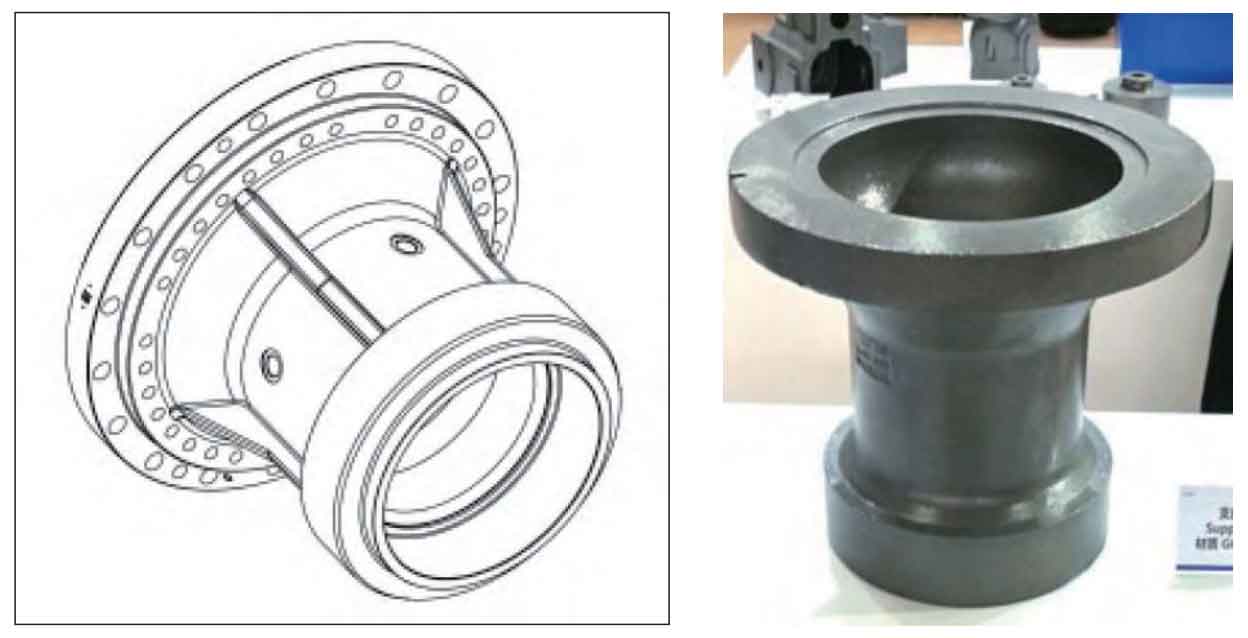

The output shaft shell is wind power, large agricultural equipment Transmission shaft of mechanical equipment such as truck and elevator transmission The bearing shell of (output) supports and contains various transmission parts, such as gears, shafts and bearings. In order to maintain normal motion relationship and motion accuracy, it bears various loads during use. It is an important key component of various equipment and plays the role of framework support. Therefore, its material and internal quality are very important to its service performance. This kind of output shaft shell is produced The product is in the shape of thick large revolving body, with flange structure at both ends, single piece mass of 70 ~ 150kg, large end flange diameter of 400 ~ 450mm and height ≥ 300mm. It has lost foam casting process difficulties of “uneven wall thickness and multiple annular isolated hot joints” unfavorable to casting. The output shaft shell is shown in the figure.

Lost foam casting process is a casting process in which EPS white mold models similar to the size and shape of castings are bonded and combined into mold clusters, coated with refractory materials, dried and buried in ceramsite sand, vibrated and compacted under negative pressure, poured metal liquid under negative pressure to gasify the model, the liquid metal occupies the position of the model, solidified and cooled to form castings, It is called “green casting process in the 21st century”.

(1) It is feasible and suitable to adopt lost foam casting process for output shaft shell.

(2) By adopting the lost foam casting process, the internal structure of the casting is dense, the problems of shrinkage cavity and shrinkage porosity are effectively solved, and the surface quality of the casting is significantly improved to meet the quality requirements of the product.

(3) Give full play to the advantages of EPC forming process, save sand core and cold iron, reduce production cost, reduce post-treatment workload and improve production efficiency.

Adopting EPC forming process can not only give play to its advantages of good casting quality, low cost, small cleaning workload, improving working environment, energy conservation and environmental protection, but also have obvious advantages of EPC process, such as density of casting structure, improvement of mechanical properties and good surface quality. The use of vacuum negative pressure adsorption pouring can further improve the mold filling capacity and liquid metal feeding capacity, compact the internal structure of the casting, and improve and solve the problems of shrinkage cavity and porosity. At the same time, there is no need to lower the overall large sand core, which can significantly reduce the production cost, reduce the workload and improve the production efficiency.

According to the product structure of the output shaft shell, the EPC process design adopts the top injection mode under the condition of appropriately increasing the vacuum negative pressure, and 6 ~ 8 slag collecting bags are set at the highest points on both sides of the inner gate.