the superalloy sample decreases first and then increases, and the high temperature oxidation resistance increases first and then decreases.When the preheating temperature of the die is 700 C, the unit area mass increment of the sample is 5.2mg/cm2, at which time the unit area mass increment is the largest and the high temperature oxidation resistance is the worst.As the preheating temperature of the die increases gradually, the increase in mass per unit area of the sample decreases.

When the preheating temperature of the die rises to 1100 C, the mass increment per unit area of the sample reaches the minimum value of 2.1mg/cm2, which is 59.6% lower than that when the die is preheated at 700 C. At this time, the high temperature oxidation resistance is the best.However, the higher the preheating temperature of the die is not the better. When the preheating temperature of the die is further increased to 1200 C, the unit area mass of the sample increases by 3.2mg/cm2, which is higher than that of the preheating temperature of the die at 1100 C. The high temperature oxidation resistance of the sample decreases.