The steel casting industry is an essential component of the global manufacturing landscape, providing critical inputs for sectors such as automotive, construction, energy, and aerospace. As we navigate through 2024, steel casting manufacturers face a complex array of market dynamics and challenges. This article explores these factors, offering a comprehensive overview of the current market conditions and the obstacles steel casting manufacturers must overcome.

1. Market Dynamics for Steel Casting Manufacturers in 2024

Global Demand Trends: The demand for steel castings is influenced by trends in key end-user industries. For instance, a resurgence in construction activities, especially in emerging economies, and a rebound in the automotive industry are driving the demand for steel castings.

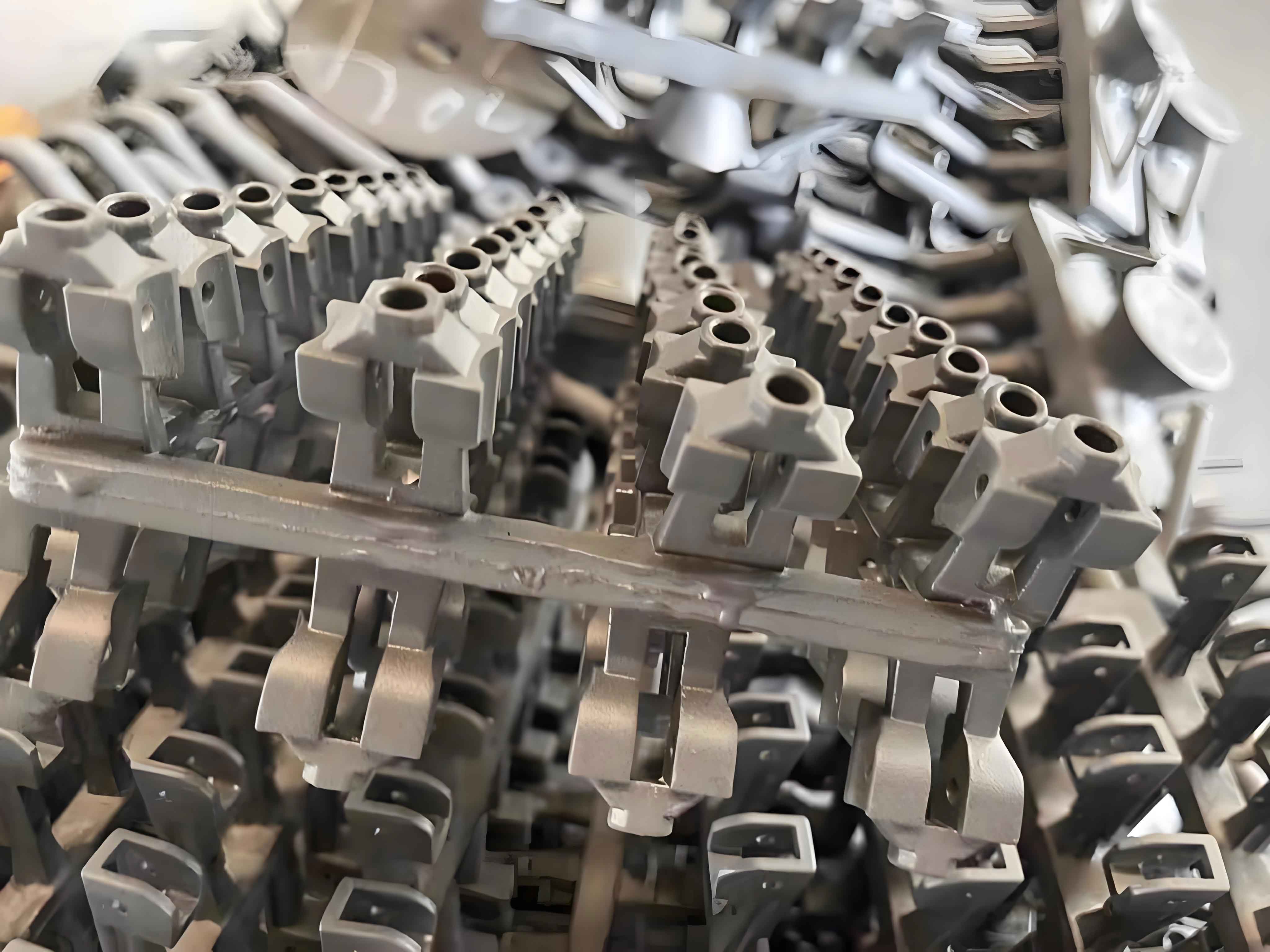

Technological Advancements: Technological innovation remains a significant driver in the steel casting industry. Advancements in manufacturing technologies, such as 3D printing and automation, are reshaping production processes, leading to higher efficiency and lower costs.

Supply Chain Fluctuations: Steel casting manufacturers continue to deal with volatility in raw material costs and supply chain disruptions, partly due to geopolitical tensions and trade policies. The ability to manage these fluctuations effectively is crucial for maintaining profitability.

Environmental Regulations: Increasingly stringent environmental regulations are pushing steel casting manufacturers to invest in cleaner, more sustainable processes. This shift not only impacts operational costs but also opens up opportunities in markets that value sustainability.

Table 3 provides an overview of the key market drivers affecting steel casting manufacturers in 2024:

| Market Driver | Impact on Steel Casting Manufacturers |

|---|---|

| Economic Recovery | Increases demand across multiple sectors. |

| Technological Change | Requires investment in new technologies. |

| Environmental Policies | Promotes eco-friendly production methods. |

| Global Supply Chains | Demands more robust supply chain strategies. |

2. Challenges Facing Steel Casting Manufacturers

Cost Management: The fluctuation in raw material prices, especially steel and energy costs, poses a significant challenge. Steel casting manufacturers must find ways to mitigate these cost pressures to maintain margins.

Workforce Skills Gap: There is a growing need for skilled workers who can operate advanced manufacturing equipment. The skills gap could limit the ability of manufacturers to scale operations and improve productivity.

Quality Control: Maintaining high-quality standards is crucial for steel casting manufacturers, especially as they face increasing competition from global players. Implementing and maintaining rigorous quality control processes is both a challenge and a necessity.

Regulatory Compliance: Adhering to international and local regulations regarding emissions, waste management, and worker safety can be costly and complex, particularly for smaller manufacturers.

Innovation Pressure: Staying competitive requires continual innovation, not just in products but also in processes and business models. This pressure is compounded by the fast pace of technological advancements.

List of challenges currently faced by steel casting manufacturers:

- High operational costs due to raw material price volatility.

- Difficulty in recruiting and retaining skilled personnel.

- Need for continuous improvement in quality control measures.

- Compliance with stringent environmental and safety regulations.

- Necessity to innovate continuously to stay ahead in the market.

3. Strategies for Overcoming Challenges

Cost Efficiency Programs: Implementing lean manufacturing principles and investing in automation can help reduce production costs and improve efficiency.

Training and Development: Investing in employee training programs to bridge the skills gap and enhance workforce productivity.

Quality Enhancement Initiatives: Utilizing advanced quality control technologies, like real-time monitoring and predictive maintenance, can help ensure product quality and reduce defects.

Sustainability Practices: Adopting green manufacturing practices and recycling initiatives can help meet regulatory requirements and appeal to environmentally conscious customers.

Innovation Focus: Collaborating with technology providers and academic institutions to foster innovation can lead to breakthroughs in product and process improvements.

Conclusion

Steel casting manufacturers in 2024 are navigating a complex market landscape marked by opportunities and challenges. By understanding and responding effectively to these dynamics, manufacturers can position themselves for success in an increasingly competitive and globalized market. The ability to adapt to technological changes, manage costs, maintain quality, and meet regulatory demands will define the leaders in this crucial industry.