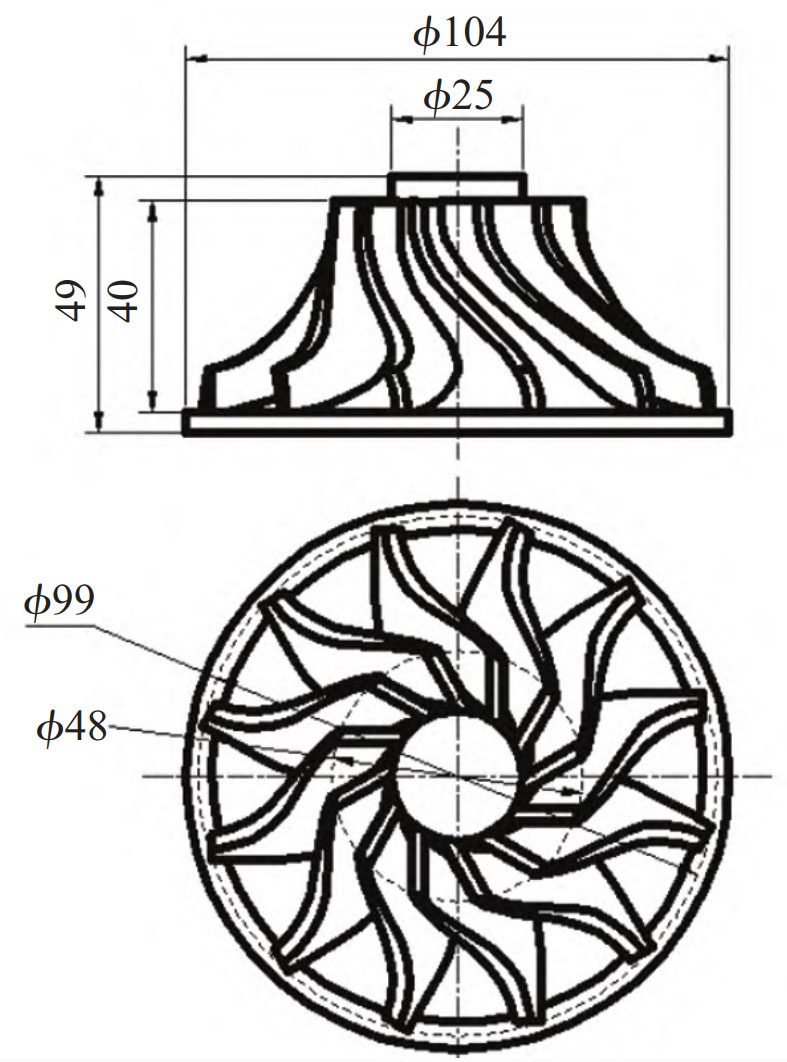

The bottom diameter of the investment casting impeller is 104 mm, the top diameter is 25 mm, and the side width is 49 mm. The shape and main dimensions are shown in Figure 1.

Determine the blade wall thickness size of the impeller as 2.5mm based on the table and workpiece size.

| External dimensions of castings | 10-50 | 50-100 | 50-100 | 100-200 | >350 |

| General wall thickness | 2.0~2.5 | 2.5~4.0 | 3.0~5.0 | 3.5~6.0 | 5.0~7.0 |

| Minimum wall thickness | 1.5 | 2.0 | 2.5 | 3.0 | 4.0 |

Due to the complex shape of investment castings and the curved blades, the interior of the mold cavity is relatively complex, which can lead to unstable pouring process of metal liquid and affect the surface quality and accuracy of impeller investment castings. To avoid this situation, it is important to use CAE software to analyze the impeller before the experiment, providing a theoretical basis for actual production and manufacturing.

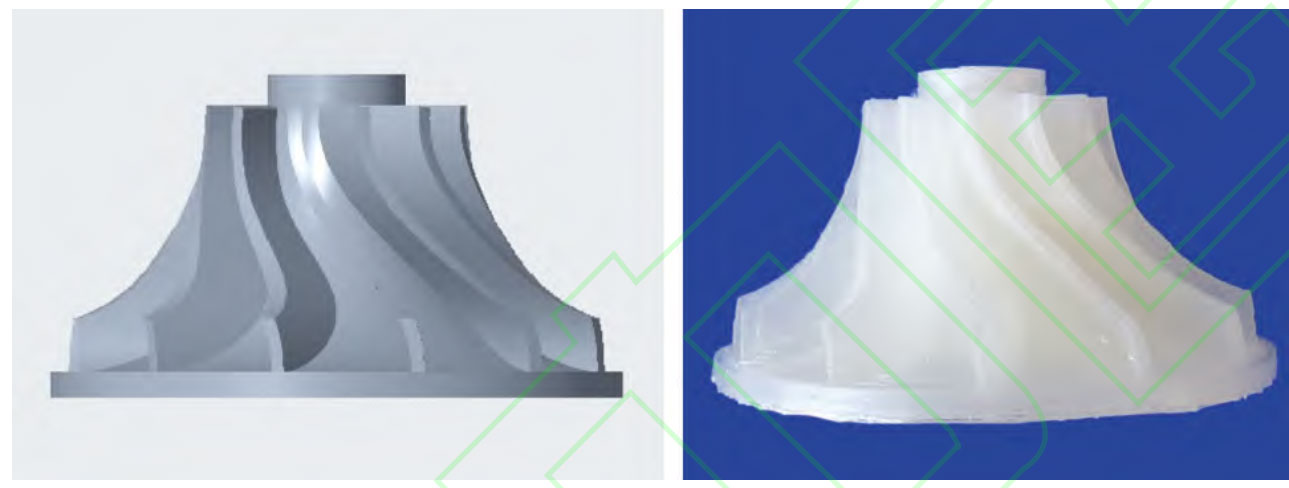

The 3D printing material used in the experiment is polylactic acid (PLA), the pouring metal is ZL104 aluminum alloy, and the pouring temperature is 750 ℃. The shell material is high-temperature resistant gypsum with good fluidity, low thermal conductivity, and high replication accuracy. Figure 2 shows a three-dimensional model of the impeller. Figure 3 shows the printed model of the impeller.