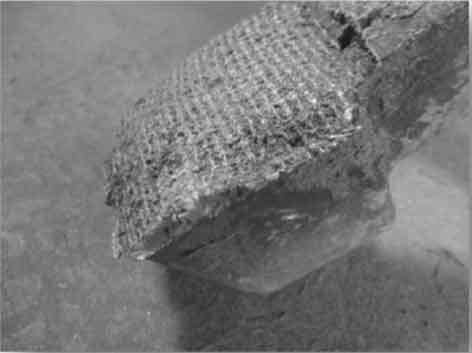

The slag holes are mainly distributed around 2 and 5 turns, accounting for 22.7%; the defect area is large and in pieces. After dissecting the gating system, it was found that many fiber filters used for hot metal filtration were deformed and broken (Fig. 1), which had no effect on filtering molten iron impurities. Instead, the filter screen itself was broken into the mold and became an impurity itself.

The analysis shows that the main source of slag hole is the filter screen. Since the amount of molten iron and pouring time of large crankshaft are more than those of ordinary castings, the filtration capacity of the original fiber filter screen exceeds its own filtering capacity, which is not enough to support the long-term high-temperature scouring of C3000 crankshaft molten iron, resulting in fracture.

Considering the long-term production cost, the selected fiber filter screen is adjusted. Fiber filter screen works in high temperature, high pressure and impact environment. Its maximum working temperature and filtration capacity are important indexes to evaluate the strength of fiber filter. In the high temperature strength test of several kinds of fiber filter screen, the three strand glass fiber filter screen is unique.

Therefore, the production of three strand filter screen instead of the original ordinary glass fiber filter screen becomes a new optimization scheme (as shown in Fig. 2). When the application effect is verified as shown in Fig. 3, no damage is found.