Investment casting is a special type of casting in the field of casting and molding, usually used to make precision and complex parts, and has played an important role in fields such as aviation and industrial gas turbines. The process of investment casting is completed by several steps. Firstly, a wax mold is made, and the shape and size of the wax mold directly determine the dimensional accuracy of the final casting. The wax mold is injected with ceramic slurry and hardened, and then the wax is melted to obtain the mold. Before pouring molten metal, the mold must be dried and preheated to a temperature close to that of the molten metal. After the metal liquid solidifies, the mold is broken, the pouring system is cut, and the final casting is obtained after polishing.

By combining additive manufacturing technology with investment casting technology, 3D printing models are used to replace traditional wax molds as investment molds. On this basis, shell molds are directly made, and then high-temperature roasting is carried out to remove the 3D printing models, which can effectively shorten the development cycle of parts and reduce production costs.

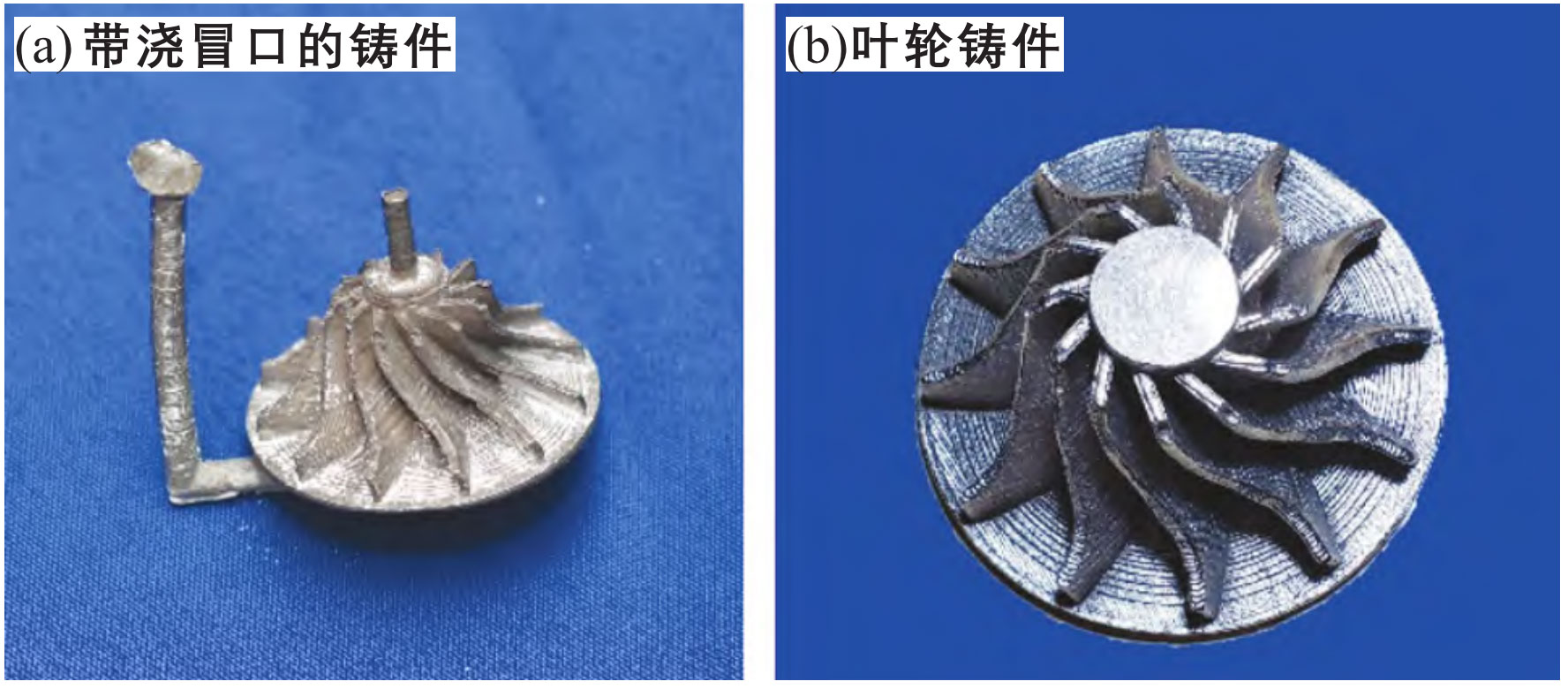

According to the structural characteristics of the impeller, top pouring, side pouring, and bottom pouring systems were designed for the experiment. The three pouring processes were numerically simulated using AnyCasting software, and the optimal pouring system was selected. The investment mold was then printed in 3D, and qualified castings were obtained using the investment casting process.

According to the structural characteristics of the impeller, the rapid prototyping scheme was formulated, and the investment mold was made by 3D printing technology. The aluminum alloy casting of the impeller was successfully made by combining the investment casting process. The experimental results indicate that the investment casting process can effectively combine additive manufacturing technology and obtain excellent castings. This study addresses the casting defects caused by the cumbersome manufacturing process of impeller molds, and is of great significance.