In the field inspection, we should focus on the parts prone to casting defects. According to my experience in the quality control of steel castings, for example, the key parts of steel castings (including anchors) for hull structure include: all arc parts, the root of pouring and riser, the tie bar of casting process, slag and sand inclusion parts, the parts with traces of gas cutting and carbon arc gouging, welding repair and repair, the parts that may bear high stress in use, etc. for steel anchors, attention should also be paid to the weld surface defects at the ends of all shaft pins. According to the surveyor of a classification society, there have been cracks and other defects in the welds at the end of the axle pin on seagoing ships, which have been eroded by seawater, resulting in the axle pin falling off and losing anchor after anchoring.

Visual and magnetic particle flaw detection shall be conducted for high stress areas, and sand inclusion and cracked casting defects are not allowed. Other casting defects that affect the service performance of the product (such as shrinkage cavity, cold shut, dense pores, slag inclusion, etc.) are also not allowed. At present, the standard of magnetic particle flaw detection is GB / t9444-2007, and the acceptance level of magnetic particle flaw detection is almost not specified in CCS specification and approved drawings. Referring to relevant materials, in the case of unclear technical requirements in approved drawings, it is suggested that the acceptance level can be determined according to the surface roughness level: the rough machined surface and important parts (such as parts that may bear high stress in use) shall not be lower than SM1 and am1a; Other cast surfaces shall not be less than SM4 and am3c acceptance.

During magnetic particle flaw detection, careful observation shall be made, and suspicious magnetic marks shall not be missed. Some defects are hidden under the skin, and the magnetic trace is not easy to be found without repeated magnetization (as shown in Figure 1). Especially in the inspection of cast steel anchor, the magnetic particle flaw detection link is very important, because the cast steel anchor is no longer machined, the shape of steel castings is very irregular, there are many arc surfaces, and its near surface defects are difficult to be found.

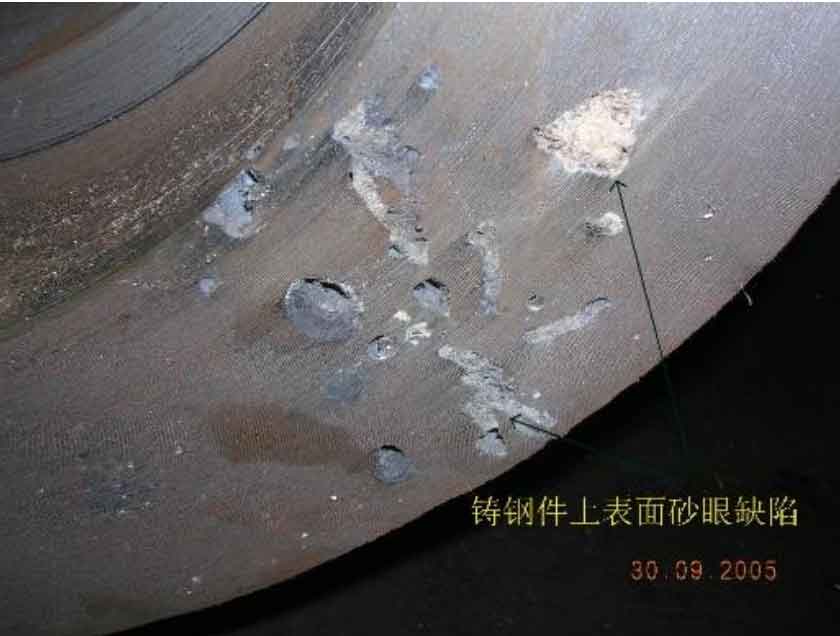

In order to ensure the quality of steel castings for hull structure, it is suggested that the inspection status of important parts of this kind of steel castings should be rough machining. In order to fully expose the defects, the machining allowance (preferably 1 ~ 3mm) should be kept as little as possible during rough machining. This is because some casting defects exist under the skin, which are difficult to find by visual and magnetic particle flaw detection. The surface roughness of casting blank and its near-field area affect the coupling and judgment of ultrasonic flaw detection. As shown in figures 2, 3, 4, 5 and 6, they are all defects found after processing. After rough machining, the casting defects on the near surface can be exposed, and the product surveyor can judge and deal with these defects in the manufacturing enterprise, which not only reduces the workload of the ship surveyor, but also does not affect the ship construction cycle. The important thing is to ensure the quality of the products.