The pouring process of liquid metal involves the phase transformation process of metal. Even on the premise of meeting the requirements of “dense casting”, the performance of local materials of the casting will be different due to different crystallization processes inside the casting; For example, when the riser is used to supplement and shrink the casting, it is easy to find defects such as shrinkage cavity, shrinkage porosity, coarse graphite and loose structure at the root of the riser after unpacking. The main reason for the defects is that after the riser is set, the riser root forms a contact hot joint with the casting, so that too much heat is concentrated in this area, resulting in the solidification lag of the riser root, which affects the quality of the local area after forming.

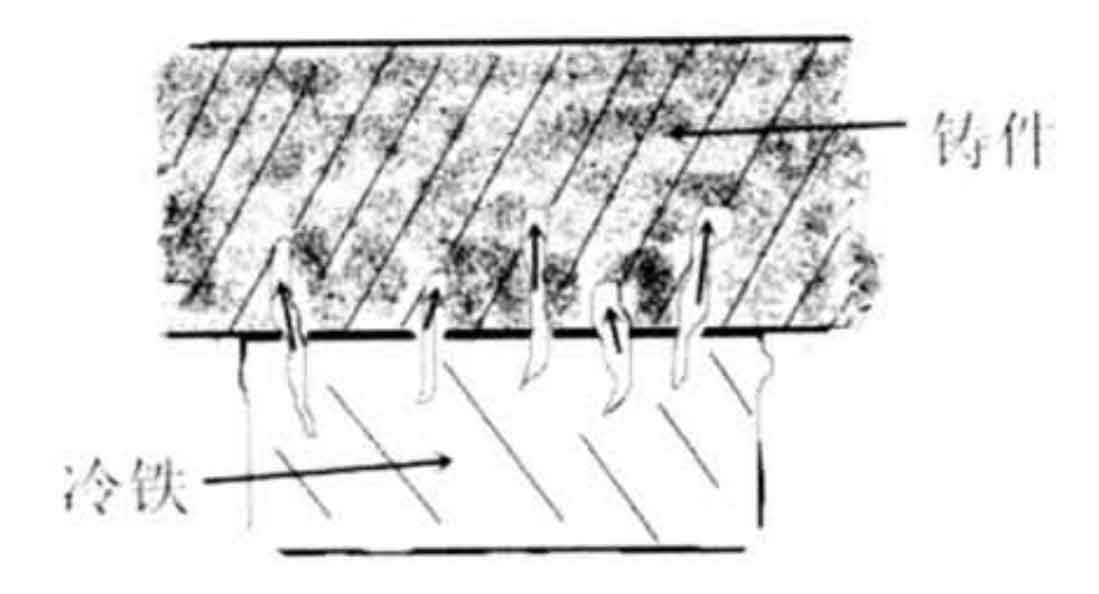

For another example, casting engineers often set chills locally in the casting to eliminate or transfer hot spots and improve the feeding effect of risers or ingates with the help of the chilling effect of chills. However, it is easy to cause air holes, hot cracks and other defects at the contact part between the cold iron and the casting. The main reasons are; In actual production, the processing quality of cold iron is often ignored, resulting in poor apparent quality of cold iron. For example, there is a cavity on the surface of cold iron. During pouring, when the surface of cold iron contacts with high-temperature liquid metal, the gas existing in the cavity will expand rapidly, overflow the surface of cold iron, invade the casting cavity and cause pores. As shown in the figure. Moreover, due to the lack of attention to the preservation of cold iron, iron oxide layer is often attached to the surface of cold iron. During pouring, iron oxide layer will react with carbon in liquid steel to generate gas and cause pores. In addition, the use of cold iron in gray cast iron casting will also make the local microstructure and properties of the casting unfavorable to the induction hardenability, and gradually increase the local hardness of gray cast iron from the inside to the surface, which is unfavorable to the mechanical properties of the casting and the subsequent machining of the blank.

Based on the above reasons, ZHY casting senior engineer team believes that it is necessary to conduct mechanical analysis of working conditions of parts first in casting process design. The reality is; The specific structural design and related structural requirements of parts are only in the hands of mechanical design engineers. When designing the casting structure of parts, the part structure is often simply designed as a structure easy to be cast and processed, and the above many factors are not deeply considered. Casting engineers only aim to obtain “dense Castings”. In addition, casting engineers usually do not understand the actual working conditions of the parts, and lack the detailed information of the structure associated with the parts, so they are unable to understand the weak parts of the parts in detail. Therefore, casting engineers usually simply consider or do not consider the above factors at all. It is precisely because there is no effective communication between the mechanical structure designer and the casting engineer in the casting process design, coupled with their low knowledge of each other’s fields and low data sharing, which hinders the output of high-quality casting products.