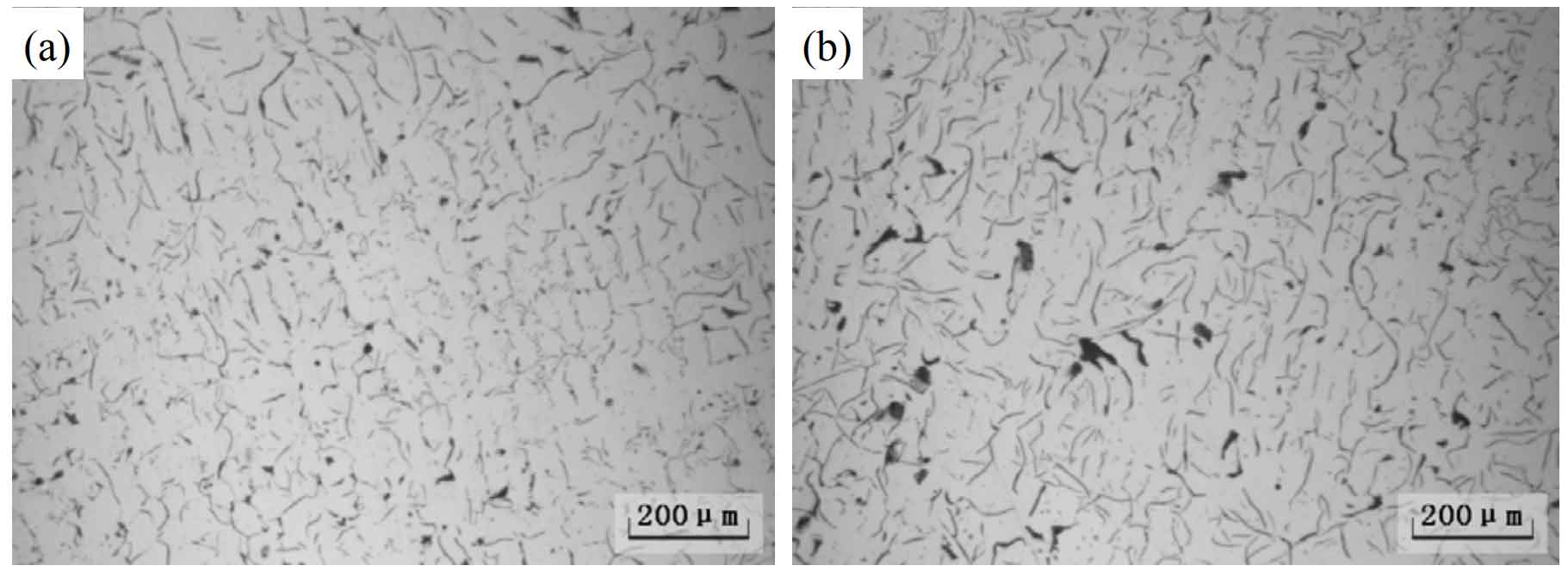

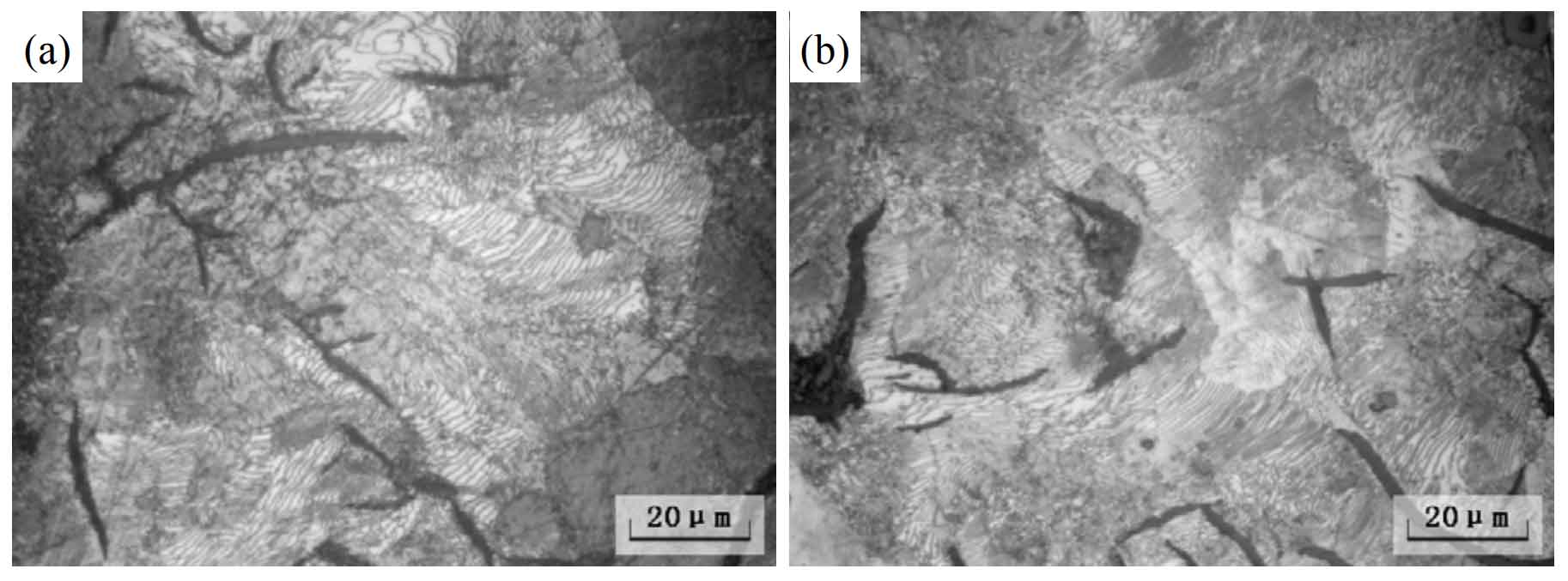

The microstructure of metallographic samples of gray cast iron after polishing and corrosion was analyzed. The graphite morphology is shown in Figure 1; The matrix structure is shown in Figure 2.

It can be clearly observed from Fig. 1 (a) that there are more dot like fine and irregular D graphite, and the larger flake is type a graphite. Therefore, the graphite form of gray cast iron of low titanium pig iron casting sample is a mixture of type a graphite and type D graphite. In Figure 1 (b), the graphite sheet is long, irregular in shape, irregular in growth direction and individual size, evenly distributed, and is type a graphite; Under the condition that the matrix structure is basically the same, the shape and size of graphite in gray cast iron are the main factors affecting the strength of gray cast iron. When the content of Ti element is small (≤ 0.15%), a small part of Ti is dissolved in ferrite, and most of it is precipitated by TiC and tin. When tic and tin reach a certain undercooling degree, it has the role of graphite crystal nucleus, which makes the graphite become fine and forms D-type graphite.

It can be seen from Figure 2 that the matrix structure of the two groups of gray cast iron samples is pearlite. The pearlite content in the picture is higher than 90%. The pearlite sheet spacing in Figure 2 (b) is large; The pearlite sheet spacing in Figure 2 (a) is small. The white bright spot in the figure is that cementite sheets are sporadically distributed on Pearlite sheets, with less content. The structure of cementite layer is flat, the strength is high, and the micro hardness is high, which makes the machinability worse. The smaller the pearlite sheet spacing, the better the mechanical properties such as hardness and strength. This is because the pearlite structure with small sheet spacing hinders the crack propagation, forces the crack propagation to change the direction and consumes more energy.