Investment casting is widely used in the manufacturing of core components in fields such as aviation, aerospace, and gas turbines, and requires high dimensional accuracy of castings. High temperature alloy castings often use medium temperature wax and all silica sol shell process, and the dimensional accuracy of the castings produced can reach CT4~CT7 levels. Research has found that the factors that affect the dimensional accuracy of investment castings mainly include casting structure, shrinkage during metal solidification, changes in shell size caused by temperature changes, and dimensional accuracy of investment castings. The impact of dimensional accuracy of investment castings can reach more than 50%.

1. Factors affecting the dimensional accuracy of investment casting

1.1 Types of Mold Materials

Middle and high-end investment castings generally use non filler wax and filler wax to make investment molds. The linear shrinkage rate of non filler wax is about 1%, and the linear shrinkage rate of filler wax is about 0.5%. Research has shown that reducing the linear shrinkage rate is an important way to improve the dimensional accuracy of investment casting. This study used 162 grade non filling wax material, with a linear shrinkage rate of 0.9%~1.0%, which has good formability, stable shrinkage, good flexibility and flexibility, and is suitable for investment casting of thin-walled and small to medium-sized parts.

1.2 Mold making process

A study by Chen Bing from Beihang University found that the higher the wax pressing temperature, the greater the injection pressure, the faster the wax flow rate, the shorter the cooling time, and the higher the mold temperature, the greater the linear shrinkage rate of the investment casting, and the poorer the dimensional accuracy of the casting. Conversely, the higher the dimensional accuracy of the casting. With the gradual improvement of the manufacturing capacity of wax pressing equipment, these molding process parameters can be stably controlled. After multiple pressing tests, combined with the empirical data obtained from the big data intelligent management system, the impact of molding process on the dimensional accuracy of investment casting can be effectively reduced.

1.3 Mold manufacturing accuracy

In recent years, with the rapid development of the mechanical processing industry, traditional precision machining can no longer meet the development needs of cutting-edge technology. Based on this, ultra precision machining technology has been derived, with a maximum machining size accuracy of 10 nm, a surface roughness of 1 nm, and a minimum machining size of 1 nm μ M. At present, more and more intelligent manufacturing technology and network technology are being applied to the field of mechanical processing. At the same time, with the development of optical and electronic technology, the precision of mechanical processing has been greatly improved. In recent years, some specialized mold equipment from abroad has entered China, making mold manufacturing in China more high-speed, precise, composite, and intelligent. The impact of mold manufacturing accuracy on the dimensional accuracy of investment casting is becoming smaller and smaller.

1.4 Investment casting investment structure

Research has found that when the cross-sectional thickness of investment casting exceeds 13 mm, it is recommended to use cold wax blocks to reduce wall thickness, thereby reducing the shrinkage rate of investment casting investment lines. However, using cold wax block technology usually faces the following issues:

① Increased the number of molds, thereby increasing production costs;

② Due to the need for pre fabrication of cold wax blocks, the production efficiency of the product is reduced;

③ When the structure design of the cold wax block is unreasonable, it can lead to uneven shrinkage and size fluctuations in investment casting. Usually, multiple trials and adjustments are required to determine the final structure of the cold wax block;

④ Cold wax blocks are prone to inadequate wrapping or exposed support points, which increases the workload of investment casting repair and reduces the surface quality of investment casting.

In summary, the main factors affecting the dimensional accuracy of investment casting are concentrated on the mold material and investment structure. Reasonable design of investment casting structure is the best solution to improve the dimensional accuracy of investment casting when it is impossible to change the mold material and casting structure. This article designs a hollow investment mold structure to reduce the cross-sectional thickness of the investment mold in investment casting, in order to obtain a more uniform investment mold wall thickness and achieve the goal of reducing the shrinkage of the investment mold line. By reducing the shrinkage rate of the investment mold line, the dimensional accuracy of the investment mold can be effectively improved. The hollow investment mold structure only requires an appropriate increase in the core pulling structure of the mold, without extending the production cycle of the investment mold. It is suitable for investment castings with large wall thickness differences, high dimensional accuracy requirements, and large batches.

2. Experimental materials and methods

2.1 Analysis of investment structure in investment casting

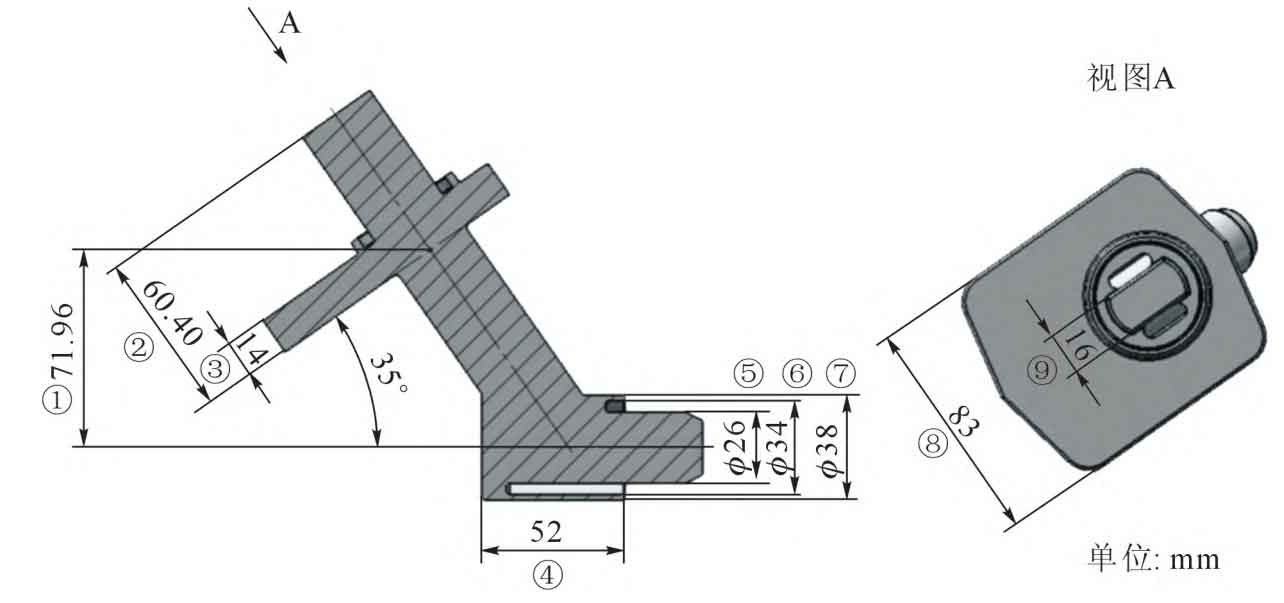

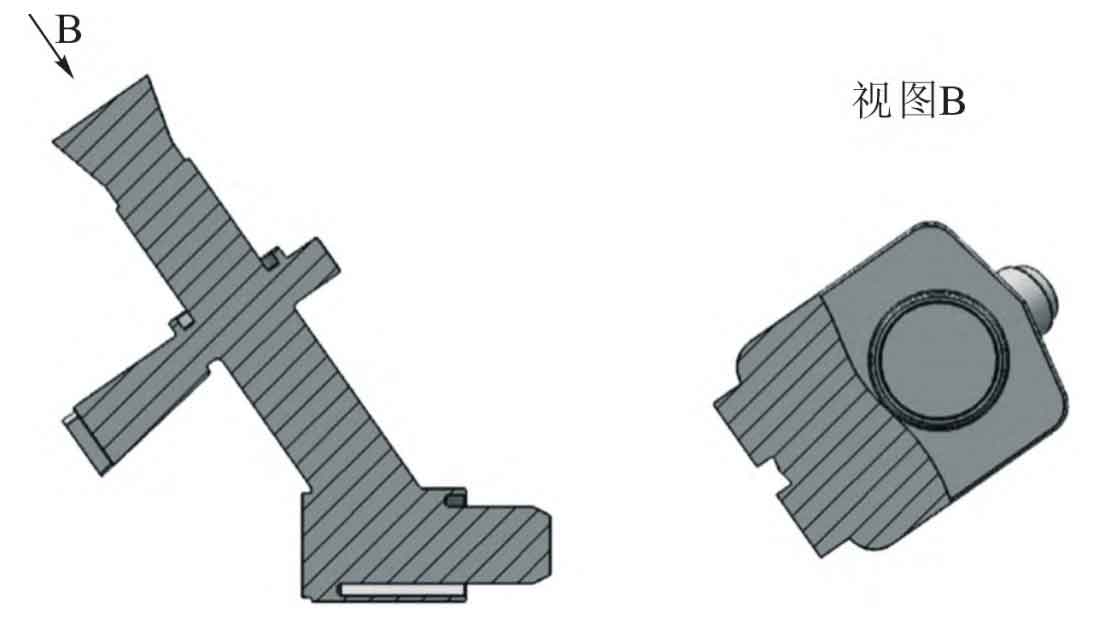

A certain high-temperature alloy casting (Figure 1), material grade K648, chemical composition (mass fraction,%) 0.05 C, 34Cr, 3Mo, 0.85 Ti, 4.45 W, 0.98 Nb, 1.0 Al, with a margin of Ni. This casting belongs to a typical structural investment casting (Figure 1). Except for one “C” – shaped blind hole structure, although the wall thickness difference of the casting is small, the wall thickness of key parts exceeds 13 mm. After the investment casting is pressed, the cooling speed of the contact surface with the mold cavity is the fastest, forming a layer of 3-5 mm solid wax shell first. The heat in the core of the investment casting is difficult to dissipate. When the investment casting is taken out of the mold, The heat from the core gradually transfers outward to the surface of the investment mold, causing the investment mold surface to soften again, which can easily lead to the bending and deformation of the investment mold. The heat transfer from the core of the thick part can also generate significant stress during the outward process, leading to significant linear shrinkage in the traditional investment casting structure (Figure 2), resulting in larger fluctuations in the final casting size.

2.2 Investment casting investment structure design

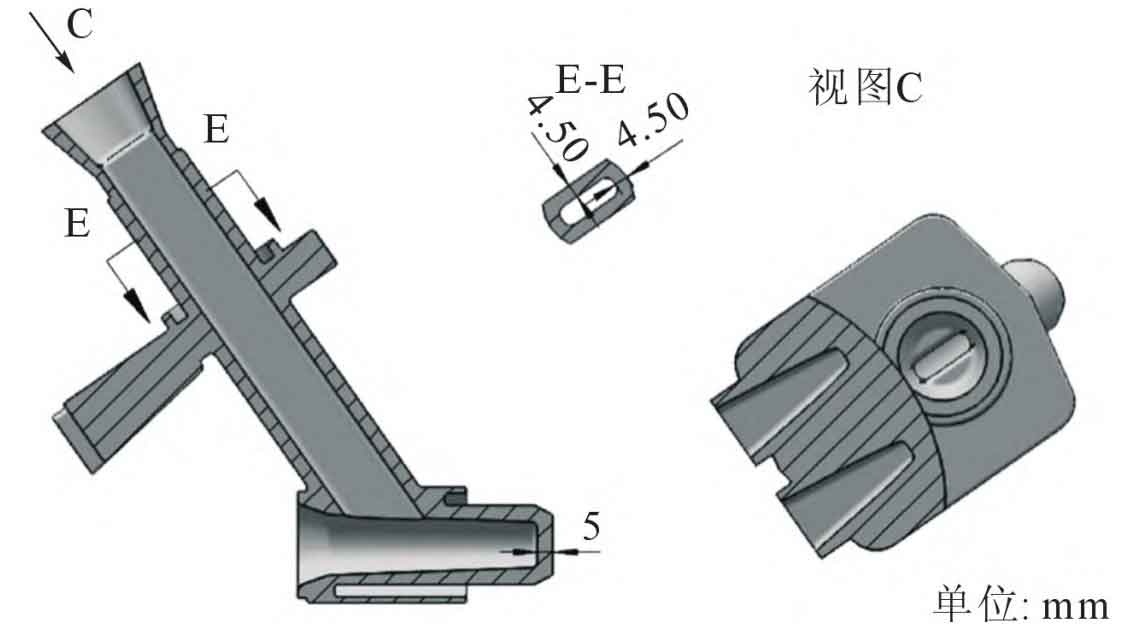

The characteristic of investment casting technology is to prepare castings by replicating the surface shape of the easy to melt mold, and the internal structure of investment casting has no effect on the structure of the castings. Considering the issues with the cold wax block scheme, the investment structure of the test castings is designed as hollow. HB 5350 specifies that the thickness of the linear shrinkage test specimen for investment casting materials is 4 mm, and the thickness of the room temperature bending strength test specimen for the materials is 6 mm. To effectively collect data on the linear shrinkage rate of investment casting and ensure that the investment casting has sufficient room temperature strength, the wall thickness of the hollow section of the investment casting is designed to be 4.5-5.0mm, which also facilitates the flow of wax and the transfer of wax heat. The hollow structure of investment casting needs to be formed by metal mold core pulling. In areas where core pulling is difficult and it is not easy to use an equal wall thickness structure, a conical hollow structure is used, with a single-sided wall thickness of 4.5 mm at the mouth and a 5 ° inward draft angle added to facilitate mold core pulling (Figure 3). Set the open ends of all hollow structures on the gate surface, seal the open ends during investment casting, and ultimately form an investment structure with an internal cavity.

2.3 Mold preparation

The wall thickness of key parts of investment casting for solid structures exceeds 13 mm and belongs to free shrinkage. According to the HB 5350.1 test method, the linear shrinkage rate of 162 wax from the mold to the investment casting investment mold is determined to be 0.5%~1.0%; According to production practice, the comprehensive shrinkage rate of small and medium-sized K648 high-temperature alloy castings from investment casting to casting is 1.6%~2.0%. Therefore, the comprehensive shrinkage rate of the experimental casting mold cavity is initially assumed to be 2.6%, and metal molds are made using the two structures shown in Figures 2-3.

2.4 Preparation of investment molds for investment casting

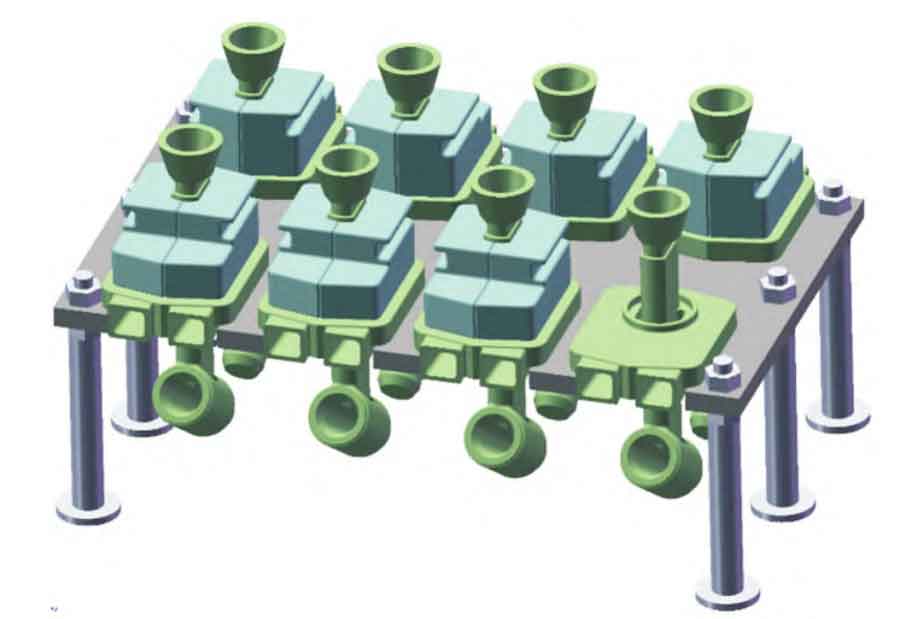

The ash content of the new 162 medium temperature wax material is generally less than 0.05% (mass fraction). With the increase of recycling times and addition ratios, the ash content of the wax material will increase to above 0.10% (mass fraction), ultimately affecting the metallurgical quality of the casting. At the same time, the linear shrinkage rate of recycled wax will also increase to over 1.0%, thereby reducing the dimensional accuracy of investment casting. Therefore, this study used 100% brand new 162 wax material and a 16 ton dual station hydraulic wax injection machine to prepare a melt mold (Table 1). After taking out the investment mold from the metal mold, the investment mold is placed on the straightening platform and straightened with a pressure iron for more than 2 hours (Figure 4) to reduce the deformation of the investment mold.

| Wax injection pressure/(kg · cm^-2) | Wax injection flow rate/% | Wax injection time/s | Wax cylinder temperature/℃ | Cooling cylinder temperature/℃ | Cooling time/s | Pressure holding time of nozzle/s | Molded cooling method |

| 10~20 | 20 | 20~30 | 58±5 | 58±5 | 40~60 | 20~30 | Air cooling |

2.5 Shell production

Produce all silica sol shell according to the process in Table 2, and obtain the experimental shell after using a high-temperature steam dewaxing kettle for dewaxing.

| Hierarchy | Slurry type | Slurry viscosity | Refractory materials | Particle size of refractory materials |

| 1st layer | Zircon powder silica sol | 30-45 s | Zircon sand | 80-120 mesh |

| 2nd layer | Shangdian powder silica sol | 15-25 s | Shangdian sand | 30-60 mesh |

| 3rd to 7th floors | Shangdian powder silica sol | 8-15 s | Shangdian sand | 16-30 mesh |

| 8th layer | Shangdian Powder – Silica Sol | 5-10 s | – | – |

2.6 Casting pouring and post-treatment

The test shell was preheated using a box type resistance baking furnace, and the K648 alloy ingot was remelted and poured using a 25 kg three chamber vacuum induction furnace (Table 3). After pouring, the casting is obtained through cooling, shell cleaning, removal of the pouring system, heat treatment, sandblasting, and other treatments.

| Shell preheating temperature/℃ | Insulation time/h | Pouring temperature/℃ | Pouring speed/s | Vacuum degree/Pa |

| 1 050 | 2 | 1 450 | 10 | 0.05 |

3. Experimental Results and Analysis

3.1 Analysis of investment mold contour dimensions in investment casting

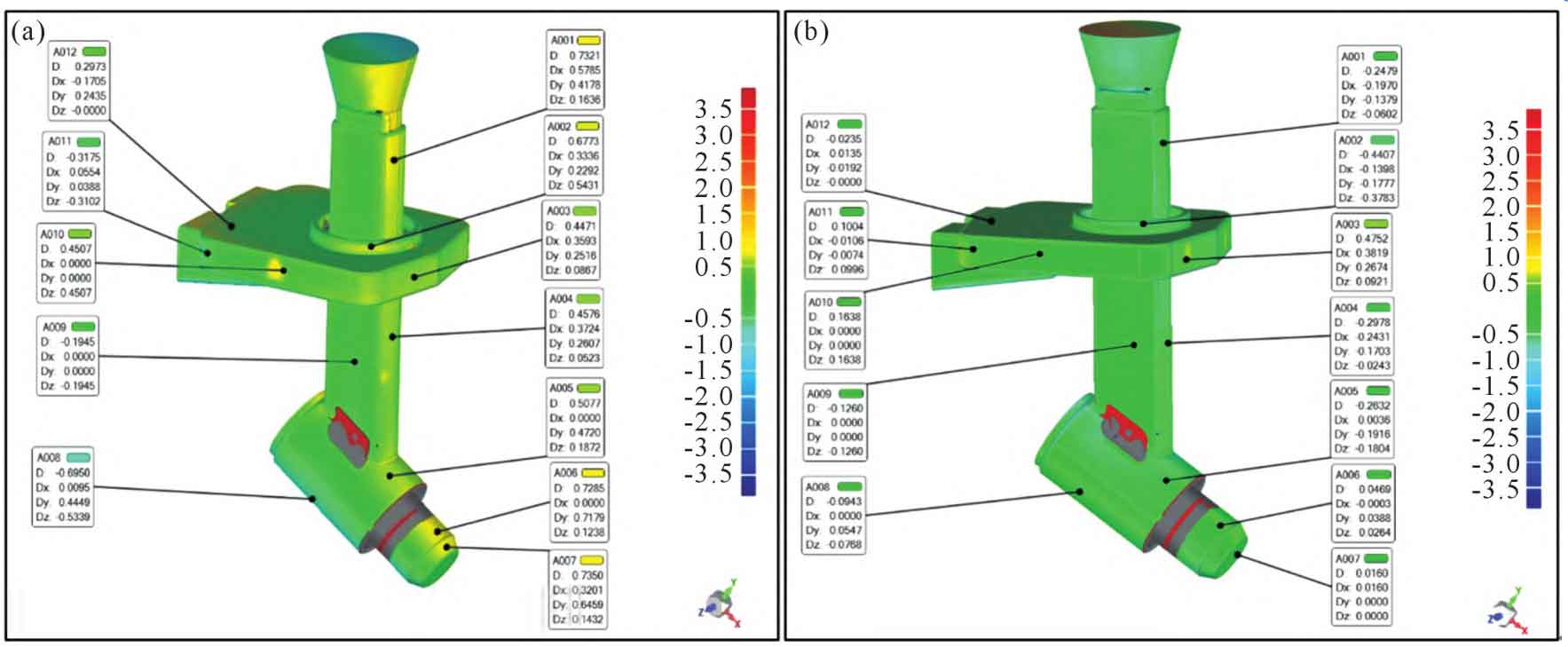

Two types of investment casting molds were scanned using a Geomagic Control blue light scanner, and compared and analyzed with a 3D theoretical model (Figure 5).

The results show that the surface offset of the solid investment mold is -0.695~+0.735 mm, and the surface offset of the hollow investment mold is -0.44~+0.475 mm. At the same time, due to the large wall thickness of the cross-section, there is a significant bending at the far end of the solid investment mold after shrinkage, and the degree of shrinkage in the middle plane is significantly higher than that of the hollow investment mold (position A009 in Figure 5). This is because the decrease in the average wall thickness of the hollow investment mold reduces the heat accumulated during the investment casting process, and reduces the internal stress generated during the cooling shrinkage of the investment mold. Meanwhile, due to the increase in contact area between investment casting and metal molds, the cooling of investment casting becomes smoother and more uniform. It can be seen that by reducing the wall thickness of investment molds larger than 13 mm to 4.5-5.0 mm, the deformation of the easily bent and deformed parts at the far end of investment molds is effectively alleviated, and the shrinkage of the flat core is also alleviated. This is of great significance for improving the dimensional accuracy of investment molds.

3.2 Analysis of Linear Dimensions of Investment Casting

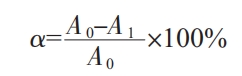

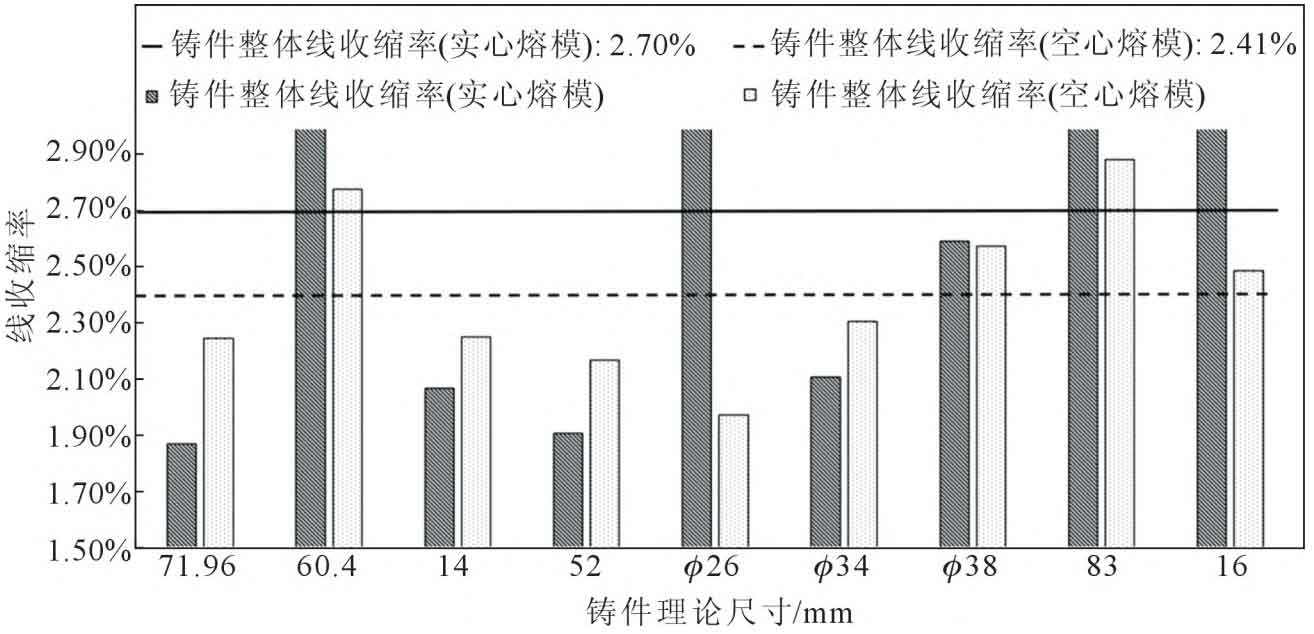

Detect the key dimensions of two types of investment casting molds and calculate the actual linear shrinkage rate according to equation (1) (Table 4). The results show that the average linear shrinkage rate of solid investment molds is 1.16%, and the average linear shrinkage rate of hollow investment molds is 0.54% (Figure 6).

In the formula, α Shrinkage rate of investment line for investment casting; A0 is the size of the mold cavity; A1 is the investment casting investment size.

| Number | Mold cavity size A0/mm | Solid investment mold measured size A1 solid/mm | Shrinkage rate of solid investment line α Real/% | Hollow investment mold measured size A1 empty/mm | Shrinkage rate of hollow mold line α Empty/% |

| 1 | 73.83 | 72.50 | 1.80 | 73.09 | 1.00 |

| 2 | 61.97 | 60.98 | 1.60 | 61.88 | 0.15 |

| 3 | 14.36 | 14.30 | 0.45 | 14.32 | 0.31 |

| 4 | 53.35 | 52.80 | 1.03 | 52.88 | 0.88 |

| 5 | 26.68 | 26.42 | 0.97 | 26.48 | 0.75 |

| 6 | 34.89 | 34.71 | 0.52 | 34.79 | 0.29 |

| 7 | 38.99 | 38.24 | 1.92 | 38.58 | 1.05 |

| 8 | 85.16 | 84.42 | 0.87 | 84.88 | 0.33 |

| 9 | 16.42 | 16.20 | 1.32 | 16.40 | 0.10 |

It can be seen that the linear shrinkage rate of all key dimensions of the hollow investment mold is smaller than that of the solid investment mold. The larger the shrinkage distance during the cooling process of the investment mold, the more significant the decrease in linear shrinkage rate. The linear shrinkage rate of the size where the original investment mold wall thickness is less than the minimum wall thickness of the hollow design of 4.5 mm changes less. This is because these areas have low heat and cooling shrinkage stress. Before the investment mold is removed from the mold, It has been fully cooled and solidified, and there will be no “softening” after the investment casting mold is taken out.

3.3 Dimensional analysis of castings

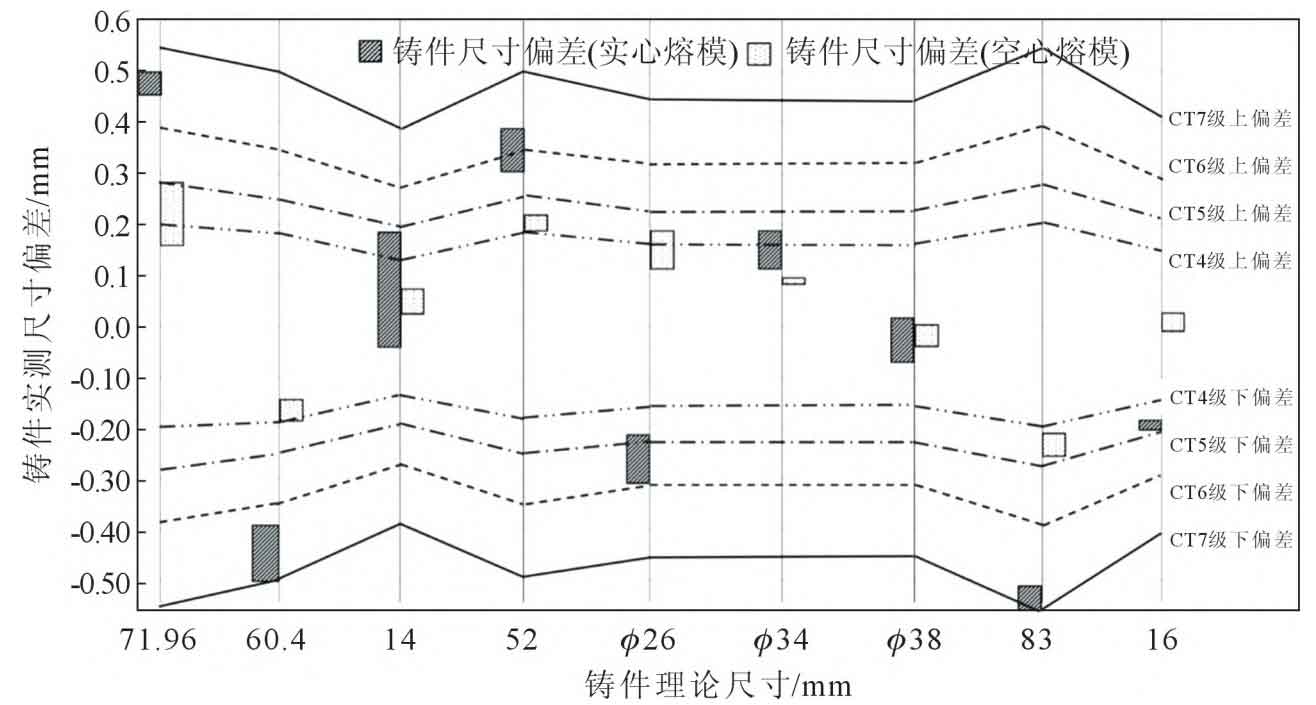

Analyze the dimensional inspection results of castings according to HB 6103 (Table 5). The results show that the dimensional accuracy of castings prepared by solid melt casting meets CT7 level, and the average linear shrinkage rate calculated according to equation (2) is 2.70%; The dimensional accuracy of castings prepared by hollow fusion molding meets CT5 level, and the average linear shrinkage rate calculated according to equation (2) is 2.41% (Figure 7-8).

In the formula, β The actual shrinkage rate of the casting; A0 is the size of the mold cavity; A2 is the size of the casting.

| Number | Mold cavity size A0/mm | Solid investment casting actual measured size A2 solid/mm | Linear shrinkage rate of solid investment castings β Real/% | Actual measurement size of hollow investment casting A2 empty/mm | Linear shrinkage rate of hollow investment castings β Empty/% |

| 1 | 73.83 | 72.45 | 1.87 | 72.17 | 2.25 |

| 2 | 61.97 | 59.97 | 3.23 | 60.24 | 2.79 |

| 3 | 14.36 | 14.07 | 2.07 | 14.04 | 2.26 |

| 4 | 53.35 | 52.33 | 1.91 | 52.19 | 2.17 |

| 5 | 26.68 | 25.71 | 3.62 | 26.15 | 1.97 |

| 6 | 34.89 | 34.15 | 2.11 | 34.08 | 2.31 |

| 7 | 38.99 | 37.98 | 2.60 | 37.98 | 2.58 |

| 8 | 85.16 | 82.47 | 3.15 | 82.69 | 2.89 |

| 9 | 16.42 | 15.80 | 3.73 | 16.01 | 2.49 |

Analysis shows that during the cooling shrinkage process, the solid investment mold of the test casting belongs to free shrinkage, except for the parts in contact with the straightening fixture. The shrinkage is greatly affected by the wall thickness, and the larger the wall thickness, the greater the shrinkage stress, resulting in a significant difference in shrinkage at different positions of the entire investment casting investment mold, leading to larger fluctuations in the size of the casting. After hollow design of investment casting, the wall thickness of investment casting was artificially reduced, and the shrinkage difference at different positions was reduced. The hollow parts were supported by metal cores, and before the investment casting was taken out of the mold, these parts were all subject to restrained shrinkage. Therefore, the size fluctuations of investment casting and castings were relatively small.

4. Conclusion

(1) By designing the section thickness of the solid investment mold to be locally hollowed out at 4.5-5.0 mm and correcting the investment mold for more than 2 hours, the central shrinkage and distal bending of the larger plane of the investment mold can be alleviated, and the overall linear shrinkage of the investment mold can be reduced from 1.16% to 0.54%.

(2) The dimensional accuracy of investment castings has been improved from CT7 level to CT5 level, and the actual linear shrinkage rate of castings has been reduced from 2.70% to 2.41%. This result can provide a reference basis for the casting process design of thick and large investment castings.