The testing experiments of nodular cast iron wind power castings include chemical composition testing, mechanical property testing, metallographic structure analysis and fracture morphology scanning analysis.

1.Chemical composition detection of nodular cast iron wind power castings

The chemical composition detection equipment used in the experiment of nodular cast iron wind power castings is German direct reading spectrometer. The effective spectral wavelength range is 140-670nm, with multiple element channels, which can quickly analyze the elements in molten iron. In actual use, first calibrate the equipment with standard samples, then put the pretreated samples on the test bench for testing, measure three points at different positions, and take the average value as the final result. In addition, due to the limitation of the element channel of the direct reading spectrometer, the contents of residual rare earth and residual magnesium were measured by chemical analysis.

2.Mechanical property test of nodular cast iron wind power castings

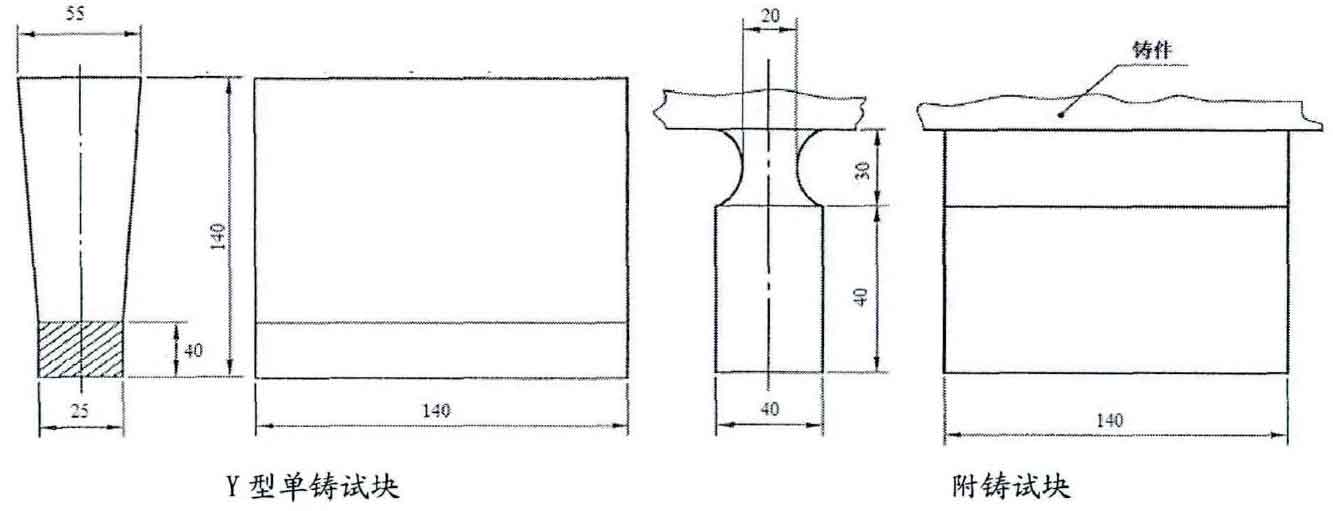

The mechanical properties of nodular cast iron wind power castings mainly include tensile test, impact test and hardness test. The test blocks obtained in the experiment are divided into single cast test block and attached cast test block. Their dimensions are formulated according to GB / t1348-2009 standard. See Figure 1 for specific dimensions.

Refer to GB / t1348-2009 for the processing dimensions of tensile specimens of nodular cast iron wind power castings. See Fig. 2 for specific dimensions.

The tensile test of nodular cast iron wind power castings is carried out by hydraulic universal tensile testing machine, and the measurement parameters are tensile strength and elongation. Before the test, measure the diameter of the test bar with a vernier caliper and calculate the cross-sectional area of the sample. After the test bar is broken, read the maximum tension displayed by the instrument. Finally, the tensile strength is calculated by the formula as follows:

The elongation is calculated by measuring the length of the test bar before and after breaking, and the elongation is recorded as δ n. The calculation formula is as follows:

The processing dimensions of impact samples refer to GB / t1348-2009 standard, and the specific dimensions are shown in Figure 3.

The impact test is carried out by drop hammer impact testing machine. The experimental process is shown in Figure 4.

When simulating the low-temperature environment, a low-temperature tank should also be added to cool the sample first. The low-temperature tank used in this test can be cooled to a minimum of 60 ℃, and the cooling medium is absolute ethanol. During the test, first put the impact sample in the cooling tank for cooling and holding for 30 minutes, and then put it on the impact testing machine for impact test within 3 seconds. During the test of nodular cast iron wind power castings, each temperature point shall be tested three times, and the average value shall be taken as the final result.

The hardness of nodular cast iron wind power castings is measured by Brinell hardness test. Place the steel ball between the known standard part and the tested part, knock it once with a hammer, observe the indentation size of the standard part and the tested part with an observation mirror, and check the table to obtain the Brinell hardness.

3.Metallographic structure analysis of nodular cast iron wind power castings

In the experiment of nodular cast iron wind power casting, the graphite ball and matrix of the sample were observed by optical microscope, and metallographic photos were taken.

4.Scanning analysis of fracture morphology of nodular cast iron wind power castings

Scanning analysis of fracture morphology of nodular cast iron wind power castings the macro and micro morphology of the fracture were observed and photographed by je0l jsm-6380la scanning electron microscope.