Proper maintenance and regular inspection of gate valve bodies are essential to ensure their longevity and reliable performance. Here are some best practices for the maintenance and inspection of gate valve bodies:

- Follow Manufacturer’s Guidelines: Adhere to the manufacturer’s guidelines and recommendations for maintenance procedures, intervals, and specific requirements. Manufacturers often provide detailed instructions on lubrication, cleaning, and inspection procedures, which should be followed accordingly.

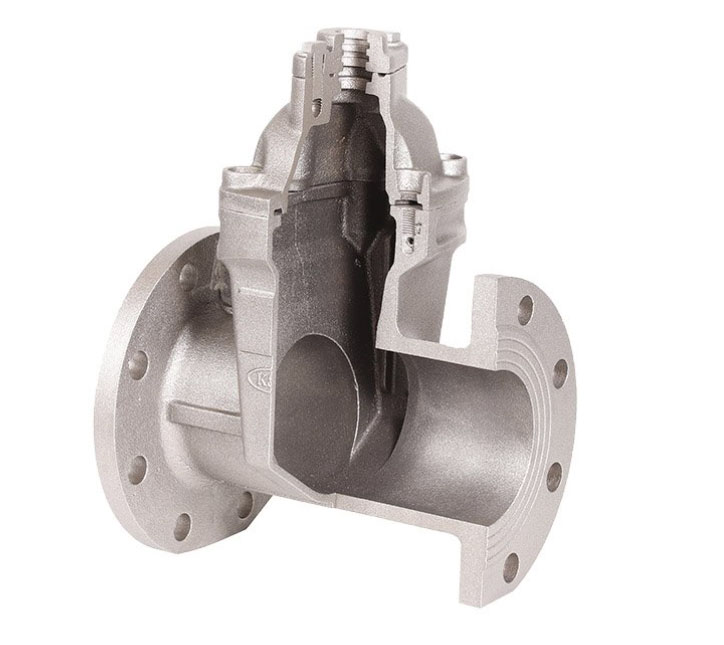

- Routine Visual Inspections: Conduct routine visual inspections of gate valve bodies to identify any visible signs of damage, corrosion, leaks, or abnormal wear. Look for cracks, deformities, loose connections, and signs of leakage around the body, bonnet, and joints. Pay attention to the condition of seals, gaskets, and stem packing.

- Lubrication: Proper lubrication of moving parts, such as stems and gate guides, is essential for smooth operation and to prevent excessive friction and wear. Follow the manufacturer’s recommendations for lubricants and lubrication intervals. Avoid over-lubrication, as it may attract contaminants.

- Stem Seal Maintenance: Check the stem seal, gland packing, or other sealing mechanisms regularly for signs of wear or leakage. Adjust or replace the packing if necessary to maintain proper sealing and prevent fluid leakage. Follow proper procedures for gland tightening to prevent excessive compression or leakage.

- Cleaning and Flushing: Periodically clean the gate valve body and associated components to remove debris, sediments, or contaminants that may affect performance. Flushing the valve with clean water or appropriate cleaning solutions can help remove any accumulated deposits or debris within the valve body.

- Leakage Testing: Conduct regular leakage testing to ensure the integrity of the gate valve body and its sealing components. Perform both upstream and downstream leakage tests to identify any leakage around the gate or seat areas. Follow relevant industry standards and guidelines for leakage testing procedures.

- Stem and Gate Operation: Periodically check the operation of the stem and gate to ensure smooth movement and proper alignment. Verify that the gate fully opens and closes without obstruction or binding. Address any issues related to stiffness, misalignment, or excessive play in the stem or gate.

- Corrosion Protection: Implement appropriate corrosion protection measures based on the valve body material and the operating environment. This may include applying protective coatings, utilizing corrosion-resistant materials, or implementing cathodic protection systems where necessary.

- Record-Keeping: Maintain comprehensive records of maintenance activities, inspections, repairs, and any abnormalities observed during the inspection process. This documentation can help track the valve’s history, identify recurring issues, and facilitate proactive maintenance planning.

- Training and Qualified Personnel: Ensure that maintenance and inspection tasks are performed by trained and qualified personnel who have a thorough understanding of gate valve bodies, their components, and maintenance procedures. Regular training and skill development programs can enhance the effectiveness of maintenance practices.

By following these best practices for maintenance and inspection, gate valve bodies can be kept in optimal condition, ensuring their longevity, reliability, and proper functionality in various industrial applications. Regular maintenance and timely repairs or replacements of components contribute to the overall performance and longevity of gate valves.