The installation test of high chromium cast iron carbon steel bimetallic liner was carried out on the wet ball mill in the beneficiation workshop of Jinshandian Iron Mine subordinate to Wuhan Iron and Steel Mining Co., Ltd. the internal dimension of the mill cabin was 3600mmx6000mm, and the ore production was 160 tons per hour.

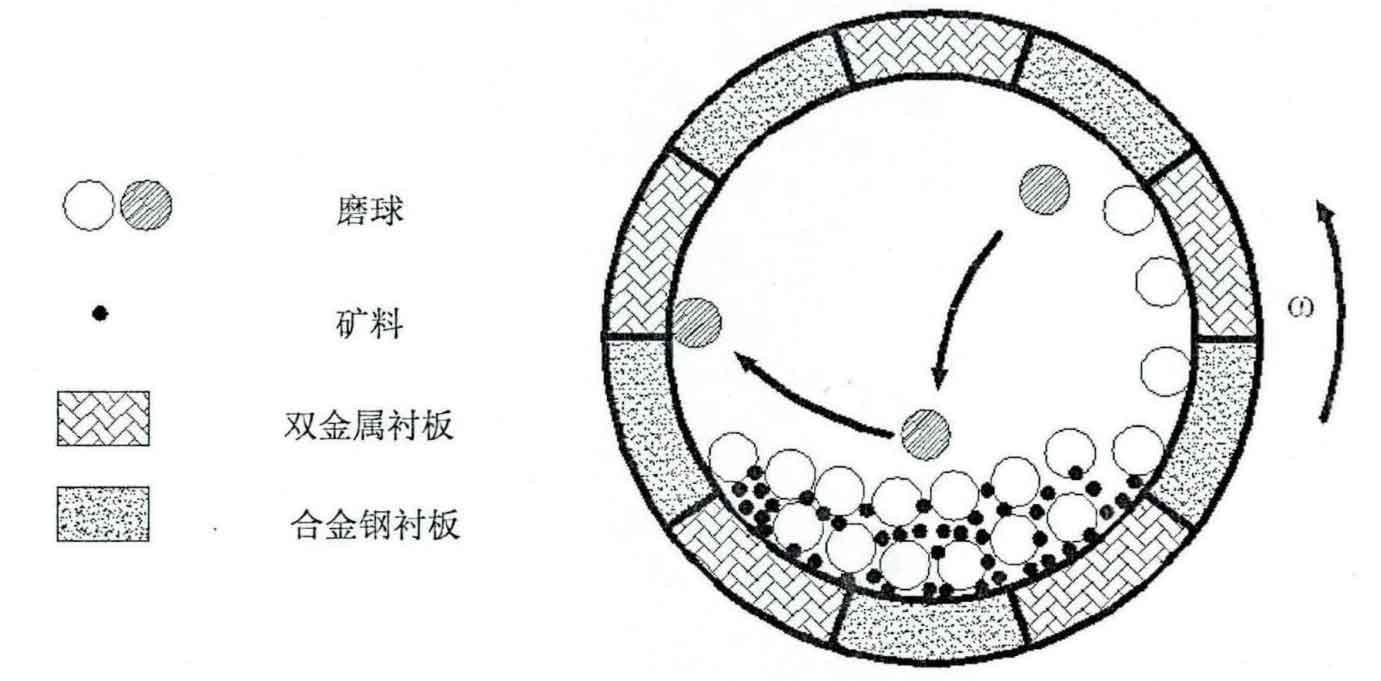

The test principle is shown in the figure. The bimetallic composite lining plate and the original alloy steel lining plate are installed in the ball mill at the same time. When the wet mill works, the lining plate will bear the impact and abrasion of materials and grinding balls in the corrosive pulp environment, resulting in various forms of friction loss of the lining plate. In order to make the two kinds of lining plates subject to uniform impact and wear load under the same conditions during the operation of the ball mill, the two kinds of lining plates are arranged at intervals in the dimensional direction.

The chemical composition of the original alloy lining plate in the workshop is shown in the table below:

| C | Si | Mn | S | P | Cr | Re | B |

| 0.4-0.6 | 0.8-1.1 | 1.0-1.5 | <0.03 | <0.04 | 0.8-1.2 | 0.01-0.015 | 0.005-0.007 |