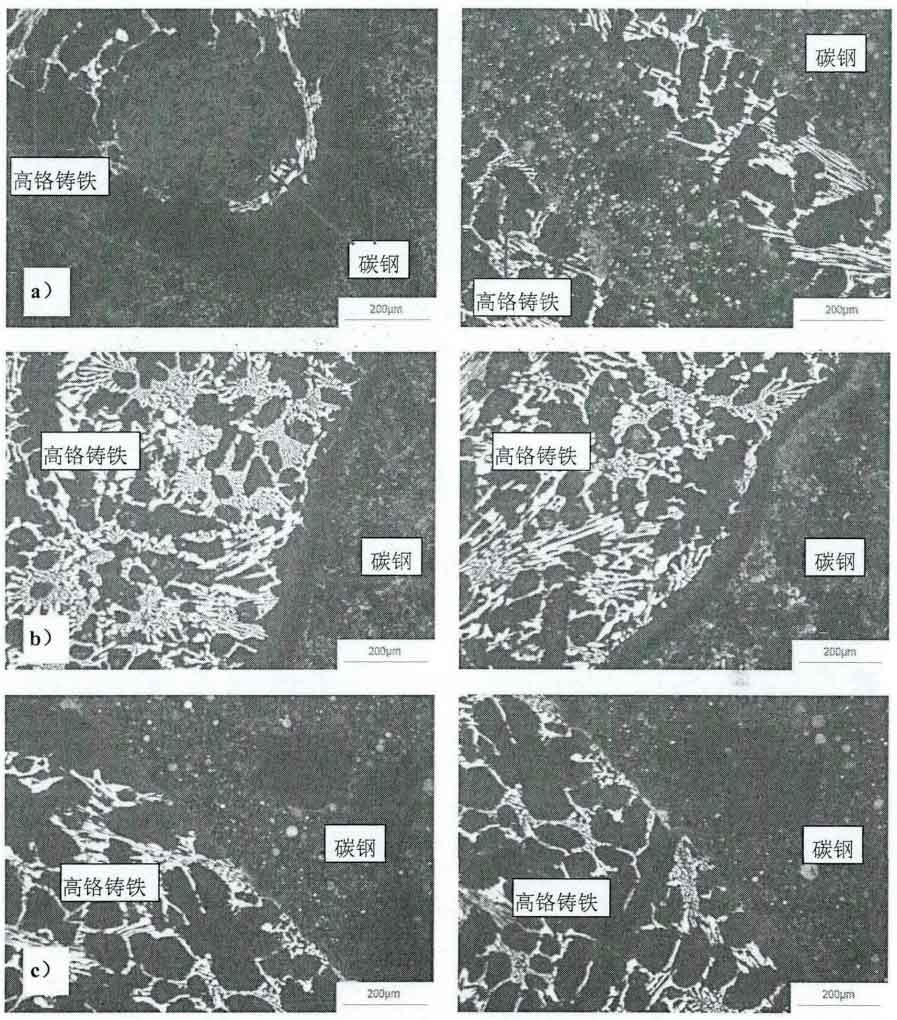

During the preparation of high chromium lining plate in the test, the injection interval is 60s, 75s and 90s respectively. The corresponding metallographic structure is shown in the following figure, which can be observed:

- when the composite pouring time interval is 60s, as shown in figure a, there is no obvious bonding interface between high chromium cast iron phase and carbon steel phase, and the two metal phases enter each other’s space and wrap each other. The reason for this phenomenon is: due to the short pouring interval, the metal temperature of the high chromium cast iron poured first has not reached below the solid phase line or the solidified layer has not reached sufficient thickness, and then the molten steel with extremely high temperature is continuously washed and can completely dissolve the solidified layer of the high chromium cast iron. At this time, the liquid-solid two phases of the carbon steel coexist, As a result, the two kinds of liquid metal mixed disorderly in the composite interface region.

- when the composite pouring time interval is 90s, as shown in Figure C, the two metal phases do not enter each other’s space. There is an obvious bonding interface between high chromium cast iron phase and carbon steel phase, but the bonding interface layer is very thin, almost No. The reason for this phenomenon is: due to the long pouring interval, the metal temperature of the first poured high chromium cast iron completely drops below the solid phase line, and the thickness of the solidification layer of the high chromium cast iron is quite thick. The heat brought by the high-temperature carbon steel molten metal after pouring is consumed by the cold iron effect of the thick high chromium cast iron solidification layer, which is not enough to melt all the surfaces of the solidification layer of the high chromium cast iron, It is difficult to realize the overall metallurgical bonding with sufficient bonding strength and thickness, and only local thin-layer metallurgical bonding and overall mechanical bonding can be formed.

- when the composite pouring time interval is 75s, as shown in Figure B, the two metal phases do not enter each other’s space. There is an obvious bonding interface between the high chromium cast iron phase and the carbon steel phase, and the thickness of the bonding interface layer is up to 0.1mm. This phenomenon can be explained as follows: due to the appropriate pouring interval, The metal temperature of the high chromium cast iron poured in first completely drops below the solid phase line, and the thickness of the solidification layer of the high chromium cast iron is moderate. The heat brought in by the high-temperature carbon steel molten metal poured in later can make the surface of the solidification layer of the high chromium cast iron re soluble or slightly soluble, without two-phase mixing. A high-quality metallurgical bond with sufficient bonding strength, thickness and integrity is formed between the two metals.