Gray cast iron is mainly composed of matrix structure and graphite, and others include eutectic, carbide and cementite eutectic. Its microstructure determines its performance. When observing its metallographic structure, it is mainly analyzed and studied from the aspects of flake graphite, metal matrix and eutectic at grain boundary.

The stable state of metal is the state with the lowest free energy. When the metal solidifies, its free energy increases. The actual crystallization temperature must be lower than the theoretical crystallization temperature to produce phase change energy in order to make the solidification proceed. Therefore, in the solidification process of molten iron, the temperature does not solidify when it reaches the melting point, but must be reduced to a temperature below the melting point, that is, a certain degree of undercooling is required in the solidification process.

When the carbon equivalent solidifies in the molten iron near the eutectic composition, primary graphite or primary austenite will be formed. Because the heterogeneous nucleation of graphite requires lower undercooling than homogeneous nucleation, and there are a lot of impurities in molten iron, the nucleation of graphite is heterogeneous nucleation. The nucleation of austenite occurs preferentially at the mold wall or on the surface of other solid impurities in the melt, and takes carbides, nitrides and other carbon nitrogen compounds as the core.

(1) Graphite in gray iron castings

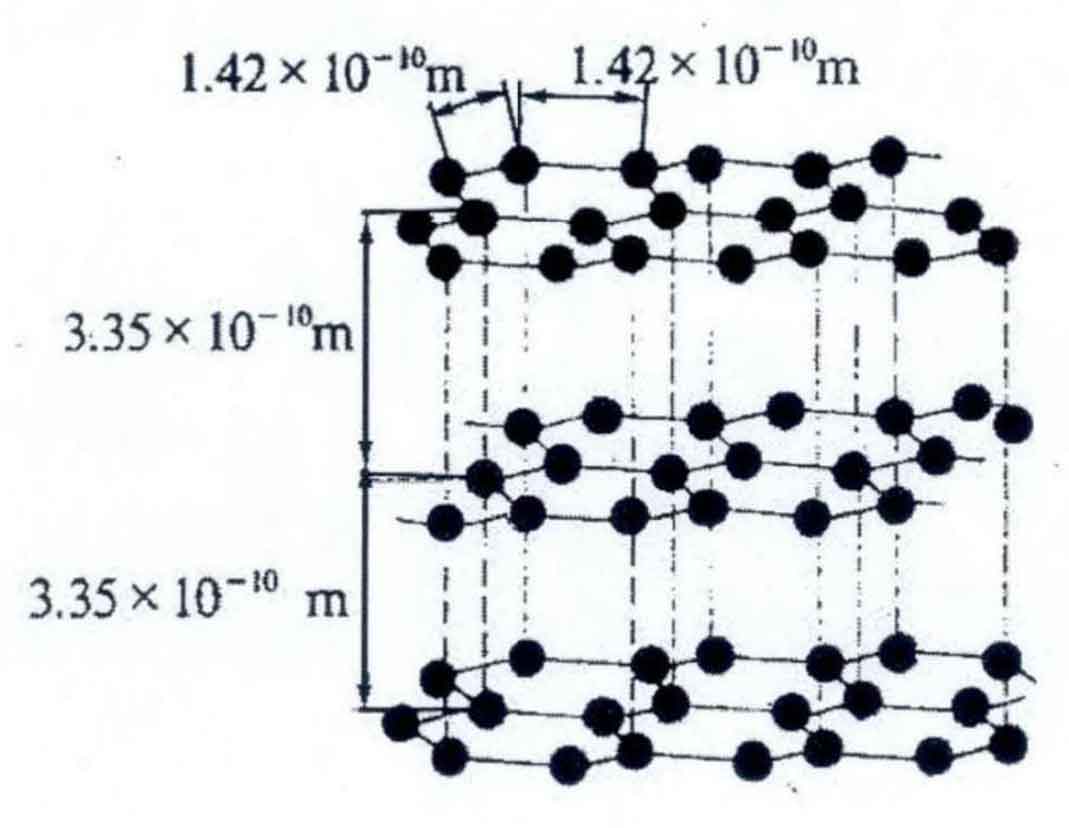

The graphite structure in gray cast iron is shown in the figure. Its characteristics are strength, plasticity, low hardness, soft and brittle. The density is about 2.25g/cm3, about 1 / 3 of iron, that is, about 3% of free carbon can form graphite accounting for 10% (volume ratio) in cast iron. Graphite exists in the matrix of air cast iron, which is equivalent to crack defects, which will significantly reduce its strength and make the performance can not be brought into full play, but it is conducive to improve the shock absorption and wear resistance of gray cast iron. The effect of graphite on the matrix structure is mainly related to the state, size, quantity and distribution of graphite.

(2) Matrix structure of gray cast iron

The main structure of ferritic gray cast iron is that there are many coarse graphite flakes on the ferritic matrix, which has low mechanical properties and small application range; Pearlitic gray cast iron is mainly composed of pearlitic matrix with uniform and fine graphite flakes. Its mechanical properties are relatively different. It is often used to manufacture important parts such as bed and body; Pearlitic ferritic gray cast iron is a kind of coarse graphite flakes distributed on the matrix of pearlitic and ferritic Haihe. Although the mechanical properties of this kind of cast iron are lower than pearlitic grey cast iron, it can still meet the requirements of general engine body. It has good castability and shock absorption and has a wide range of applications.