1. Improvement of molding operation process

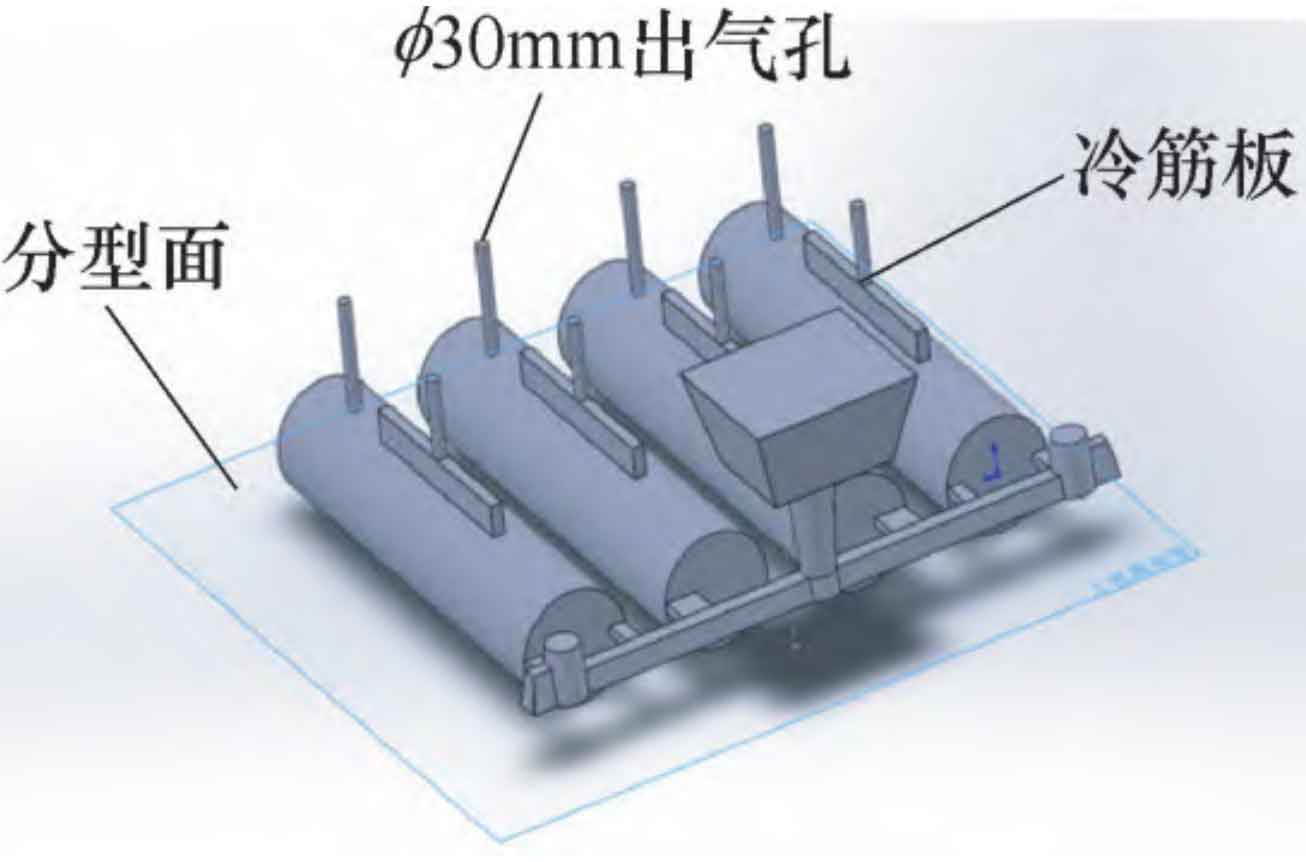

As shown in the figure, change the original parting surface from φ 260mm center parting, symmetrical up and down, greatly reducing the height of the molding sand box. The two boxes are more than enough. After the box is closed, the height is 500 ~ 600mm. The coating is also very convenient, simplifying the on-site operation process, reducing the sand iron ratio and saving the molding cost.

2. Improvement of solidification mode

According to the wide crystallization range of gray cast iron and the graphitization expansion in the solidification process, the original sequential solidification mode is changed, and the internal sprue, air outlet and cold rib plate (see Figure) are used to adjust the heat distribution state to make its heat balance and achieve simultaneous solidification.

3. Improvement of gating system and riser

(1) The pouring system is improved with four pieces in one box. The molten iron enters from one end, and a small concealed riser is placed through the inner sprue. One inner sprue is used for the middle two pieces, and the size is (width) × Height) 80mm × 15mm, two pieces at both ends, two internal sprues, size (width) × Height) 40mm × 15mm, the heat distribution of each piece is relatively uniform, and the section of the inner sprue is flat, which is convenient for timely sealing in the later stage of liquid shrinkage and maximizing the application of graphitization expansion characteristics.

(2) The riser is improved by casting modulus = casting volume / casting surface area, and the modulus of this gray cast iron is calculated to be 5.8cm. The chemical composition analysis of HT250 smelted in a period of time is summarized, and the results are shown in the table.

According to the chemical composition in the table, the carbon equivalent of HT250 is 4.16% ~ 4.23%, and each batch is inoculated. In addition, place a 400mm strip in the middle of the top of gray cast iron × 30mm × (80 ~ 100) mm cold rib plate, and one is set in the middle of the cold rib plate φ 30mm air outlet shall be placed at 1 / 4 of the tail end at the same time φ One 30mm air outlet (see Figure). Use cold rib plate and air outlet to adjust the temperature distribution, balance the heat in the middle and achieve balanced solidification. In addition, the timely closure of the inner sprue maximizes the use of graphitization expansion. According to the above conditions, the gray cast iron can be cast without riser. Gray cast iron casting eliminates the top conjoined feeding riser, which not only overcomes the defects of gray cast iron shrinkage porosity and shrinkage cavity, but also improves the yield and reduces the processing and production cost.

| Element | C | Si | Mn | P | S | Cr | Al | Mg |

| Detection value 1 | 3.45 | 2.084 | 0.157 | 0.0486 | 0.0871 | 0.04 | <0.001 | 0.0015 |

| Detection value 2 | 3.453 | 2.085 | 0.158 | 0.042 | 0.0796 | 0.0398 | <0.001 | 0.0015 |

| Detection value 3 | 3.483 | 2.087 | 0.157 | 0.0463 | 0.0941 | 0.0398 | <0.001 | 0.0021 |