Proper maintenance and regular inspection of gate valve bodies are essential to ensure their longevity, reliability, and optimal performance. Here are some best practices for the maintenance and inspection of gate valve bodies:

- Lubrication: Gate valves require proper lubrication to minimize friction and ensure smooth operation. Regularly lubricate the stem, stem nut, and other moving parts using the recommended lubricants specified by the valve manufacturer. Follow the lubrication schedule recommended by the manufacturer to maintain optimal performance.

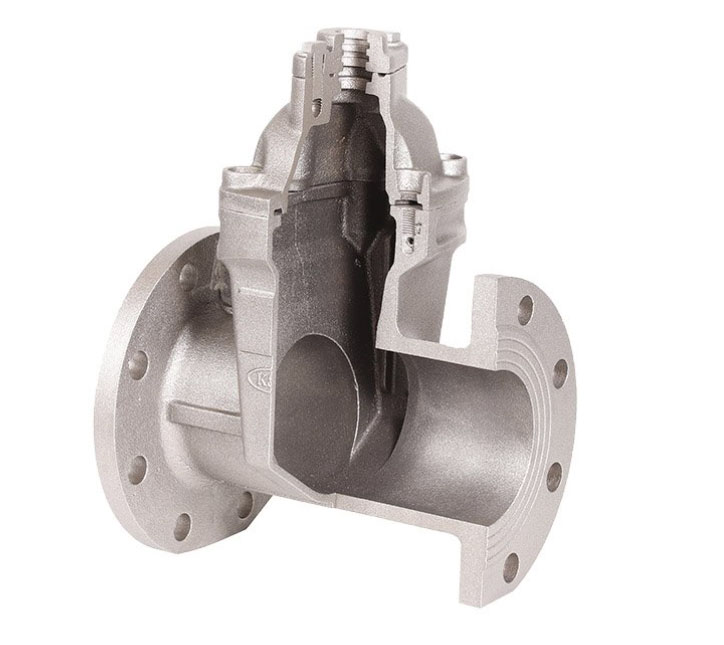

- Visual Inspection: Perform visual inspections of the gate valve body regularly to check for any signs of damage, leaks, corrosion, or external abnormalities. Look for cracks, deformities, or signs of wear on the valve body, bonnet, flanges, and connections. Inspect the valve stem for any bending or damage. Pay attention to the condition of gaskets and seals.

- Operational Testing: Periodically test the gate valve for proper operation. Fully open and close the valve to ensure smooth movement and tight sealing. Check for any sticking or binding during operation. Pay attention to any abnormal noises or vibrations, which may indicate internal problems.

- Leak Testing: Perform leakage tests to identify any leaks in the gate valve body or its connections. This can be done using various methods, including visual inspection, soap bubble testing, or pressure testing. Properly identify and address any leaks promptly to prevent further damage and maintain the integrity of the valve.

- Cleaning and Flushing: Regularly clean the gate valve body to remove dirt, debris, or scale that may accumulate on the surfaces. Flushing the valve with clean water or suitable cleaning agents can help remove any contaminants. Avoid using abrasive materials or harsh chemicals that can damage the valve body or its components.

- Replacement of Seals and Gaskets: Over time, seals and gaskets may deteriorate or lose their effectiveness. Inspect the seals and gaskets for signs of wear, cracking, or deformation. Replace them if necessary to ensure proper sealing and prevent leaks.

- Maintenance Records: Maintain detailed maintenance records for each gate valve body, including dates of inspections, repairs, and replacements. This helps track the maintenance history and allows for better planning of future maintenance activities.

- Follow Manufacturer’s Guidelines: Always follow the maintenance instructions and recommendations provided by the gate valve manufacturer. Manufacturers often provide specific guidelines for maintenance intervals, lubrication requirements, and inspection procedures based on their product specifications. Adhering to these guidelines ensures that the gate valve bodies are maintained properly and in accordance with the manufacturer’s recommendations.

Remember, if you are uncertain or inexperienced in gate valve maintenance, consult with qualified professionals or valve specialists who can provide guidance and assistance in carrying out the maintenance and inspection procedures effectively and safely.